12

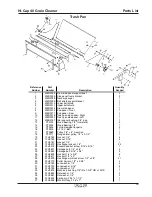

Parts List

Hi-Cap 40 Grain Cleaner

Reference

Part

Quantity

Number

Number

Description

Needed

1

202C0137

Auger Tube, 7"

1

2

202C0410

7 OD Auger, 8'

1

3

202E0006

Power Cord (Specify 115 Volt or 230 Volt)

1

4

204C0010

Auger Pivot

1

5

205C0002

2" Strap Bracket

1

6

205C0003

Motor Mount Angle

1

7

205C0005

Motor Mount Base Plate

1

8

205C0008

Auger Head

1

9

205C0012

Motor Belt Shield

1

10

205C0016

Tail Cage Hopper

2

11

205C0022

Latch and Glide Rod Support

1

12

205C0025

Glide Rod

2

13

205C0027

Hopper Wheel Bracket

1

14

205C0030

Glide Rod Guide

1

15

205C0031

Right Sliding Hopper Sheet

1

16

205C0032

Left Sliding Hopper Sheet

1

17

205C0038

Sliding Hopper End Sheet

1

18

205C0039

Stub Shaft

1

19

205C0040

Flow Restrictor Strap Bracket

1

20

205C0043

Flow Restirctor Adjustment Handle

1

21

205C0044

Flow Restrictor Tube

1

22

2FH0428

Adj. Screw, 5/16 x 7/8

1

23

205C0056

Right End Glide Rod Guide

1

24

205C0057

Left End Glide Rod Guide

1

25

205C0060

Flow Restrictor Strap Bracket, Without Nut

1

26

PT0203

Bearing, Sealed With Eccentric Lock, 1"

1

27

PT0219

Wood Bearing, 1-1/4" Bore

0

28

PT0401

Collar, Eccentric Lock, 1"

2

29

PT0420

2 Hole Bearing Mounting Flange

1

30

PT0424

3 Hole Center Flange Mount

1

31

PT0490

B-48 V-Belt

1

32

PT0681

Pulley, 1" x 12", B Section

1

33

PT0706

Motor Drive Pulley, 5/8" x 3", B Section

1

34

MS0021

6" Rubber Wheel

1

35

1EL0401

Connector, 3/8"

1

36

1EL0667

Plug, 125 Volt, 30 Amp.

1

1EL0668

Plug, 230 Volt, 20 Amp.

1

37

3EL5097

Motor, 1-1/2 HP, TEFC, Electric

1

38

1FH0736

Lock Nut, 3/8"

2

39

1FH0738

Lock Nut, 1/2"

1

40

1FH0764

Hex Nut, 5/16"

11

41

1FH0765

Hex Nut, 3/8"

11

42

1FH0767

Hex Nut, 1/2"

2

43

1FH0995

Hex Flange Whiz Lock Nut, 1/4"

16

44

2FH0512

Socket Head Set Screw, 5/16" x 5/16"

3

45

2FH0645

Carriage Bolt, 5/16" x 3/4"

7

46

2FH0659

Carriage Bolt, 3/8" x 3/4"

7

47

2FH0747

Pan Head Machine Screw, 1/4" x 1/2"

16

48

2FH0828

Hex Bolt, 5/16" x 3/4"

1

49

2FH0830

Hex Bolt, 5/16" x 1"

4

50

2FH0856

Hex Bolt, 3/8" x 1-1/4"

8

51

2FH0913

Hex Bolt, 1/2" x 3-1/2"

1

52

2FH1057

Hex Bolt, 3/8" x 1-3/4", Grade 5

2

53

3FH0712

Cotter Pin, 1/8" x 3/4"

2

54

3FH0714

Cotter Pin, 1/8" x 1-1/4"

3

55

3FH0730

Cotter Pin, 3/16" x 1-1/4"

1

56

3FH0770

Cotter Hair Pin, 1/8" x 2-3/8"

2

57

3FH0790

Lock Washer, 5/16"

12

58

3FH0791

Lock Washer, 3/8"

7

59

3FH0864

Flat Washer, 5/16"

9

60

3FH0865

Flat Washer, 3/8"

4

61

3FH0952

Flat Washer, 5/8" SAE

3

62

3FH1015

Square Key, 3/16" x 1"

1

63

3FH1026

Square Key, 1/4" x 1"

1

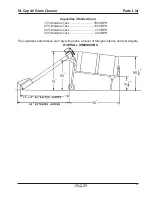

8” x 8’ Auger Parts List

Summary of Contents for HI-CAP 40

Page 1: ...OWNER S MANUAL HI CAP 40 GRAIN CLEANER PNEG 1146 Date 9 21 06 PNEG 1146...

Page 2: ......

Page 15: ...9 Parts List Hi Cap 40 Grain Cleaner MODEL 40 HI CAP GRAIN CLEANER PARTS...

Page 17: ...11 Parts List Hi Cap 40 Grain Cleaner 8 x 8 Auger...

Page 19: ...13 Parts List Hi Cap 40 Grain Cleaner 4 x 15 Fines Auger...

Page 20: ...14 Parts List Hi Cap 40 Grain Cleaner...

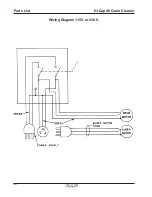

Page 22: ...16 Parts List Hi Cap 40 Grain Cleaner Wiring Diagram 115V or 230 V...