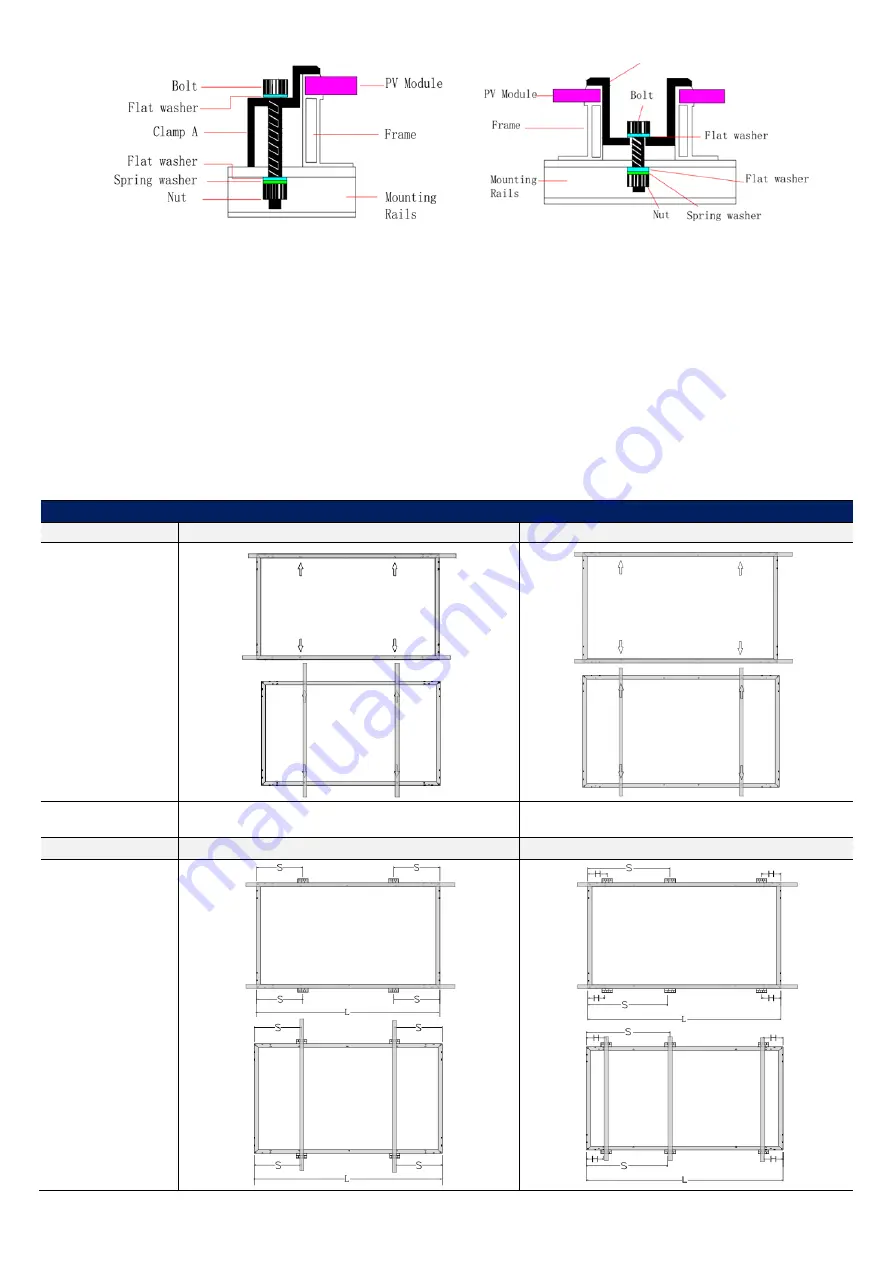

figure4 figure 5

6.3 Test Loads and Design Loads

•

The Standard/lower loading capacity applies to normal

environment: the modules are tested under a maximum

positive pressure of 2400 Pa, and negative pressure of

1600 Pa, the modules are designed to meet a maximum

positive pressure of 1600Pa, and negative pressure of

1067 Pa, this design load was then tested with a safety

factor of 1.5 times.

•

The high loading capacity applies to severe environment,

like storm, big snow, etc. The modules are tested under a

maximum positive pressure of 5400 Pa, and negative

pressure of 2400 Pa, the modules are designed to meet a

maximum positive pressure of 3600 Pa, and negative

pressure of 1600 Pa, this design load was then tested with

a safety factor of 1.5 times.

•

For bifacial double-glass modules, it is recommended

that the beam is installed parallel to the long frame to

reduce backside shielding.

M10-60H / 66H / 72H / 78H & M10-B/G-60H / 66H / 72H / 78H

Installation method

4 bolts at the long frame (60H inner holes)

4 bolts at the long frame (66H/72H/78H outer holes)

Bolt installation

Loading capacity

Test load: positive 3600Pa, negative 2400Pa

Design load: positive 2400Pa, negative 1600Pa

Test load: positive 3600Pa, negative 2400Pa

Design load: positive 2400Pa, negative 1600Pa

Installation method

4 clamps at the long frame

6 clamps at the long frame

Clamp installation