DMEGC Solar PV Modules Installation Manual

•

Do not place connectors in locations where water could

easily accumulate.

5.2 Grounding

•

Although the modules are certified to Safety Class II, we

recommend them to be grounded and that module

installation should comply with all applicable local

electrical codes and regulations. Minimum size of

equipment grounding conductors for ground raceway and

equipment should be considered. Grounding connections

should be installed by a qualified electrician. Connect

module frames together using adequate grounding cables:

the use of 4-14 mm² (AWG 6-12) copper wire is

recommended. Holes provided for this purpose are

identified with a grounding symbol

(IEC 61730-1).

All conductive connection junctions must be firmly fixed.

•

Do not drill any extra ground holes for convenience as this

will void the modules warranty.

•

All bolts, nuts, flat washers, lock washers and other

relevant hardware should be made of stainless steel,

unless otherwise specified.

•

DMEGC Solar does not provide grounding hardware.

•

The grounding method described below is commended

by DMEGC Solar.

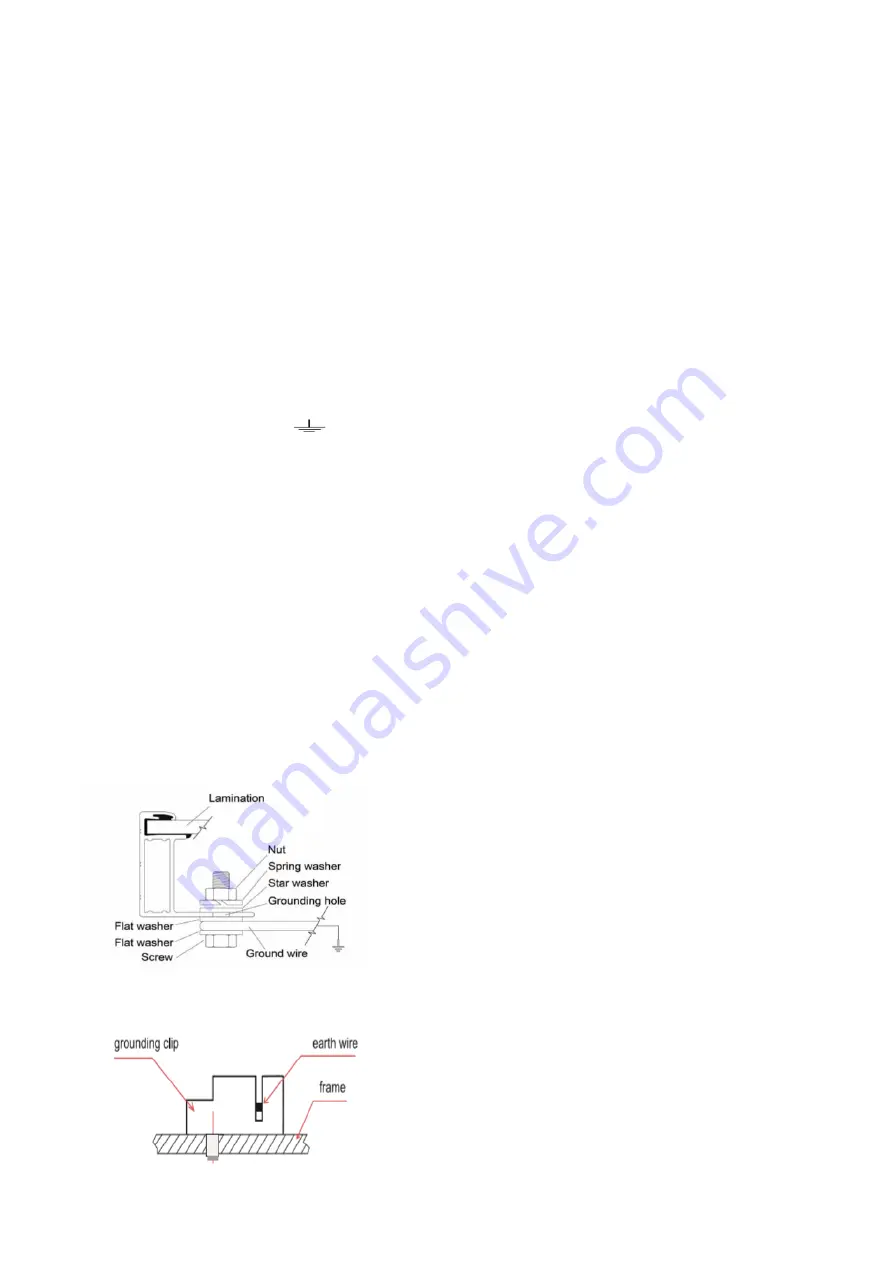

Grounding by grounding bolt

•

Use M8 bolt and washers to bond the ground wire and

aluminum frame through the grounding holes (as shown

figure 1

). The tightening torque is 3-7N.m. All nuts and

washers should be made of stainless steel.

figure 1

Grounding by using grounding clamp

figure 2

•

As shown in the

figure2

, the grounding clip assembly

consists of a slider, base, and self

–

captivating thread

–

cutting screw or 8

–

32 screw and hex nut. The grounding

clip accepts solid uninsulated copper wire sizes 10 or 12

AWG.

Addition Third-party Grounding Devices

•

DMEGC Solar

’s

Modules can be grounded using third

party grounding devices so long as they are certified for

grounding modules and the devices are installed

according to the manufacturer’s specified instructions.

6.

Mounting Instructions

The applicable regulations pertaining to work safety, accident

prevention and securing the construction site must be

observed. Workers and third party personnel shall wear or

install fall arrest equipment. Any third party need to be

protected against injuries and damages.

•

The mounting design must be certified by a registered

professional engineer. The mounting design and

procedures must comply with all applicable local codes

and requirements from all relevant authorities.

•

The module is considered to be in compliance with IEC

61730 and IEC 61215 only when the module is mounted

in the manner specified by the mounting instructions

included in this installation manual.

•

The system designer and installer are responsible for load

calculations and for proper design of support structure.

•

Any module without a frame (laminate) shall not be

considered to comply with the requirements of IEC 61730

unless the module is mounted with hardware that has

been tested and evaluated with the module under this

standard or by a field Inspection certifying that the

installed module complies with the requirements of IEC

61730.

•

DMEGC Solar does not provide mounting hardware.

•

Standard modules can be mounted onto a support

structure using one of several approved methods as

described below. For information about other installation

methods, please contact your local representative.

Failure to use a recognized installation method will void

the DMEGC Solar

’s

warranty.

•

Use appropriate corrosion-proof fastening materials. All

mounting hardware (bolts, spring washers, flat washers,

nuts) should be hot dip galvanized or stainless steel.