DMEGC Solar PV Modules Installation Manual

active components (such as inverter or combiner boxes)

before starting with the cleaning.

•

Wear suitable protection (clothes, insulated gloves, etc.).

•

Do not immerse the module, partially or totally, in water

or any other cleaning solution.

•

Rear side cleaning of the modules is not required. If

cleaning the rear of a module is desired, care should be

taken to ensure there is no damage caused to the

backsheet by simply clearing the contaminant by hand or

with a soft sponge.

Handing Notice

•

Use a proper cleaning solution and suitable cleaning

equipment.

•

Do not use abrasive or electric cleaners on the module.

•

Particular attention should be taken to avoid the module

backsheet or frame to come in contact with sharp objects,

as scratches may directly affect product safety.

•

Do not use abrasive cleaners, de-greasers or any

unauthorized chemical substance (e.g. oil, lubricant,

pesticide, etc.) on the module.

•

Do not use cleaning corrosive solutions containing

hydrofluoric acid, alkali, acetone, or industrial alcohol.

Only substances explicitly approved by DMEGC Solar are

allowed to be used for cleaning modules.

•

For cleaning methods using rotating brush, please

consult with DMEGC Solar's technical support before

using.

•

Dirt must never be scraped or rubbed away when dry, as

this will cause micro-scratches on the glass surface.

OPERATION PREPARATION

•

Noticeable dirt must be rubbed away by gentle cleaning

implement (soft cloth, sponge or brush with soft bristles).

•

Ensure that brushes or agitating tools are not abrasive to

glass, EPDM, silicone, aluminum, or steel.

•

Conduct the cleaning activities avoiding the hottest hours

of the day, in order to avoid thermal stress on the module.

CLEANING METHODS

Method A: Compressed Air

DMEGC Solar recommends cleaning the soft dirt (like dust)

on modules just with air pressure. This technique can be

applied as long as the method is efficient enough

considering the existing conditions.

Method B: Wet cleaning

•

If excessive soiling is present on the module surface, a

non-conductive brush, sponge, or other mild agitating

method may be used with caution.

•

Ensure that any brushes or agitating tools are

constructed with non-conductive materials to

minimize risk of electric shock and that they are not

abrasive to the glass or the aluminum frame.

•

If grease is present, an environmental-friendly cleaning

agent may be used with caution.

•

DMEGC Solar recommends the following to be used:

1. Water with low mineral content

2. Near neutral pH water

3. The maximum water pressure recommended is 4

MPa (40 bar)

Annex

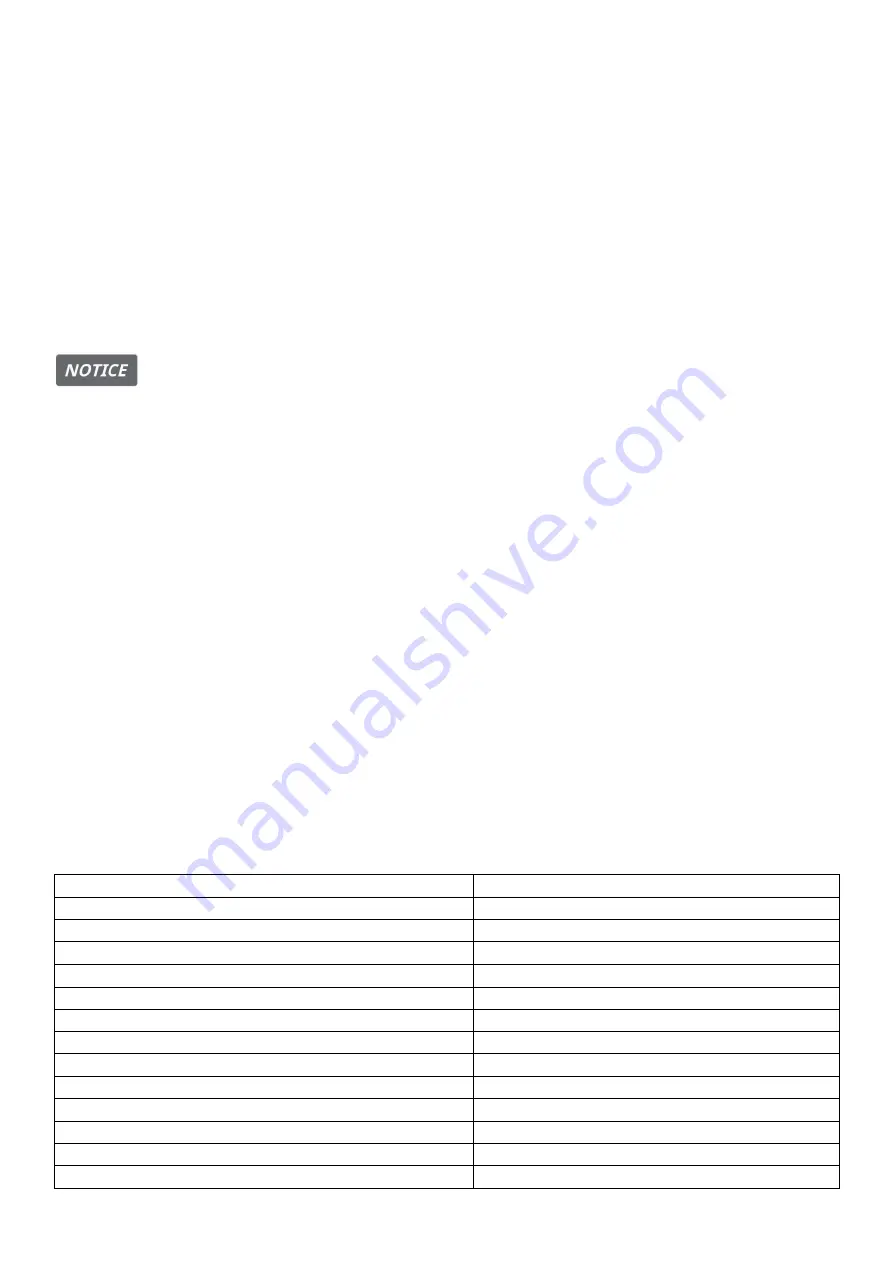

Glass/Foil Modules

Double Glass Modules

DMXXXM10-54HSW/HBW/HBB

DMXXXM10-G/B54HSW/HBW/HBB/HBT/HST

DMXXXM10-60HSW/HBW/HBB

DMXXXM10-G/B66HSW/HBW/HBB/HBT/HST

DMXXXM10-66HSW/HBW/HBB

DMXXXM10-G/B72HSW/HBW/HBB/HBT/HST

DMXXXM10-72HSW/HBW/HBB

DMXXXM10-G/B78HSW/HBW/HBB/HBT/HST

DMXXXM10-78HSW/HBW

DMXXXM6-G/B60HSW//HBW/HBB/HBT/HST

DMXXXM6-60HSW/HBW/HBB

DMXXXM6-G/B72HSW/HBW/HBB/HBT/HST

DMXXXM6-72HSW/HBW/HBB

DMXXXG1-G/B60HSW/HBW/HBB/HBT/HST

DMXXXG1-60HSW/HBW/HBB

DMXXXG1-G/B72HSW/HBW/HBB/HBT/HST

DMXXXG1-72HSW/HBW/HBB

DMXXXG1-G/B60SW/BW/BB/BT/ST

DMXXXG1-60SW/BW/BB

DMXXXG1-G/B72SW/BW/BB/BT/ST

DMXXXG1-72SW/BW/BB

DMXXXM2-G/B60HSW/HBW/HBB/HBT/HST

DMXXXM2-60HSW/HBW/HBB

DMXXXM2-G/B72HSW/HBW/HBB/HBT/HST

DMXXXM2-72HSW/HBW/HBB

DMXXXM2-G/B60SW/BW/BB/BT