Digital Monitoring Products

XR150/XR550 Series Canadian Installation Guide

10

INSTALLATION

Secondary Power Supply

6.1

Battery Terminals 3 and 4

Connect the black battery lead to the negative battery terminal. The negative terminal connects to the enclosure

ground internally through the XR150/XR550 Series circuit board. Connect the red battery lead to the battery positive

terminal. Observe polarity when connecting the battery.

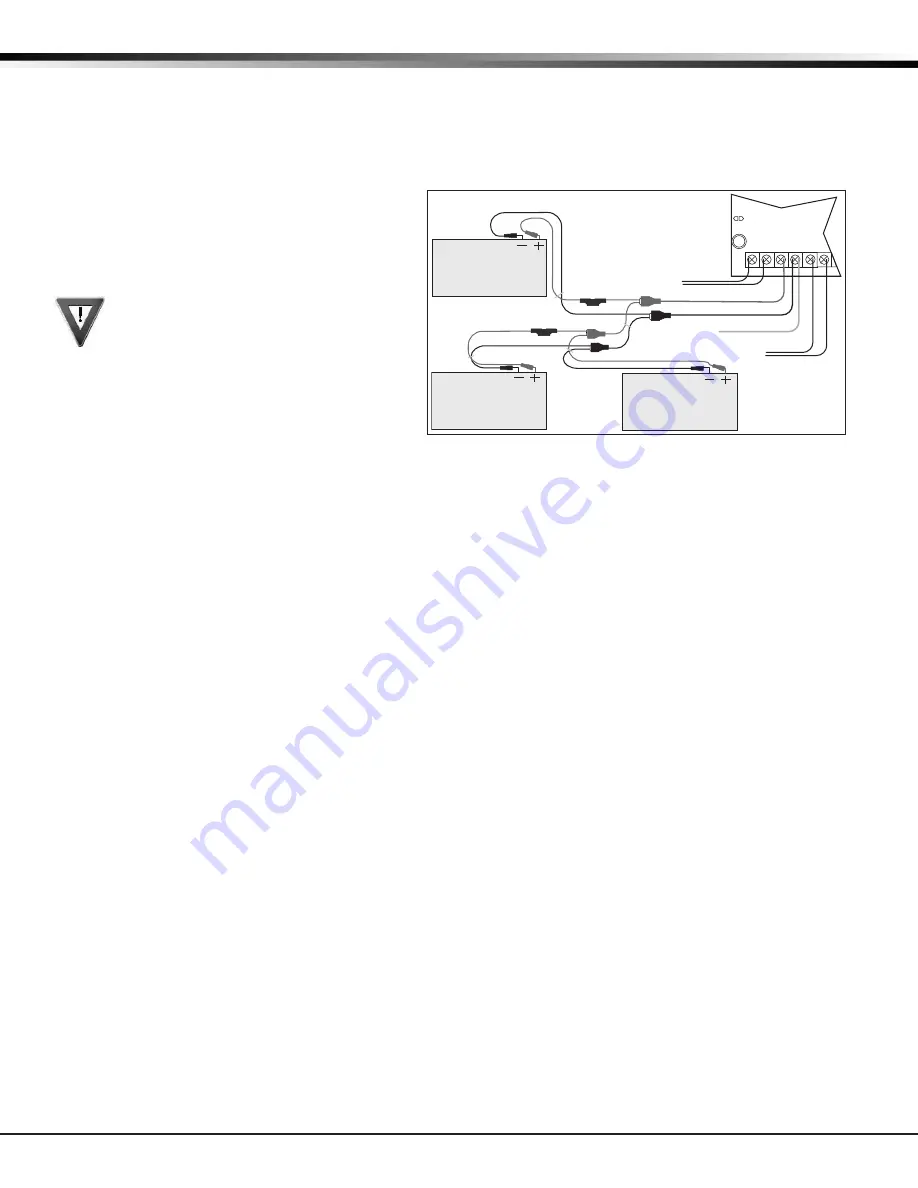

You can add a second battery in parallel using the DMP

Model 318 Dual Battery Harness.

DMP requires each

battery be separated by a PTC in the battery harness

wiring to protect each battery from a reversal or

short within the circuit. See Figure 6.

Use sealed lead-acid batteries only:

Use

the Model 365 (12VDC 9 Ah), Model 366

(12VDC 18 Ah), Model 368 (12VDC 5.0 Ah),

or Model 369 (12VDC 7 Ah) sealed lead-acid

rechargeable battery. Batteries supplied by

DMP have been tested to ensure proper

charging with DMP products.

GEL CELL BATTERIES CANNOT BE USED WITH THE

XR150/XR550 SERIES PANEL.

6.2

Earth Ground (GND)

To provide proper transient suppression, XR150/XR550 Series panel terminal 4 must be connected to earth ground

using 14 gauge or larger wire. DMP recommends connecting to a cold water pipe, ground rod, or building ground

only. Do not connect to an electrical ground or conduit, sprinkler or gas pipes, or to a telephone company ground.

6.3

Battery Only Restart

When powering up the XR150/XR550 Series panel without AC power, briefly short across the battery start pads to pull

in the battery cutoff relay. The leads need a momentary short only. Once the relay has pulled in, the battery voltage

holds it in that condition. If the XR150/XR550 Series panel is powered up with an AC transformer, the battery cutoff

relay is pulled in automatically. For more information refer to Figure 1.

6.4

Battery Replacement Period

DMP recommends replacing the battery every 3 to 5 years under normal use.

6.5 Discharge/Recharge

The XR150/XR550 Series battery charging circuit float charges at 13.8VDC at a maximum current of 1.0 Amps. Listed

below are the various battery voltage level conditions:

Battery Trouble: Below 11.9VDC

Battery Cutoff:

Below 10.2VDC

Battery Restored: Above 12.6VDC

6.6

Battery Supervision

The XR150/XR550 Series tests the battery when AC power is present. The test is done every three minutes and lasts

for five seconds. During the test, the panel places a load on the battery; if the battery voltage falls below 11.9VDC

a low battery is detected. If AC power is not present, a low battery is detected any time the battery voltage falls

below 11.9VDC.

If a low battery is detected with AC power present, the test repeats every two minutes until the battery charges

above 12.6VDC indicating the battery has restored voltage. If a weak battery is replaced with a fully charged

battery, the restored battery will not be detected until the next two minute test is completed.

6.7

Battery Cutoff

The panel disconnects the battery any time the battery voltage drops below 10.2VDC. This prevents battery deep

discharge damage.

AC

1

2

3

4

+B

AC

–B

Battery

Start

318 Battery

Harness

Panel Red and

Black Battery Cables

Red

Black

Battery

Battery

Battery

318 Battery

Harness

Red

Black

5

6

BELL GND

To AC

14 AWG to

Earth Ground

XR550

Panel

PTC

PTC

To Bell

Circuit

Figure 6: Wiring Multiple Batteries