1

MSEV Series and USHX Hardware Installation Manual Rev 1.7

1

Before You Begin

1.1

About This Manual

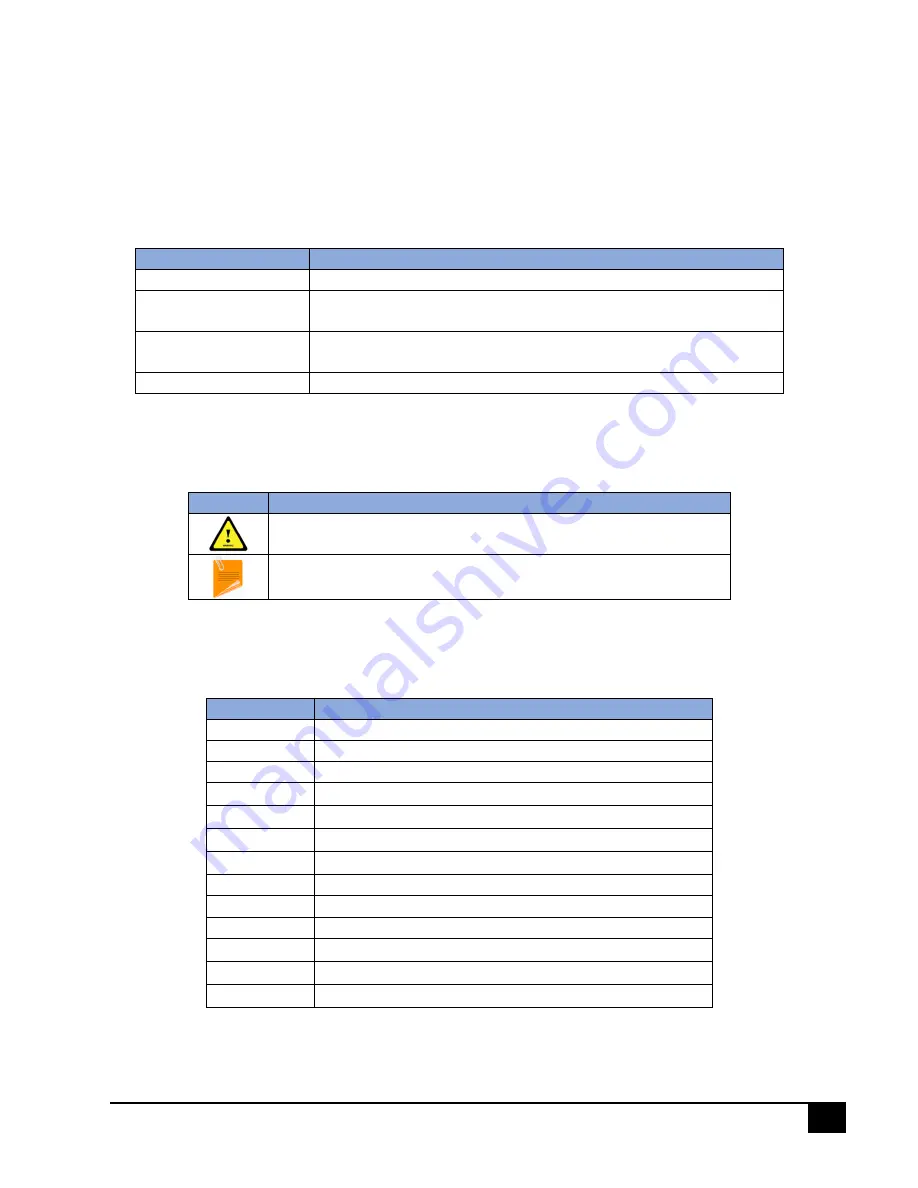

The following table shows a summary of the sections in this document and their descriptions.

Table 1-1 Descriptions of the Sections in the Document

Section Title

Description

Before You Begin

This section provides preliminary information about the products.

Mechanical Installation

This section provides instructions about the mechanical installation

of the MSEV series and the USHX in the system.

Electrical Wiring

This section provides instructions about the electrical wiring of the

MSEV series valve and the USHX.

Troubleshooting

This section provides solutions to potential problems.

1.2

Document Conventions

The following table shows a list of symbols found in this document and their descriptions.

Table 1-2 Descriptions of Symbols in the Document

Symbol

Description

WARNINGS indicate that the action you are taking could either

cause injury to yourself or could harm your products and systems.

IMPORTANT NOTES appear in the text to indicate additional

information that should be noted.

1.3

Acronyms

The following table shows a list of acronyms used in this document.

Table 1-3 Acronyms and Abbreviations in the Document

Acronym

Description

MSEV

Modular Silicon Expansion Valve

HC-MSEV

High Capacity Modular Silicon Expansion Valve

VHC-MSEV

Very High Capacity Modular Silicon Expansion Valve

MSEV Series

MSEV, HC-MSEV and VHC-MSEV

MEMS

Microelectromechanical Systems

EEV

Electronic Expansion Valve

TXV

Thermostatic Expansion Valve

HVAC/R

Heating, Ventilation, Air Conditioning, and Refrigeration

USHX

Universal SuperHeat Controller or Sensor

USHC

Universal SuperHeat Controller

USHS

Universal SuperHeat Sensor

ID / OD

Inner Diameter / Outer Diameter

AC / DC

Alternating Current / Direct Current