Dobinsons Springs and Suspension

22.

Align the bar with the vehicle into its correct

position, leaving an even gap between the top

of the bullbar and the bottom of the

flare/headlight/grill of about 10-20mm.

23.

Once you are happy with the alignment

tighten the nuts and bolts on each side.

24.

Tighten the adjustment stopped bolts so they

are firm against the front of the chassis.

25.

Using a 10mm drill bit, drill 10mm holes

through the bullbar mount into the mounting

bracket as seen below. This only drills through

the outer plate on the mounting face of the

mounting bracket.

26.

Install 10mm x 25mm high tensile bolts into

the pinning holes. Slide an 10mm nyloc nut

into the space between the 2 bracket plates

and align with the nut and tighten. This must

be done to prevent the bullbar moving when

winching.

27.

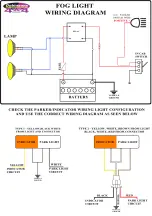

Plug the wires into the indicator, parker light

plug and fog lights. Test all lights and adjust

the position of the fog lights if required.

28.

Fit the under bar protection kit now with the

bolts supplied. The original plastic splash

guard can be secured to the rear of the new

bash plate.

29.

Trim the wheel arch mud guard liners back so

they are not visible from the front of the

vehicle.

30.

Check over all items removed during

installation.

31.

IMPORTANT NOTES: It is important to inform

the customer that headlight adjustment may

also be required due to the change in ride

height. It is also important to inform the

customer that there will be a change in

vehicle handling characteristics. It is also

important to note that due to their nature fog

lights are required to provide a yellow light to

allow clear fog vision. For this reason

Dobinsons bullbars utilise a Halogen bulb.

Halogen bulbs generate a considerable

amount of heat to achieve the yellow colour

and this causes the air inside the fog light lens

to expand and contract. For this reason the

fog light assembly cannot be sealed and has a

small breather on the back. In some cases this

may cause condensation to form inside the

fog light. The customer may choose to seal

the lens of the fog light but must not seal the

rear breather.