1

CAUTION: Do not scrape, rebabbitt, or otherwise alter

this product. Such action adversely affects bearing

performance and may result in damage or destruction

of equipment.

WARNING: Only qualified personnel familiar with the

construction and operation of this equipment and the

hazards involved should install, adjust, operate and/

or service it. Read and understand this manual in its

entirety before proceeding. Failure to observe this

precaution could result in severe bodily injury or loss

of life.

INSTALLATION:

The modular design of this bearing allows the use of multiple

types of liners and two or more bore sizes in the same housing.

Types of Liners

‘S’

— Standard liner (fixed or free) has symmetrical thrust faces

for bidirectional rotation.

‘T’

— High thrust, non-expansion (fixed) liner has tapered land

thrust faces which MUST be oriented with shaft rotation as

this type of thrust surface is unidirectional; Used with external

circulating oil lubrication only.

1. PRE-ASSEMBLY INSTRUCTIONS

Sleeve bearing performance is dependent on proper installation,

lubrication and maintenance. Before assembling the bearing,

read ALL instructions in this manual and follow all equipment

manufacturers’ instructions.

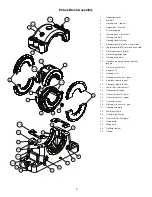

DODGE SLEEVOIL PILLOW BLOCK NAMEPLATE

All SLEEVOIL housings and liners have nameplates attached

to them. These nameplates have a six digit part number which

fully identifies the housing and/or liner with any and all factory

modifications to that part. Liner nameplate is pinned to the

SLEEVOIL upper liner near an oil ring inspection hole. Housing

nameplate is pinned to the housing foot parallel to the shaft.

WARNING: Because of the possible danger to person(s) or property from

accidents which may result from the improper use of products, it is

important that correct procedures be followed: Products must be used

in accordance with the engineering information specified in the catalog.

Proper installation, maintenance and operation procedures must be

observed. The instructions in the instruction manuals must be followed.

Inspections should be made as necessary to assure safe operation under

prevailing conditions. Proper guards and other suitable safety devices or

procedures as may be desirable or as may be specified in safety codes

should be provided, and are neither provided by Dodge nor are the

responsibility of Dodge. This unit and its associated equipment must be

installed, adjusted and maintained by qualified personnel who are familiar

with the construction and operation of all equipment in the system and

the potential hazards involved. When risk to persons or property may be

involved, a failsafe device must be an integral part of the driven equipment

beyond the speed reducer output shaft.

Instruction Manual for

DODGE SLEEVOIL RXT

®

Pillow Blocks

With Self Lubrication (oil ring)

These instructions must be read thoroughly before installation or operation.

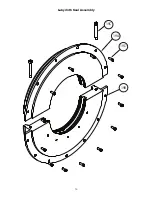

DODGE SLEEVOIL PILLOW BLOCK “MATCH

MARKS”

HSG MATCH MARKS

LINER MATCH MARKS

All SLEEVOIL housing and liner halves have match marks

permanently stamped above and below the joint. Use these match

marks to ensure that parts stay paired and critical machined areas

of an assembly are accurately maintained.

NOTE: Refer to applicable contract/assembly drawings to

verify all parts are available prior to assembly.

Disassemble and thoroughly clean all parts of the pillow block.

The installer is the last person to inspect all parts for fit, damage

and cleanliness. Care MUST be taken to avoid contaminating

the internal surfaces of the bearing. Housing caps and bases are

match marked and MUST NOT be interchanged. Upper and lower

liners are also match marked and MUST NOT be interchanged

NOTE: DO NOT DISCARD SHIMS AT JOINT. THEY ARE USED

LATER FOR A CONTROLLED INTERFERENCE FIT OF LINER

IN HOUSING. (See page 4)

CAUTION: Liner assembly has critical machined surfaces

which are easily damaged. Use care when handling to protect

these surfaces. Liner parts should be placed on a soft, CLEAN

surface. Failure to observe these precautions may result in

damage to or destruction of the equipment.

WARNING: Rust preventives and solvents can be toxic and/

or flammable. Follow directions and safety procedures

recommended by their manufacturers. Failure to observe

these precautions could result in bodily injury.

Check the mounting structure to ensure it is rigid, leveled, and

well supported. Inspect the shaft to ensure it is smooth (32 rms

or 0.8 microns finish or better), free of burrs or rough spots and

clean. Position the housing base on the pedestal in the position

specified on the construction drawing. Do NOT tighten the base

to the pedestal.