1

WARNING: To ensure the drive is not unexpectedly started, turn off and lock-out or tag power source before proceeding.

Failure to observe these precautions could result in bodily injury.

WARNING: All products over 25 kg (55 lbs) are noted on the shipping package. Proper lifting practices are required for

these products.

WARNING: Because of the possible danger to person(s) or property from accidents which may result from the improper use

of products, it is important that correct procedures be followed. Products must be used in accordance with the engineering

information specified in the catalog. Proper installation, maintenance and operation procedures must be observed. The

instructions in the instruction manuals must be followed. Inspections should be made as necessary to assure safe operation

under prevailing conditions. Proper guards and other suitable safety devices or procedures as may be desirable or as may

be specified in safety codes should be provided, and are neither provided by Dodge nor are the responsibility of Dodge.

This unit and its associated equipment must be installed, adjusted and maintained by qualified personnel who are familiar

with the construction and operation of all equipment in the system and the potential hazards involved. When risk to persons

or property may be involved, a holding device must be an integral part of the driven equipment beyond the speed reducer

output shaft.

TXT/ABHS Reducer Harsh Duty Covers

Installation Instruction Manual

These instructions must be read thoroughly before installation or operation. This instruction manual was accurate at the time of

printing. Please see

dodgeindustrial.com

for updated instruction manuals.

Auxiliary Output Covers Installation

TXT/ABHS1 and TXT/ABHS2:

1. Using the one piece auxiliary cover (supplied in kit) as a

template, drill two #17 diameter holes 7/16” deep in face of

left (input side) housing.

2. Using the two piece auxiliary cover (supplied in kit) as a

template, drill four #17 diameter holes 7/16” deep in face of

right (backstop side) housing.

3. Install auxiliary covers using screws (self-tapping) supplied

in kit.

NOTE: Before drilling holes, mask or tape off seal area to

prevent cast iron shaving from damaging seals.

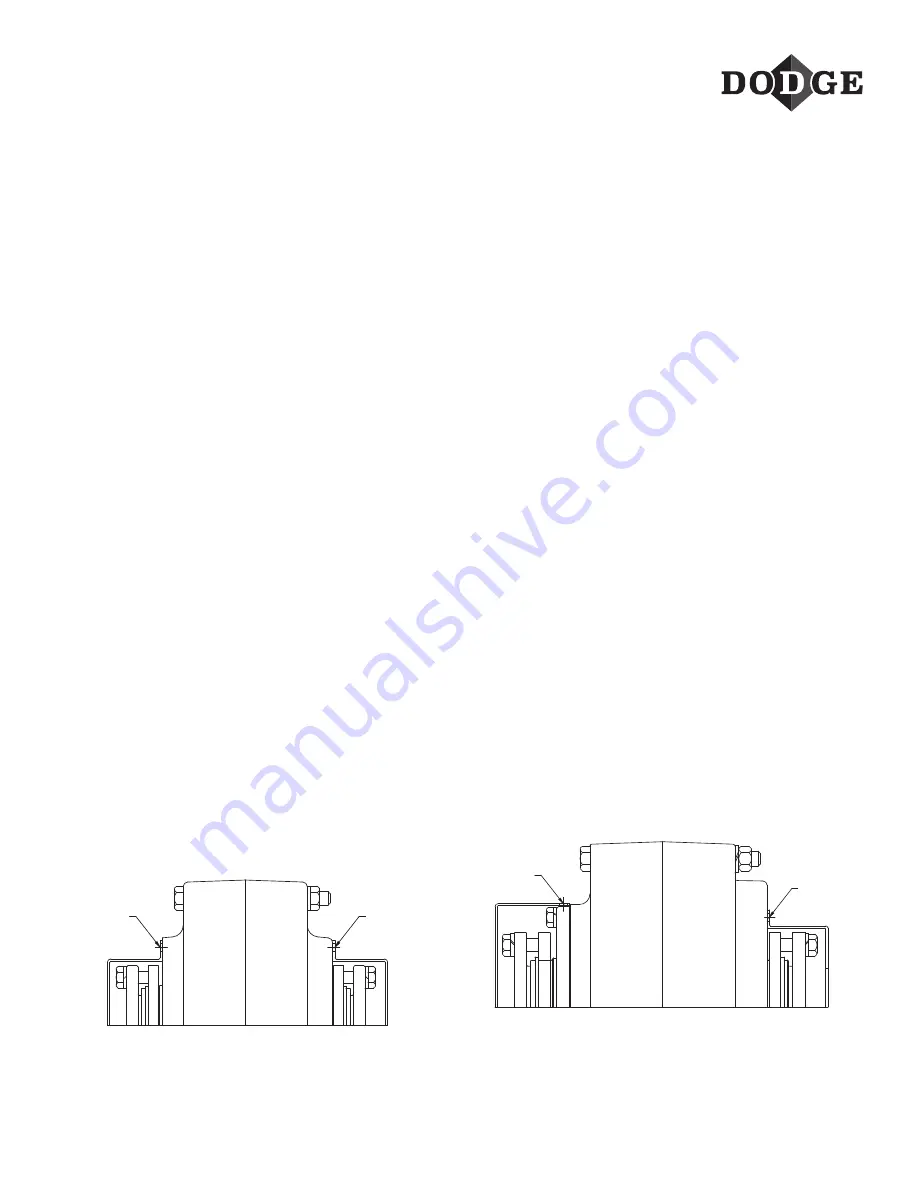

TXT1ABHS THRU TXT2ABHS

DRILL HERE

DRILL HERE

TXT/ABHS3 thru TXT/ABHS5:

1. Using the one piece auxiliary cover (supplied in kit) as a

template, drill two #17 diameter holes 7/16” deep in output

seal carrier on left (input) side of reducer.

2. Using the two piece auxiliary cover (supplied in kit) as a

template, drill four #17 diameter holes 7/16” deep in face of

right (backstop side) housing.

3. Install auxiliary covers using screws (self-tapping) supplied

in kit.

Note: Before drilling holes, mask or tape off seal area to

prevent cast iron shaving from damaging seals.

TXT3ABHS THRU TXT5ABHS

DRILL HERE

DRILL HERE