22

999775002 - 02/2020

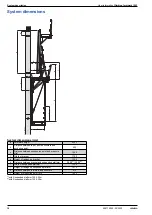

Anchoring on the structure

User Information

Climbing formwork 150F

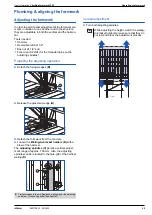

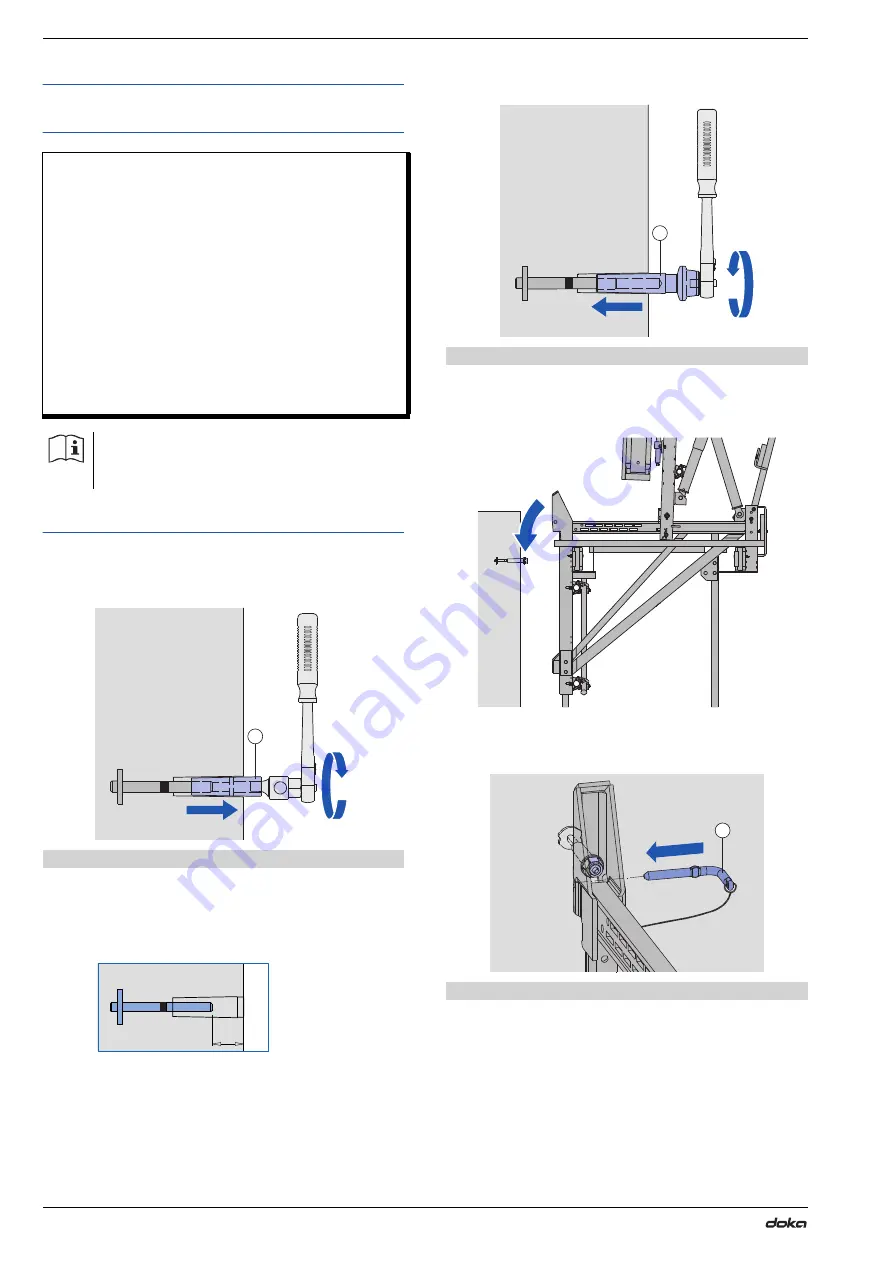

Preparing the suspension point

Dimensioning the suspension point

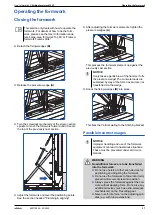

Engaging the climbing bracket

➤

Unscrew the positioning cone, using a Reversible

ratchet 1/2" and a Positioning-cone spanner 15.0

DK.

Check of the positioning point

➤

Check the code on the stop anchor.

➤

Check the placement depth of the stop anchor.

a ... placement depth: 50 mm

➤

Screw in the climbing cone until this is fully engaged,

and tighten it with a Reversible ratchet 1/2".

➤

Suspend the climbing formwork from the climbing

cones.

➤

Insert the fastening pin with its handle in the horizon-

tal

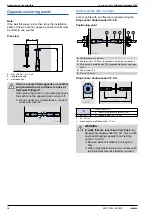

The required

cube compressive strength

of the con-

crete at the time of loading must be

specified

sepa-

rately for each project

by the structural designer

. It

will depend on the following factors:

▪

load actually occurring

▪

length of stop anchor or pigtail anchor

▪

reinforcement / extra reinforcement steel

▪

distance from edge

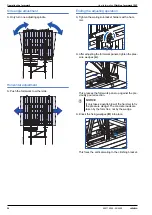

The introduction of the forces, the transfer of these

forces into the structure, and the stability of the overall

construction, must all be verified by the structural

designer.

The required cube compressive strength f

ck,cube,current

must be at least 10 N/mm

2

, however.

Follow the directions in the Calculation Guide

entitled "Load-bearing capacity of anchorages

in concrete" or ask your Doka technician!

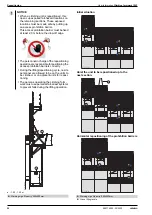

A

Positioning cone 15.0 5cm

9775-226-02

A

9 -

775 269-21

a

B

Climbing cone 15.0 5cm

C

Fastening pin

9775-228-01

B

9775-229-01

9775-230-01

C

Summary of Contents for 150F

Page 2: ...2 999775002 02 2020 User Information Climbing formwork 150F ...

Page 26: ...26 999775002 02 2020 Anchoring on the structure User Information Climbing formwork 150F ...

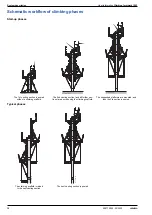

Page 34: ...34 999775002 02 2020 Repositioning User Information Climbing formwork 150F ...

Page 52: ...52 999775002 02 2020 Assembly User Information Climbing formwork 150F ...