User Information

Climbing formwork 150F

Repositioning

31

999775002 - 02/2020

Repositioning

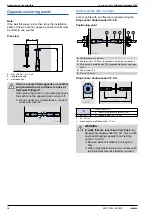

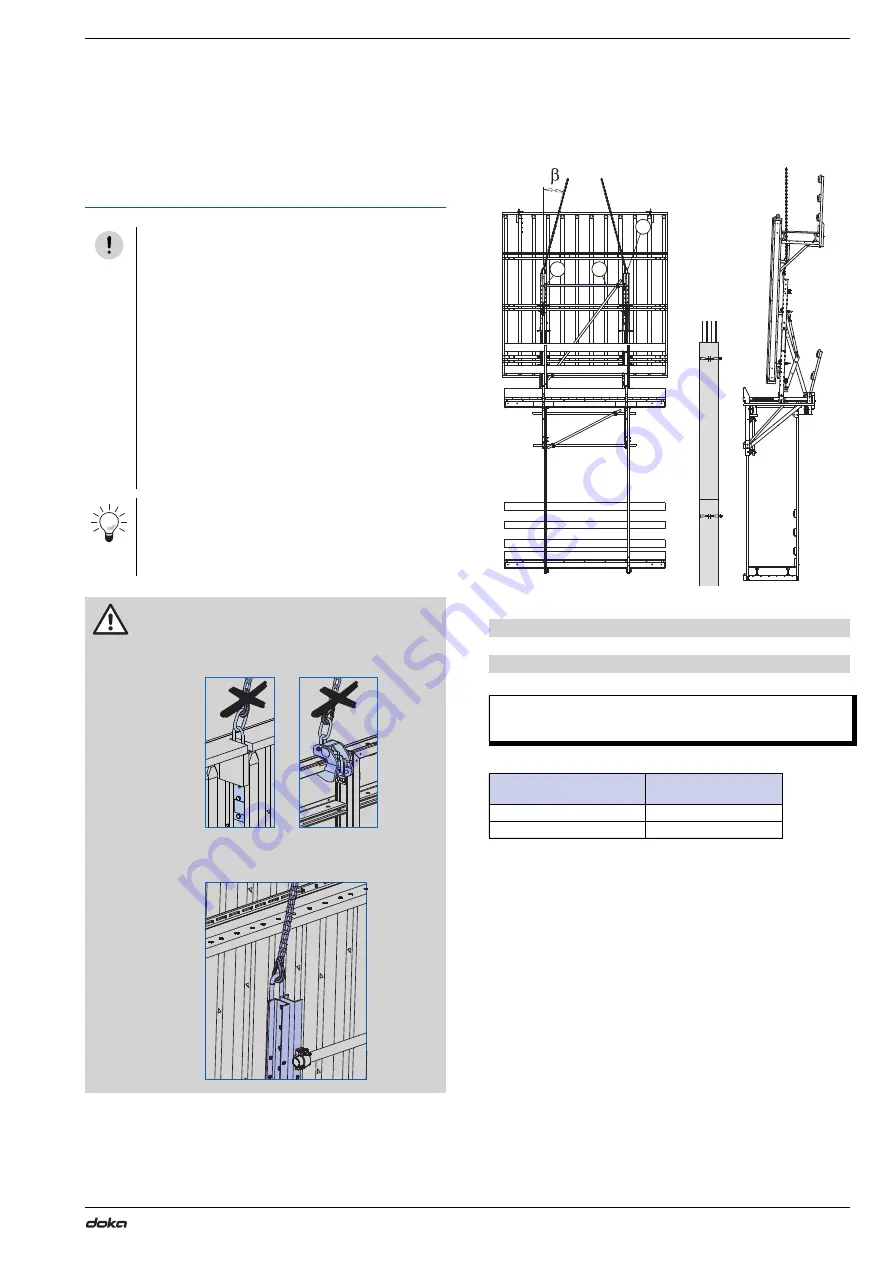

Lifting by crane

Instructions for safe repositioning of

the complete unit

The suspension methods shown above are only

needed for assembling and dismantling the formwork

panels.

β

... max. 30°

Required number of braces against oblique pull:

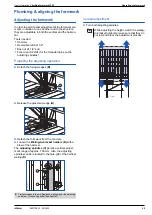

NOTICE

▪

Before repositioning:

Remove any loose

items from the formwork and platforms, or

secure them firmly.

▪

'Passenger transportation' is forbidden!

▪

Observe all regulations applying to the

operation of cranes where higher wind

speeds are experienced.

▪

Spread angle

β

: max. 30°

▪

Brace the vertical waling sufficiently

against oblique pull.

Tightening torque of couplers: 50

Nm

▪

When using lifting beams, ensure that these

have sufficient load-bearing capacity!

Length of chain

= at least the space between

the hoisting points

This automatically leads to the required

spread angle

β

.

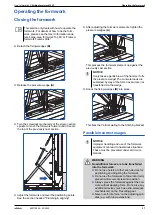

WARNING

➤

Any

lifting brackets

on the formwork pan-

els, or

Framax lifting hooks

, must

not

be

used for lifting the unit as a whole.

➤

Attach the lifting chains to the lifting brackets

of the vertical waling.

9715-268-01

9775-281-01

9775-247-02

A

Lifting bracket of the vertical waling

B

Bracing against oblique pull (e.g. scaffold tube)

C

Screw-on coupler

Max. load-bearing capacity:

3500

kg per lifting bracket of the vertical waling

Total weight

of unit to be lifted

Number of braces

(e.g. scaffold tubes)

up to 2000

kg

1

up to 3500

kg

2

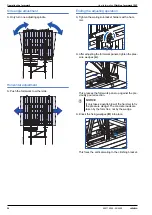

9775-247-01

B

A

C

9775-246-01

Summary of Contents for 150F

Page 2: ...2 999775002 02 2020 User Information Climbing formwork 150F ...

Page 26: ...26 999775002 02 2020 Anchoring on the structure User Information Climbing formwork 150F ...

Page 34: ...34 999775002 02 2020 Repositioning User Information Climbing formwork 150F ...

Page 52: ...52 999775002 02 2020 Assembly User Information Climbing formwork 150F ...