14

999803902 - 06/2014

Structural design

User Information

Dokaflex

30

tec

Structural design

Simple structural design

The spacings of the beams and floor props can be opti-

mised using the technical slide-rule.

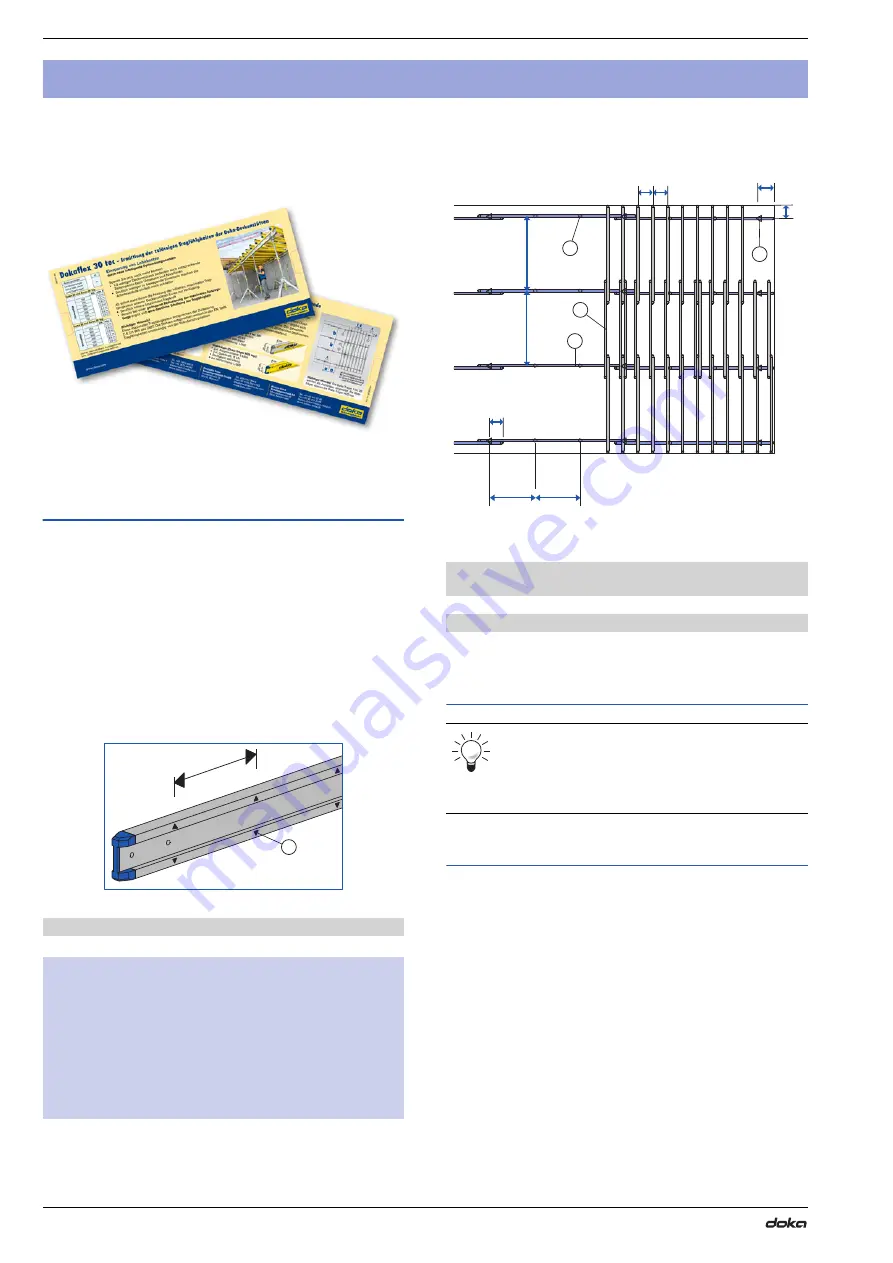

Spacing and positions of the

component parts

Equipment usage can be fully optimised (see the sec-

tion headed "Optimising the structural design with

regard to equipment quantities").

An even more methodical and faster way of erecting

the formwork is to site-specifically base the spacings on

the 0.5

m grid shown by the spacing marks on the

beams.

You can tell at a glance whether the formwork has been

erected correctly, and without having to measure up.

For examples of site-specific grids, see the "Practical

examples".

x ... 0.5 m

a ... spacing of props

b ... spacing of primary beams

c ... spacing of secondary beams, and distance from edge

Primary and secondary beams

Format of the formwork sheets

The ProFrame panels, in formats of

200x50cm

and

250x50cm

(21 or 27mm), have just the right dimen-

sions to fit exactly into the increment-grid of the Doka-

flex system.

Structural design

A

Mark

1 mark = 0.5

m

2 marks = 1.0

m

2

1

/

2

marks = 1.25

m

3 marks = 1.5

m

3

1

/

2

marks = 1.75

m

4 marks = 2.0

m

x

9768-202-01

A

A

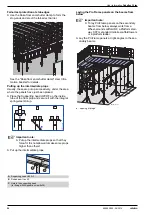

"Main prop" (floor prop + Lowering head H20 + removable fold-

ing tripod)

B

"Intermediate prop" (floor prop + Supporting head H20

DF)

C

Doka beam H20 top (secondary beam)

D

Doka beam I

tec

20 (primary beam)

The primary beams should be orientated at

right angles to the direction of an uneven

length/width of room (5

m,

7 m,

9 m,

etc.).

This

makes more efficient use of the potential of the

system.

a a

b

b

c c

c

c

c

98039-202-01

A

B

C

D