User Information

Framed formwork Framax Xlife plus

Wall formwork

61

999811202 - 04/2019

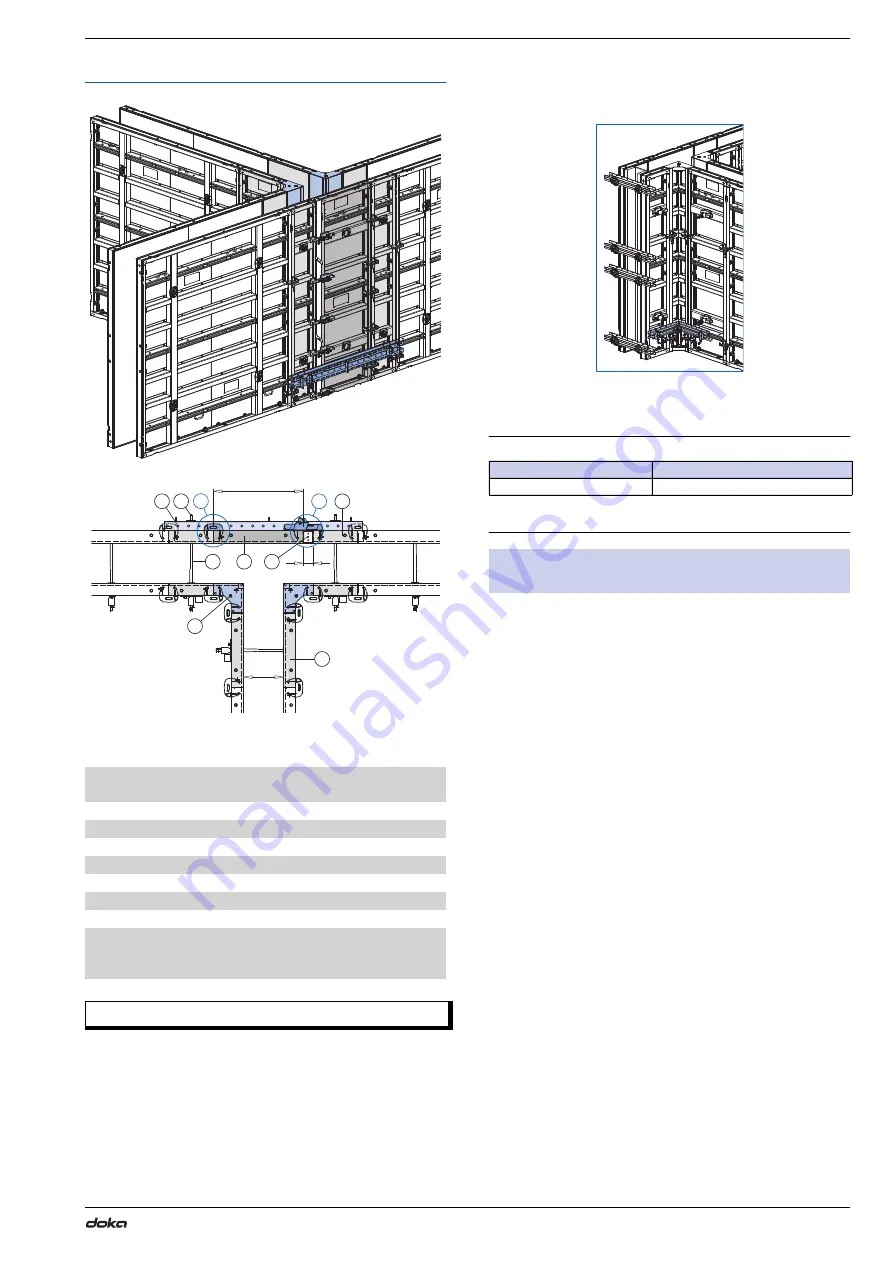

Wall thickness up to 40

cm

a ... Wall thickness (max. 40

cm)

b ... Panel width

c ... Closure width

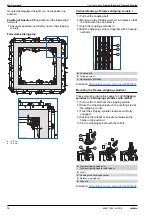

Note:

If the wall sections are short

it is advisable to brace

the inside corner with a

universal corner waling

.

Width of the Framax Xlife plus panel in the straight

wall

Closure width in the straight wall

Example:

▪

Wall thickness = 40

cm

=> Panel width (b) =

90

cm (0.90m)

Closure width = 60

cm - 90

cm - 40

cm =

10

cm

A

Framax Xlife plus inside corner 30/30cm or

Framax Xlife inside corner

B

Framax Xlife plus panel

0.90m

C

Framax Xlife plus panel

(max. width of 0.30m)

D

Framax Xlife plus panel

(max. width of 0.90m)

E

Closure

0 - 15 cm

(Framax alu closure / Framax fitting timber)

G

Tie rod system Framax Xlife plus 20.0

H

Multi-purpose waling WS10

Top50

I

Framax wedge clamp

J

Inter-panel connection (see the section headed 'T-junction:

Inter-panel connections on Framax Xlife plus panels in the

straight wall')

Permitted fresh-concrete pressure:

60kN/m²

9 - -018112

344

a

b

c

9 - -0

8112 344 2

A

B

E

D

G

J

J

C

H

I

Wall thickness (

a

)

Panel width (

b

)

>30 - 40

cm

0.90m (90

cm)

Closure width

c

=

60

cm + wall thickness

a

[cm] - panel width

b

[cm]

98112 346

- -01

Summary of Contents for Framed formwork Framax Xlife plus

Page 2: ...2 999811202 04 2019 User Information Framed formwork Framax Xlife plus ...

Page 51: ...User Information Framed formwork Framax Xlife plus Wall formwork 51 999811202 04 2019 ...

Page 70: ...70 999811202 04 2019 Wall formwork User Information Framed formwork Framax Xlife plus ...

Page 117: ...User Information Framed formwork Framax Xlife plus Wall formwork 117 999811202 04 2019 ...

Page 127: ...User Information Framed formwork Framax Xlife plus General remarks 127 999811202 04 2019 ...

Page 139: ...User Information Framed formwork Framax Xlife plus Component overview 139 999811202 04 2019 ...