User Information

Ringlock

Ringlock Overview

15

999817902 - 10/2022

Instructions for Scaffolding Construction

Thanks to the flexibility of the wedge connection, the

Ringlock modular scaffolding system can be used for

everything from simple façade scaffolding to complex

industrial support scaffolding. The relevant characteris-

tic values such as stiffness and load-bearing capacity

of the scaffolding system can be found in the approval

certificate Z-8.22-992.

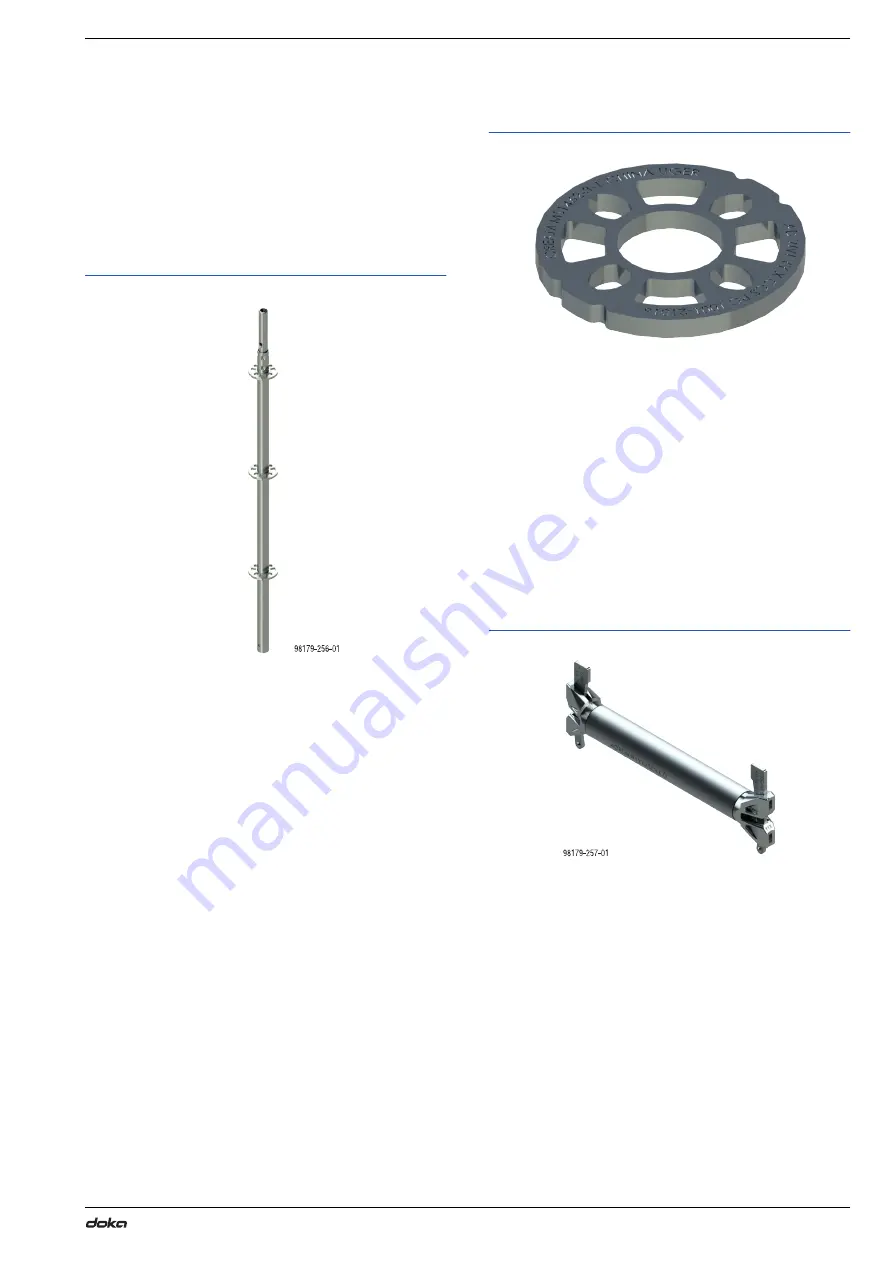

Vertical Standard

The robust Ringlock is made of high-quality steel. For

maximum flexibility, rosettes are welded to the vertical

standards at 50 cm intervals, to which up to 8 compo-

nents can be connected using the widely used and

proven wedge connection.

Ringlock rosette

▪

Each rosette has eight openings. The smaller open-

ings are generally used to help guide the scaffolding

to make 90 degree connections, whereas the larger

opening enable connections at variable angles to be

achieved.

▪

Unless erecting a scaffold around a circular building

structure, align the Base Collar rosettes so that one

of the small openings in the rosette points in the

Ledger direction. The small openings at right angles

to the first will automatically align the Transoms at 90

degrees.

▪

The larger openings are generally used for connect-

ing the diagonal braces.

Ringlock Ledger

The ledgers can be easily installed by sliding the tran-

som head onto the rosette and then wedging it in place.

The wedges are permanently connected to the ledger

and, as an assembly aid, allow a rigid connection to be

made even when the wedge is only loosely inserted.

Before the components are loaded, the tight fit between

the wedge and the rosette or vertical stem must be

achieved with a 500g hammer until impact is felt. The

disassembly of the ledgers is done in reverse order:

The wedge is loosened by hitting it from below with a

hammer and pulled out of the rosette by hand.

98179-202-01