44

999817902 - 10/2022

Scaffold

User Information

Ringlock

Suspended Scaffolding

The purpose of suspended scaffold is to optimize the

amount of material at extreme height or when a sup-

ported scaffold is not possible.

Method of Scaffolding Suspension

There are different methods of suspending scaffolds

from permanent structure, which includes both not lim-

ited to the following:

Methods of scaffold suspensions can utilize the Rin-

glock components with the combination of tube and

couplers, and/or chain/wire rope.

▪

Beam Clamps may be used to attach the Standard to

the permanent steel beam at the bottom or top beam

flange. When attaching the Standard to the steel

beam, the suspension point may be on one side or

both sides of the steel beam.

▪

Box tie arrangement may be used to attach the per-

manent beam by utilizing tubes and couplers all

around the existing structure.

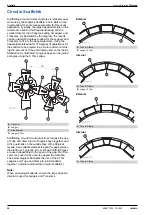

Detail 1: Girder Coupler Arrangement

Note:

Typical Suspension Load with Girder Coupler Arrange-

ment.

Detail 2: Suspended around Beam

Note:

Typical Total Suspension Load with Box Tie.

A

Standard

B

D/F Right Angle Coupler (Supplementary Couplers as required)

C

Suspension Tube no more than 0.3m from I-Beam

D

I-Beam

E

Girder Coupler (used in pairs)

F

Scaffold Tube

A

Standard

B

Suspension no more than 0.3m from I-Beam

C

If lower loads are required a typical short Scaffold Tube can be

used instead of a Ringlock Standard

D

I-Beam

E

D/F Right Angle Coupler

F

Scaffold Tube