User Information

Ringlock

Scaffold

53

999817902 - 10/2022

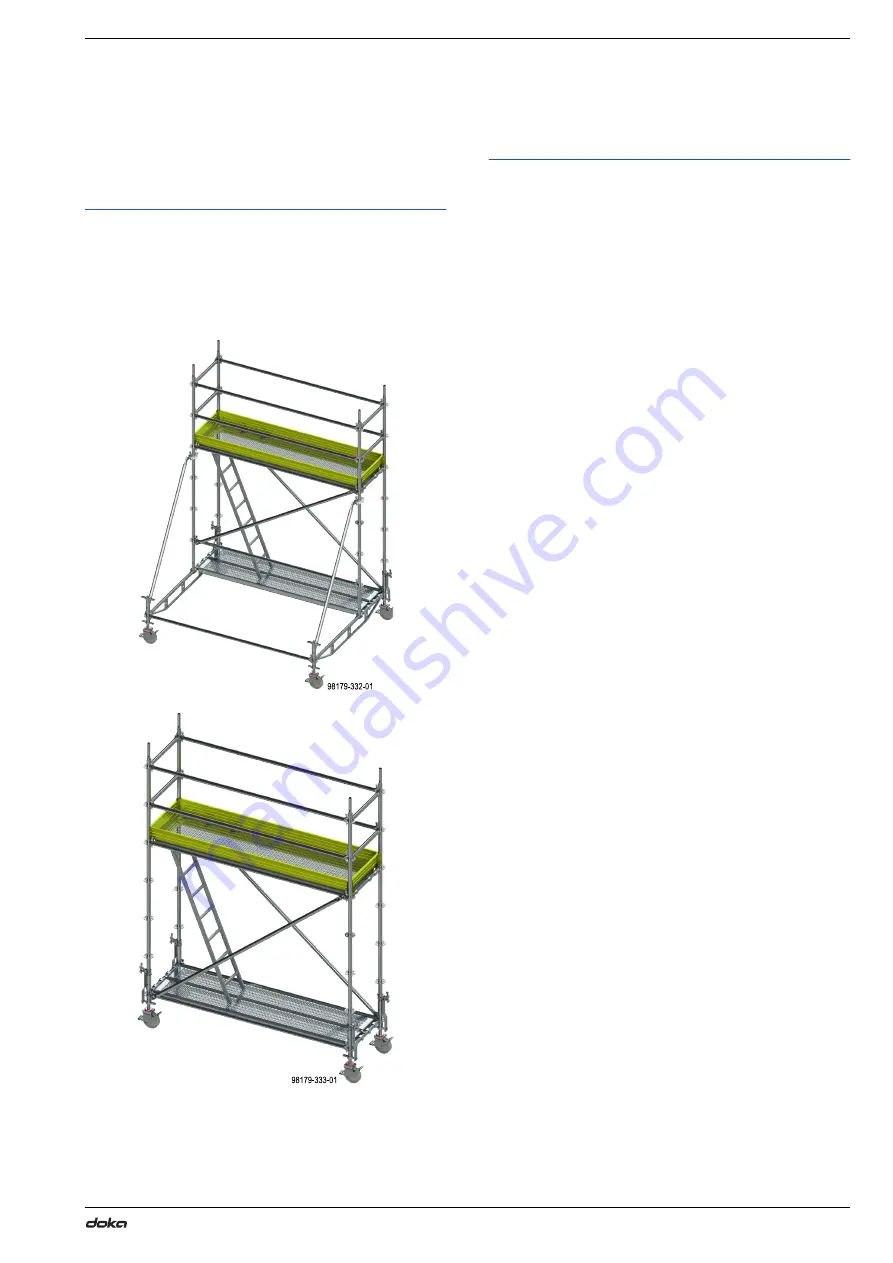

Mobile Scaffolds

The purpose of rolling scaffolds is to access large areas

with the minimum amount of material on a flat/level sur-

face.

Types of Rolling Scaffolds

Depending on the site condition, required height, and

material availability, there are different types of rolling

scaffolds. To achieve lateral stability , outrigger (but-

tress) bay and / or ballast should be used.The outrigger

width and ballast weight must be calculated to ensure

the required regulations are met.

Note:

Ballast may be required per Stability Analysis.

Safty Guidelines for Erection for

Rolling Scaffolds

The following precautions apply to the erection of roll-

ing scaffolds:

▪

The height of the rolling scaffold must not be greater

than 2 times its minimum base dimension (length or

width), measured at the base of the tower unless it is

equipped with engineered guy wires or outriggers.

▪

lf outriggers are used to stabilize a rolling scaffold

with a height that is greater than 2 times the mini-

mum base dimension (length or width), the minimum

width is measured between outriggers.Outriggers,

additional bays, or other means may be added to the

bottom of a scaffold structure to increase the mini-

mum base dimension of the scaffold. The resulting

modified base dimension may no longer be the min-

imum (or limiting) base dimension when calculating

the 'height-to-base ratio' of the scaffold structure.

▪

When a rolling scaffold is in proximity to energized

electrical equipment, the wheels must be fitted with

nonconductive resilient tires. Always lockout and

tagout all electrical hazards.

▪

Fit each wheel or Caster on a mobile scaffold with

brakes or other locking devices to prevent rolling and

swiveling when the scaffold is in use.The Casters

must be securely attached to the scaffold.

▪

lf Base Jacks are used to increase the height of the

tower, they must not be extended by more than 12"

(0.3m).The tower must be kept plumb and level at all

times.

▪

Use plan-bracing at the top and bottom of rolling tow-

ers where the top platform is more than 9'-0" (2.7 m)

above the supporting surface. When towers are to be

erected higher than 9-0" (2.7 m), the first brace must

be no more than 2'-0" (0.6 m) above the Casters and

subsequent plan-braces above must be installed at

no more than 13' (4.0 m) intervals.

▪

Use steel Planks or decking units with hooks or

cleated Wood Planks on rolling scaffolds.

▪

Apply horizontal force as close to the base as possi-

ble when moving the tower.

▪

Workers should never stand on, or work from a Roll-

ing Tower when it is being moved.

▪

Max. vertical distance between working platform is

4.0 m unless plan braces are installed according to

the previous rules.

▪

Diagonal braces required on all four sides of the roll-

ing scaffold tower.

▪

As per EN

1004 maximum height of the rolling scaf-

fold tower indoor is 12 m and outdoor 8 m.However

static calculation against tilting is required in every

case.

▪

When ballast is required, the ballast weight must be

verified and installed correctly as per Cantilever Sec-

tion.