User Information

Ringlock

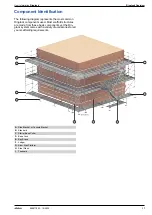

Introduction

9

999817902 - 10/2022

Quality Factors & Designation

Quality Factors

All of Doka Ringlock products are engineered to meet

the highest quality standards based on three simple

factors:

▪

Material

We only use the highest quality steel in our products.

Our steel is certified and tested, it conforms to or

exceeds industry standards no matter the location or

climate.

▪

Fit

Doka products are engineered with versatility and

usability in mind. Our modified product designs

increase efficiencies and productivity, saving your

projects time and money.

▪

Finish

Where applicable, our products are finished and pro-

tected by hot-dipped zinc galvanizing. This method

of finishing maximizes the utilization and extends the

product life.

For additional information on Ringlock system compo-

nents please consult your local Doka representative.

Designation

The Designation of Ringlock in accordance with

EN

12810-1:2003

is:

Scaffold EN

12810 - 3D - SW06/307 - H2 - B - LS

Service Load Class 3 may be extended from Service

Load Class 1 to Service Load Class 6 if required

although there are restriction on bay length for Service

Load Classes 5 and 6. This User Information only con-

siders Service Load Class 1 to Class 3 as the general

loading required of a system scaffold under normal cir-

cumstances.

Service Load Class 3: The following combinations of

platform width and bay length are also available:

SW06/73 to SW06/307

CLADDING:

Maximum permissible heights and tie pat-

terns are given for both unsheeted, debris netted and

sheeted scaffolds.

For more information on products not found within this

document or the Ringlock Brochure please consult your

local Doka representative, or online at www.doka.com.

Node capacities 1.65 Safety Factor

The Ringlock modular scaffold system may be used as

a work and protective scaffold according to EN

12811

with load class 3. The system dimensions of the stand-

ard design are bay length L

≤

3.072m and bay width b

= 0.732m. The maximum height of the top scaffold layer

is 24m plus the spindle extension. If the actions on the

framework from the traffic load do not exceed the ser-

vice value of the loads specified in EN

12811,

Table

3,

the standard design can be used without further verifi-

cation. According to EN

12810, the following designa-

tion must be used for the standard designation of the

Ringlock scaffold system as a facade scaffold:

Scaffolding EN

12810-3D-SW06/307-H2-A-LS

All the decks of the Ringlock modular scaffold system

can be used as overhead protection. The following

information provides an overview of the most important

characteristic valuesof the Ringlock modular scaffold

and is taken from the general building approval / gen-

eral type approval Z-8.22-992.

The Ringlock modular framework node has the follow-

ing design values of stresses (

γ

F

= 1.5;

γ

M, steel

= 1.1):

N

Rd

= ± 36.8 kNm)

M

x,Rd

= ± 58.5 kNcm)

V

z,Rd

= ± 27.3 kN)

M

y,Rd+

= ± 132 kNcm

M

y,Rd-

= ± 121 kNcm

V

y,Rd

= ± 11.1 kN

M

x,Rd

= ± 45.3 kNcm)