User Information

Load-bearing tower Staxo

100

eco

Repositioning

37

999808702 - 11/2019

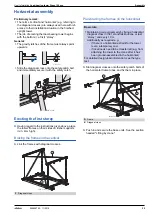

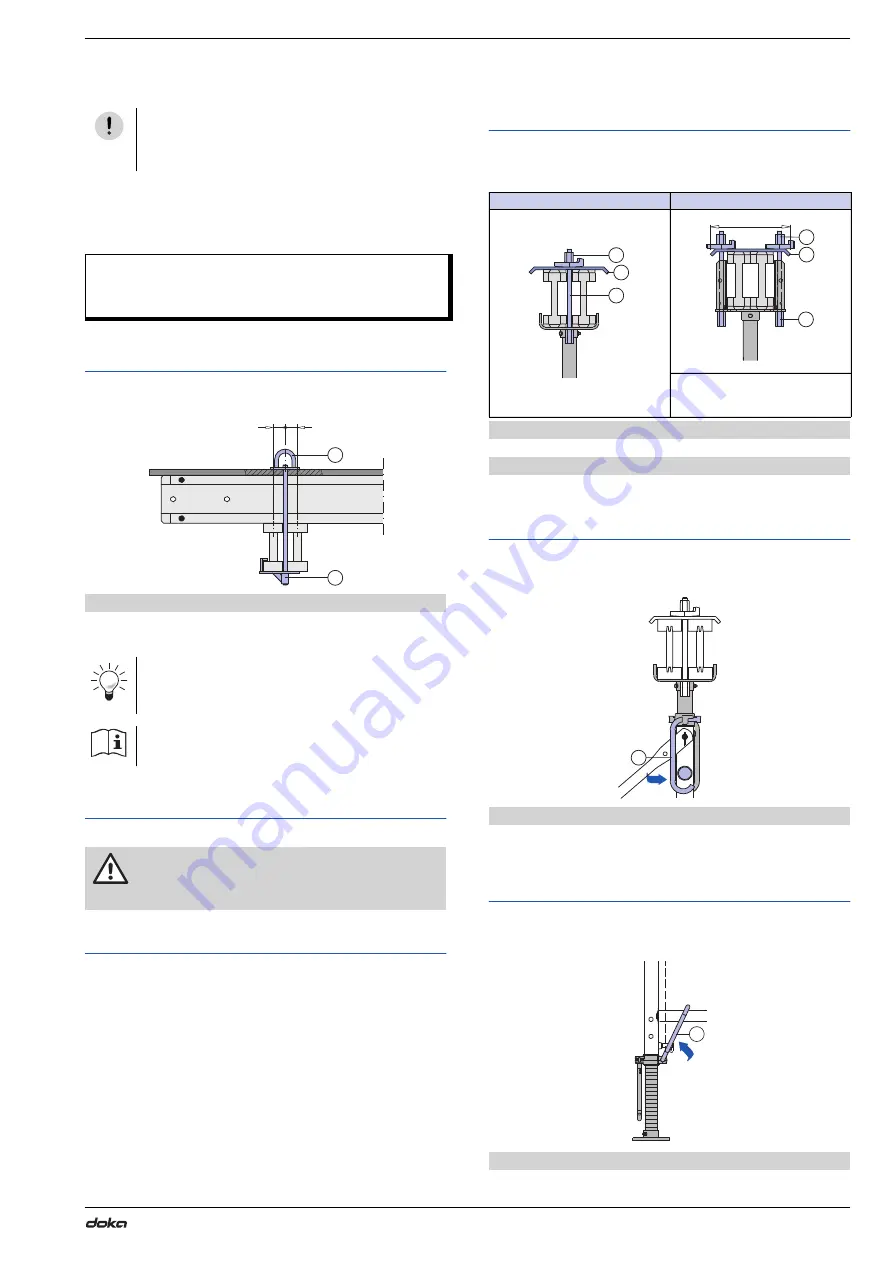

Lifting by crane

Where the tableforms are to be repositioned in the ver-

tical, i.e. crane-lifted, they must be fitted with a

Lifting

rod 15.0

and

Retaining plate 15.0

, which make it easy

to attach the transfer cables.

Assembly

➤

Mount the Lifting rod 15.0 and Retaining plate 15.0.

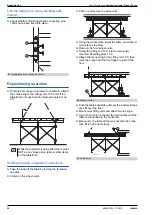

Preparation

Connect superstructure components together

➤

e.g. connect the primary and secondary beams to

rafter plates, and nail on the form-ply.

Connect the superstructure to the head units

➤

e.g. with Locking rod 15.0, Clamping plate and Wing

nut 15.0.

Secure the head units so that they cannot be

lifted out

➤

Slot the fixing handle into the cross-tube of the

frame.

Secure the base units to prevent them

dropping out

➤

Slot the fixing handle into the cross-tube of the

frame.

NOTICE

The max. height of towerframe unit that can be

lifted in one piece is 20

m!

Max. load:

1000

kg per Lifting rod 15.0 - where the load is applied

centrally

A

Lifting rod 15.0

B

Retaining plate 15.0

Use a 20

mm diam. bit to drill the hole through

the form-ply. It can later be filled with a Univer-

sal plug R20/25.

Follow the directions in the Operating Instruc-

tions!

WARNING

Danger from loose and unsecured parts.

➤

Observe the following points before lifting!

9720-276-01

5.1

5.1

A

B

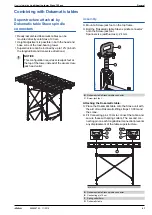

On Screw jack U-head

On 4-way screw-jack head

Only possible with Clamping

plate a = 28

cm (2002 models

onward)

D

Locking rod 15.0

E

Clamping plate

F

Wing nut 15.0

G

Fixing handle

I

Fixing handle

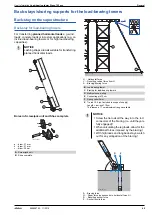

9734-236-02

D

E

F

9734-277-01

D

E

F

a

9716-285-01

G

98087-213-03

I