52

999808702 - 11/2019

General

User Information

Load-bearing tower Staxo

100

eco

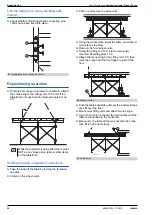

Inclination adjustment

If the superstructure or the ground are

inclined at an

angle of 1% or more

, slope compensation must be

provided.

using Wedges for screw-jack

.....

%

These prefabricated birch plywood wedges make it

possible to stand load-bearing towers in the perpendic-

ular on surfaces with various inclinations, even when

utilising the full leg load.

Inclined superstructures

Securing the superstructure at angles greater than

12%:

➤

Connect the head-plate to the longitudinal beam

(e.g. with Locking rod 15.0 330mm and Super plate

15.0 or Angle anchor plate 12/18)

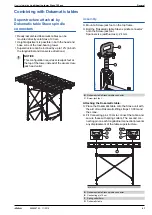

Inclined ground surface

using Staxo wedge support WS10

Used with timber wedges, this component provides

angle adjustment to floor-slab constructions with a

max. inclination of 45°.

Bolted into the multipurpose waling, this wedge support

prevents the timber wedges slipping and ensures that

the loads are safely transferred.

Note:

If the legs of the load-bearing tower have to be located

outside the pattern of drilled holes in the multi-purpose

waling, then a suitable 20

mm diam. hole must be

drilled in the web of the waling.

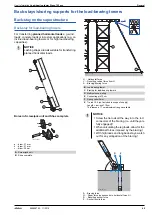

using Staxo wedge support WU12/14

Same function as Staxo wedge support WS10, except

that it is suitable for being pinned to a 12

cm or 14

cm

high waling.

The wedge support is labelled '12' and '14' on the

respective sides, to ensure that it is always correctly

positioned.

CAUTION

Excessively steep wedges may slip away!

➤

Maximum inclination: 20%!

For this reason, wedges must NOT be placed

on top of one another in an attempt to compen-

sate for inclinations that are greater than 20%.

A

Wedge for screw-jack

.....

%

B

Locking rod 15.0 330mm

C

Super plate 15.0

D

Wedge for screw-jack

.....

%

9703-255-01

A

B

C

D

9703-254-01

NOTICE

This type of connection is no substitute for

extra structural design measures such as

back-stays.

View without superstructure

a ... min. 15

cm

A

Staxo wedge support WS10

B

Timber wedge, project-specific

C

Multi-purpose waling WS10 Top50

D

Nailed connection

NOTICE

The grain of the timber wedges must always

be in the vertical!