40

999804302 - 02/2018

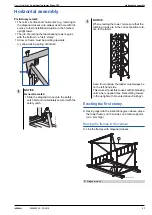

Assembling towers in the upright

User Information

Load-bearing tower Staxo 100

Head zone

Fitting the head unit

➤

Press the blue locking springs of the top frames

towards the inside (to open them).

➤

Insert the head unit.

Always place the primary beams (single or double

formwork beams) centrally.

The screw jack U-heads can also be turned to an angle

to keep single formwork beams centred.

Dismantling

After the tower has been placed back on its side, it can

be dismantled in reverse order.

I

Blue locking spring

J

Head unit

98003-212-02

I

J

9716-215-01

WARNING

➤

Where formwork beams cantilever out a long

way, secure them against accidental lift-out.

WARNING

Loads that are applied non-centrally can cause

overloading of the system.

➤

Ensure that all loads are applied centrally!

NOTICE

➤

When lifting and repositioning the entire

tower unit (or pre-assembled sub-units) by

crane: Follow the instructions in the section

headed 'Lifting by crane'!

NOTICE

As early as in the planning phase, considera-

tion should also be given to the dismantling

operations (e.g. travelling/towing the load-

bearing tower/unit into the reach of the crane

for safe repositioning or for horizontal on-

ground dismantling)!

9776-102-01