Summary of Contents for Opticooler

Page 1: ...TEMPERATURE THAT ARRIVES Opticooler Quick User Guide ...

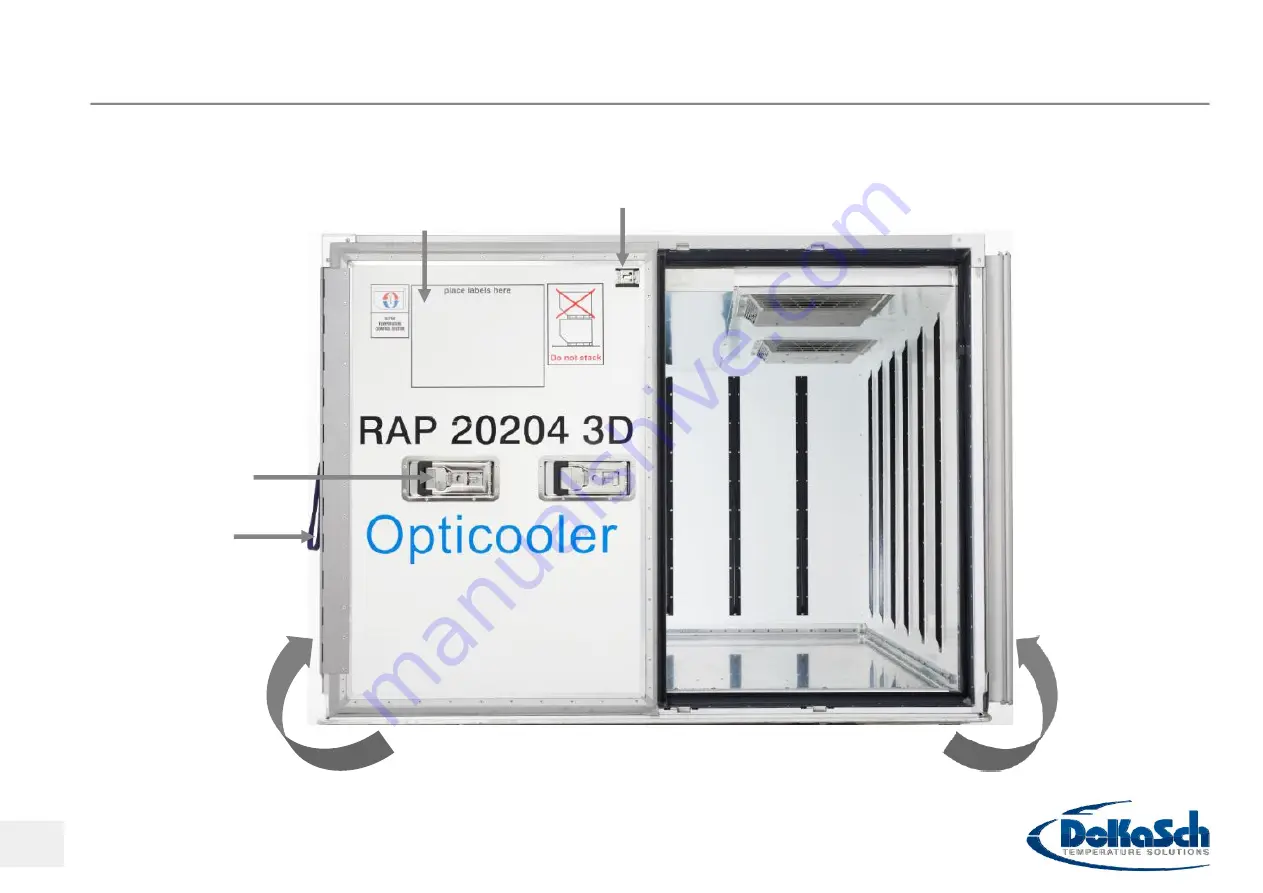

Page 20: ...20 RAP Details ...

Page 22: ...RAP Front view space for labels 22 270 door opening hand strap door handle door locker ...

Page 23: ...RAP Front view 23 270 door opening ...

Page 25: ...25 RKN Details ...