2

07.10.15 en / 477

Notes

•

Settings to the unit must be performed by skilled personnel while

the unit is disconnected.

•

Before the front cover is removed, antistatic precautions must be

observed.

Automatic Start

Automatic start is only performed when the supply voltage is switched on

or when the Emergency stop or stop function has been reset (with switch

positions 7 to 9, also after undervoltage).

All other errors nevertheless require confirmation by a start input.

Manual Start

Stop

Instead of the fourth start button, an additional stop input (NC contact)

can be connected. It is assigned only to the control unit and treated like an

additional single-channel emergency stop button.

This means that the safety outputs assigned to the control unit can only be

activated if neither the emergency stop or the stop button are activated.

Green LEDs (left):

on, when all inputs are present and start

button activated.

Green LEDs (right):

on, when the safety outputs of the

control unit are activated.

White LEDs Run 1 and

Run 2 and semiconduc-

tor outputs 48 and 58: Indicate the current status of the

control unit.

Indication

If operating function 2, 6 or 7 is selected, an assignment to the start

input 4 will remain ineffective in all connected modules.

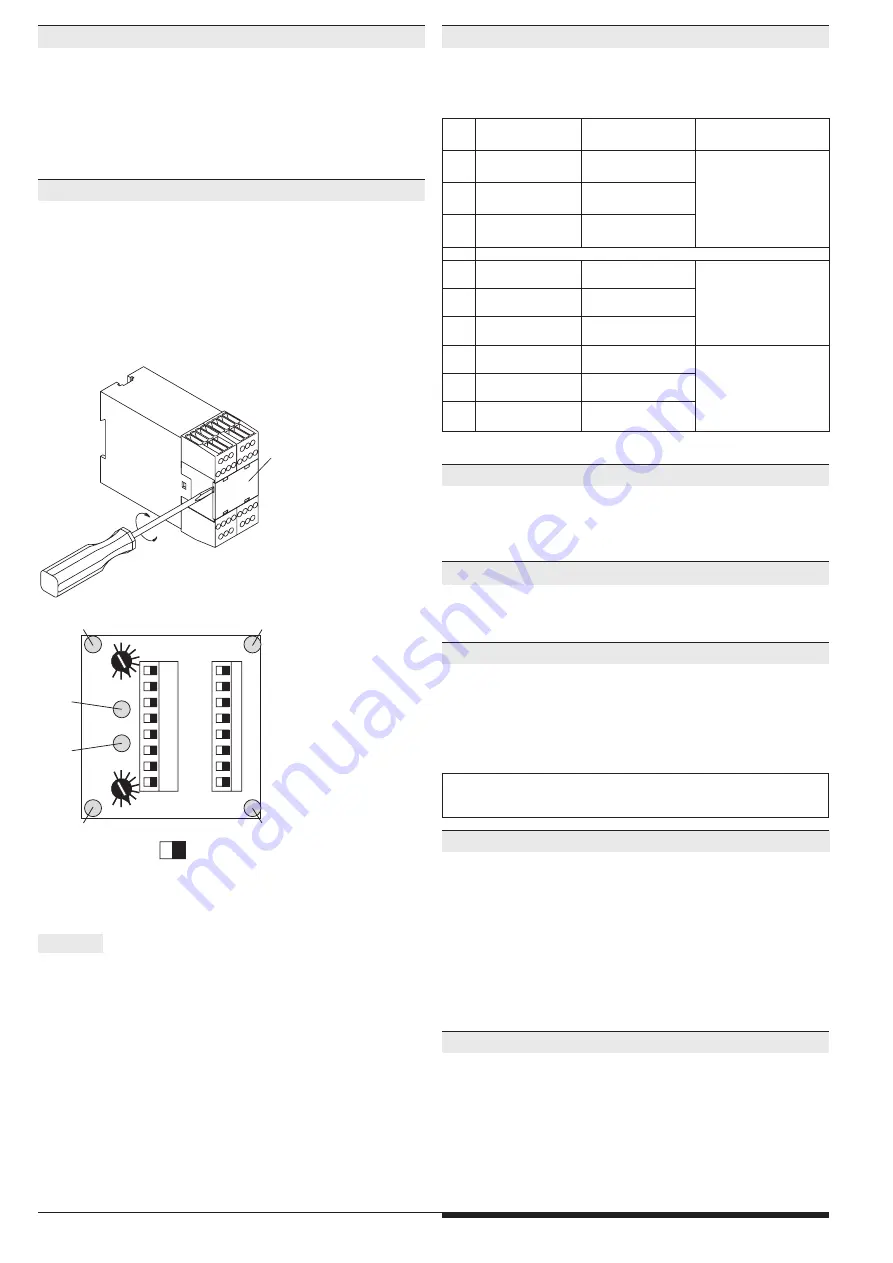

Setting of Functions

The control unit is assigned to the start inputs T1…T4 and the safety out-

puts via the DIP switches. The input function is set by means of the rotary

switches. To prevent accidently adjustments the setting switches are covered

by a front plate and are redundant.

The control unit is supplied with two fitted terminating connectors. When the

control unit is equipped with extension modules, remove these ter -minating

connectors and plug them to the last interconnected device. When a diagnostic

module is used, it is connected instead of the terminating con -nector.

The start input must not be pressed for more than 3 seconds to start the sy-

stem. Alternatively, several start inputs may be assigned to one module.

plate

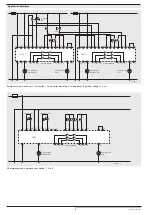

M2929

M9039_

b

0

0 1

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

2

2

3

4 output

start input

Mod3

T1

Mod2

T2

Mod1

T3

Base

T4

Mod3

T1

Mod2

T2

Mod1

T3

Base

T4

5

6

7

7

8

white LED

"run 1"

white LED

"run 2"

S1

S2

green LED "K1"

green LED "en 1"

green LED "en 2"

9

9

green LED "K2"

off

on

Lock-Out after Undervoltage

When an undervoltage is detected, the whole system (including any ex-

tension modules) turns off (auto reset). There are two different options of

auto restart:

1. The system de-energises the safety outputs as soon as undervoltage

has been detected.

There after the system will only reset after complete removal of voltage.

2. The system de-energises the safety outputs and remains de-energized

until supply voltage is back to a permissible value. Then, the system is

restarted.

Shortcircuit and Crossfault Detection

The control unit has an integrated dynamic shortcircuit and crossfault

detection. This feature can only be used when the inputs are switched by

contacts and if they are only connected to one safemaster input.

To connect light curtains of type 4 or to operate several safemaster M

units from common sensors a special wiring has to be chosen.

Notes:

•

Settings to the unit must be performed by skilled personnel while the

unit is disconnected.

•

Before the front cover is removed, antistatic precautions must be

observed.

base = Output of control Unit

mod = Output of output module

Sw

Function

Start input selection

Start function s

etting conditions

0

1 E-stop or 1 LC*

2 channel

4 start inputs

Automatic start

lock-out following

undervoltage

1

2 E-stop

1 channel

4 start inputs

2

1 E-stop or 1 LC*

2 channel

3 start inputs

1 Stop

3

not permitted (error 5)

4

1 E-stop or 1 LC*

2 channel

4 start inputs

Manual start

5

2 E-stop

1 channel

4 start inputs

6

1 E-stop or 1 LC*

2 channel

3 start inputs

1 Stop

7

1 E-stop or 1 LC*

2 channel

3 start inputs

1 Stop

Automatic start

following undervoltage,

restart after the voltage

has returned to the

permissible value

8

1 E-stop or 1 LC*

2 channel

4 start inputs

9

2 E-stop

1 channel

4 start inputs

* LC = light curtain