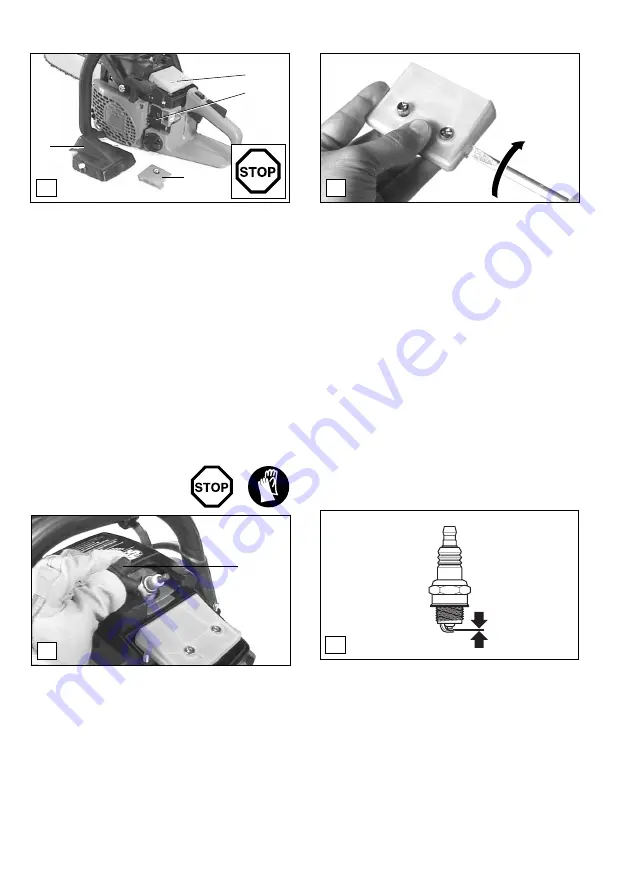

20

Electrode gap

The electrode gap must be 0.5 mm.

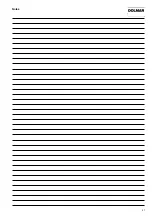

Checking the ignition spark

- Press the loosened spark plug with the ignition cable

Þ

rmly

connected against the cylinder using insulated pliers (not

near the spark plug opening).

- ON/OFF switch in the "

I

" (ON) position.

- Pull the starter cable hard.

If the function is correct, an ignition spark must be visible near

the electrodes.

CAUTION:

Do not touch the spark plug or plug cap if the engine is

running (high voltage).

Switch off the engine before starting any maintenance work.

A hot engine can cause burns. Wear protective gloves!

The spark plug must be replaced in case of damage to the

insulator, electrode erosion (burn) or if the electrodes are very

dirty or oily.

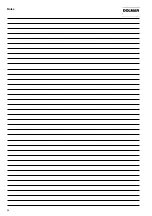

- Remove

the

Þ

lter cover (see "Cleaning the air

Þ

lter").

- Pull the plug cap (

G/1

) off the spark plug. Use only the

combination wrench supplied with the saw to remove the

spark plug.

CAUTION:

Use only the following spark plugs:

BOSCH WSR 6F

or

NGK BPMR 7A

.

Replacing the spark plug

Cleaning the air

Þ

lter

F

G

1

- Remove

the

Þ

lter cover (

E/1

) (2 screws).

- Loosen the screws on the air

Þ

lter (

E/2

) and remove from

intake manifold.

- Loosen the screw on the pre

Þ

lter cover (

E/3

) and remove.

- Remove

pre

Þ

lter (

E/4

).

IMPORTANT:

Cover the intake opening with a clean cloth to prevent dirt

particles from getting into the carburetor.

- Pry apart the top and bottom of the air

Þ

lter as shown in

Figure F.

CAUTION:

To prevent injury to the eyes, do NOT blow out dirt particles!

Do not use fuel to clean the air

Þ

lter and pre

Þ

lter

.

E

2

4

1

3

- Clean the air

Þ

lter and pre

Þ

lter with a soft brush.

- If

the

Þ

lter is very dirty, clean it in lukewarm water with dish-

washing detergent.

- Let the air

Þ

lter

dry completely

.

- Put the top and bottom sections back together.

-

Before reinstalling the air

Þ

lter, check the intake opening and

remove any dirt particles. If there are any, remove them with

a brush.

Clean frequently (several times a day) when working in very

dusty or dirty conditions. Full engine power is possible only with

a clean air

Þ

lter and pre

Þ

lter!

Important:

For sawing dry wood and working on dusty ground

we recommend using a

Robko

ß

ok air

Þ

lter

(available as an

accessory). The Robko

ß

ok

Þ

lter keeps out even the smallest

dust particles.

CAUTION:

If the air

Þ

lter or pre

Þ

lter becomes damaged,

replace immediately!

Pieces of cloth or large dirt particles can destroy the en-

gine!

H

0,5 mm