80

81

Remove the old locking

cylinder if necessary (not il-

lustrated).

Carefully remove Pro cylin-

der with pre-assembled

outside knob from the

packaging.

Align the cam flush with the

cylinder body.

Carefully slide Pro cylinder

through the fitting.

Hold authorised transpon-

der in front of the knob if

necessary, in order to enga-

ge the cam and align the Pro

cylinder.

Fix the Pro cylinder with the

screw as soon as you feel

the correct position.

Check that the knob turns

freely without scraping on

the fitting.

Tighten the screw.

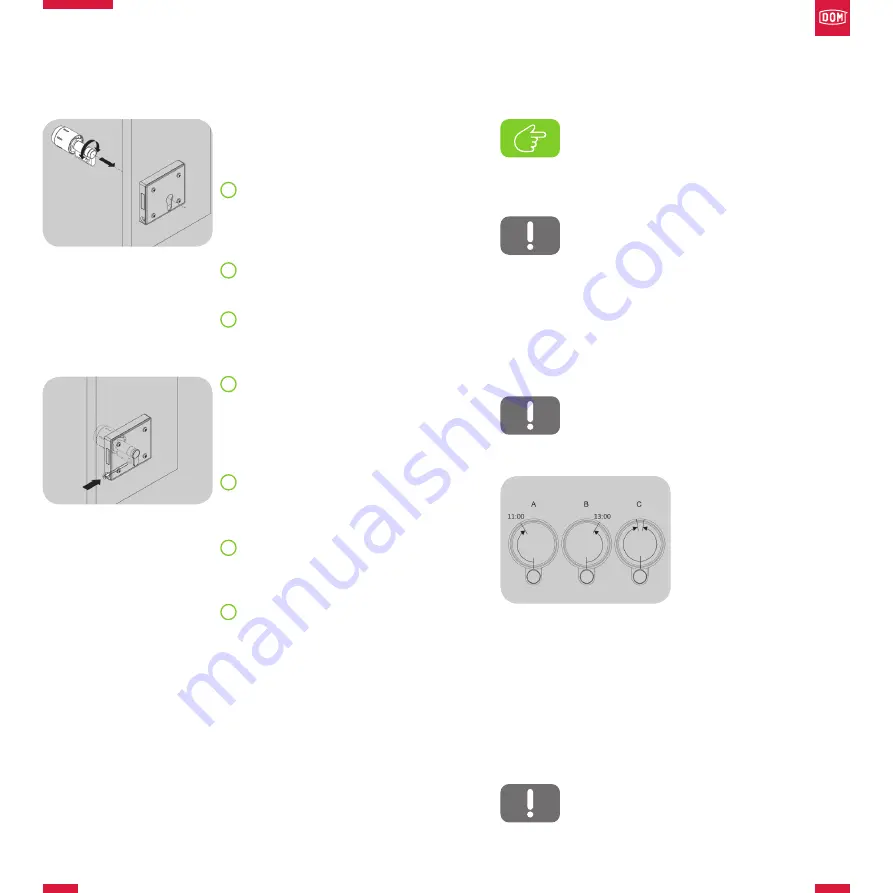

Fig. 32: Align cam

3

4

5

6

7

8

9

Fig. 33: Fix the Pro cylinder

Please note: The installation follows the same steps

as that of the Pro cylinder as described starting on

page 65. Observe the following information and fol-

low the installation description on page 65. Then

execute the functional test described here.

Caution: The figures starting on page 65 show the

installation situation with standard door handle.

When installing a

Pro cylinder EE

, the installation

sequence also applies for the installation situation

with panic bars according to DIN EN 1125 and and

handles or push pads according to DIN EN 179. The

order of installation remains the same and must be

adhered to under all circumstances. The informati-

on must always be observed. When in doubt, plea-

se contact the manufacturer.

Caution: After each installation, carry out a functio-

nal test. The knobs must return to their neutral po-

sition on their own after being rotated (cam flush).

A/B:

Turn the inside knob a

little more than a fourth of a

revolution in a clockwise or

counter-clockwise direction

(11 o‘clock or 1 o‘clock posi-

tion): The knob must return

to the neutral position on its

own in both cases (see Fig. C).

If the knob fails to turn back, realign the Pro cylinder

EE and check the lock for any defects.

C:

If you move the inside knob by approximately

one half-turn, the knob will remain in this position

for design reasons (dead centre area).

Caution: After installation, make sure the escape

door lock can be securely unlocked and opened ac-

cording to the specifications of the lock and fittings

manufacturers.

PRO CYLINDER EE

Fig. 34: Functional test