10

B. Turn Refrigerator On

This refrigerator is intended for con-

tinuous use. Do

NOT

allow it to run unattended

when there is a risk for loss of electricity or fuel.

Food spoilage could occur.

The lower and upper food compartments operate

independently. Each food compartment has a dedi-

cated set of controls.

Door

MUST

be open to access control panel.

See “A. Control Panel Buttons” on page

(7) for details on control settings and LED

indicators.

1.

UPPER FOOD COMPARTMENT

For an absorption system to function cor-

rectly, it

MUST

be level. See “E. Keep Re-

frigerator Level” on page (6).

For LP gas operation, manual gas valves

MUST

be open, and 12 Vdc power supply

(for controls)

MUST

be available.

a.

Press “ON/OFF” button (upper storage con-

trols) to turn power ON. See (FIG. 2).

b. Select mode of operation.

See “B. Modes Of Operation” on page

(9) for more details.

I. Auto mode - [default].

This mode is automatically selected when

power is turned ON.

II. LP gas (only) mode.

Press “Auto/Gas” button to select LP gas

mode.

If ignition cycle fails, see “A. Purge

LP Gas Lines” on page (10).

2.

LOWER FOOD COMPARTMENT

a.

Press “ON/OFF” button (lower storage con-

trols) to turn power ON. See (FIG. 3).

b. The mode of operation (ac/dc) is selected

automatically.

See “B. Modes Of Operation” on page

(9) for more details.

Failure to obey the following warnings could

result in death or serious injury:

●

FIRE OR EXPLOSION HAZARD.

BEFORE

refu-

eling or parking near a gasoline pump, make sure

ALL

LP gas appliances (vented to the outside of

RV) are shut

OFF

. Otherwise, fumes from gaso-

line pumps could come into contact with an LP

gas appliance burner flame and ignite.

●

FIRE HAZARD. Make sure there are

NO

obstruc-

tions (blockage) between burner jet and burner

tube

BEFORE

lighting LP gas burner.

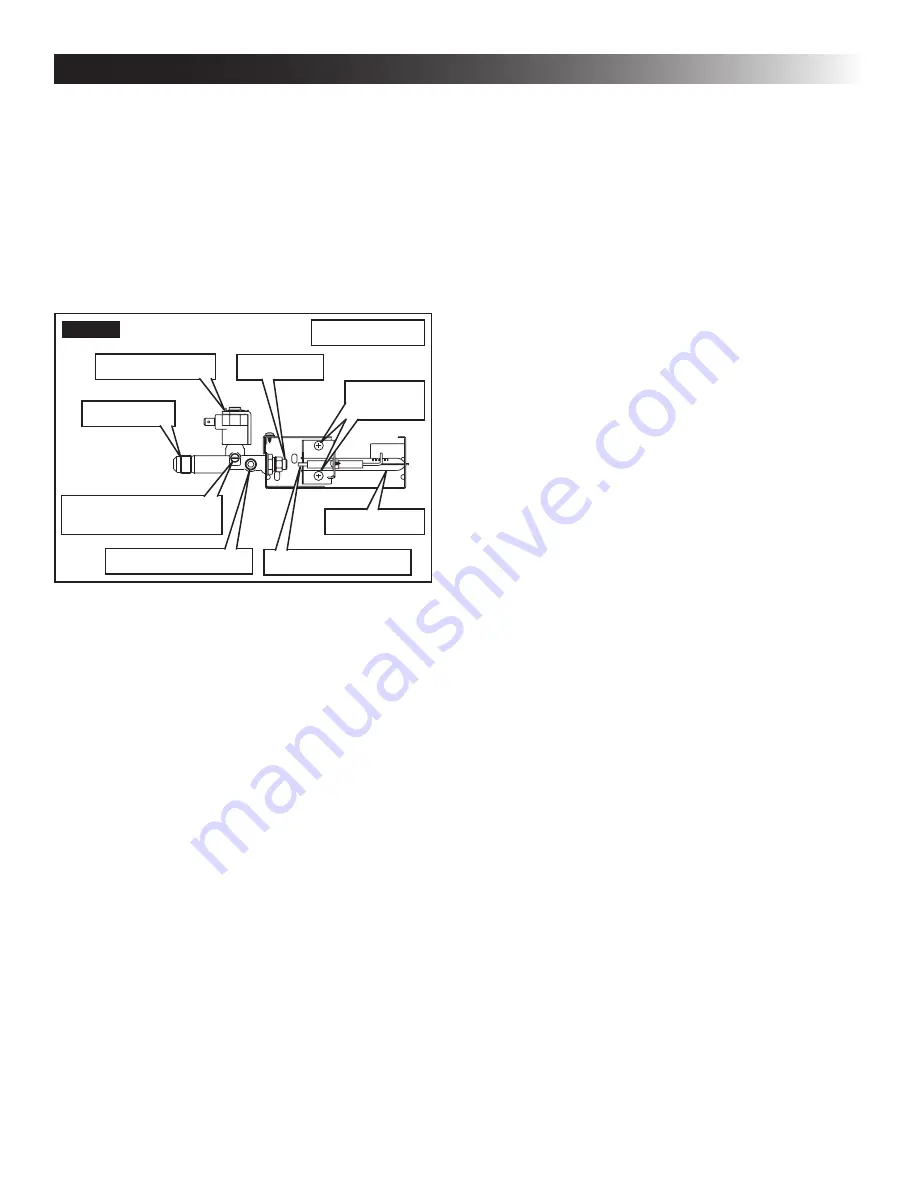

FIG. 4

Solenoid Valve

Mounting

Screws

Burner Jet

Manual Shutoff Valve

(In Open Position)

Burner Tube

Inlet Fitting

Lighter (Electrode)

Pressure Test Port

LP Gas Burner

A. Purge LP Gas Lines

If air is trapped in LP gas (supply) lines, the refrig-

erator will not operate in LP gas mode.

Common causes for air in LP gas lines:

●

Refrigerator has not operated in LP gas mode

for a long time.

● LP gas tanks have been replaced or refilled.

To purge trapped air from LP gas lines, perform the

following procedure:

1.

Press “ON/OFF” button twice (upper storage

controls) to cycle power OFF and ON. See

(FIG. 2).

Door

MUST

be open to access control

panel.

2. Press “Auto/Gas” button to select LP gas mode,

and start ignition cycle. See (FIG. 2).

a. The lighter sparks for approximately 45 sec-

onds. See (FIG. 4).

b.

If first attempt fails, the lighter repeats up to

3 times.

There is a 2 minute rest period be-

tween each attempt.

3. Repeat steps (1) through (2) if ignition cycle fails.

If ignition cycle fails after 4 attempts,

see “Appendix A: Troubleshooting” on

page (18).

START / STOP REFRIGERATOR