9

There is a 2 minute rest period be-

tween each attempt.

III. If ignition cycle fails, upper compartment

remains OFF, and will not cool.

To attempt a new ignition cycle for

LP gas operation, see “A. Purge LP

Gas Lines” on page (10).

3.

LOWER FOOD COMPARTMENT

The lower food compartment (drawer) operates

on electric power only. The power source is au-

tomatically selected in the following order:

a. 120 Vac - [default].

The lower compartment attempts to operate

on 120 Vac power first.

120 Vac is

ALWAYS

the primary

source of power. The lower compart-

ment reverts back to 120 Vac (from 12

Vdc) whenever it becomes available.

b. 12 Vdc - [secondary].

The lower compartment automatically

switches to 12 Vdc power if 120 Vac is un-

available.

If 120 Vac becomes available during

12 Vdc operation, the lower compart-

ment automatically switches back to

120 Vac power.

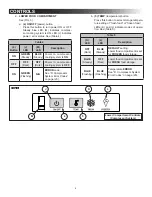

C. Temperature (Thermostat) Control

See “A. Control Panel Buttons” on page

(7) for details on control settings and LED

indicators.

1.

UPPER FOOD COMPARTMENT

The upper food compartment has (3) tempera-

ture modes (settings):

a. Cold (minimum cooling level).

b. Colder (intermediate cooling level).

c. Coldest (maximum cooling level).

2.

LOWER FOOD COMPARTMENT

The lower food compartment has (2) tempera-

ture modes (settings):

a. Frozen food (freezer) mode - [default].

b. Fresh food (refrigerator) mode.

Before changing temperature

setting from fresh food to freezer, make sure

interior surfaces are completely dry. Other-

wise, drawer slides may freeze up, making

drawer operation difficult.

B. Modes Of Operation

See “A. Control Panel Buttons” on page

(7) for details on control settings and LED

indicators.

1.

STANDBY MODE

If refrigerator controls cannot read food com-

partment temperature, or if temperature is out-

side normal operating range, the affected sys-

tem switches to standby mode. The refrigerator

continues to operate using any available energy

source.

Standby mode for upper food compartment runs

the absorption system continuously. This could

cause fresh food items to freeze.

Standby mode for lower food compartment runs

the compressor system on an intermittent cycle.

This could cause frozen food items to thaw, or

fresh food items to freeze.

For either incident, the affected cooling system

remains in standby mode until sensor failure is

repaired and system is reset.

2.

UPPER FOOD COMPARTMENT

The upper food compartment operates on (2)

power modes:

a. Auto mode - [default].

In this mode, the power source is automati-

cally selected in the following order:

I. 120 Vac - [default].

Electric power takes priority in this mode.

The upper compartment attempts to op-

erate on electric power first.

Electric power is

ALWAYS

the pri-

mary source of power. The upper

compartment reverts back to elec-

tric power (from other power sourc-

es) whenever it becomes available.

II. LP Gas - [secondary].

The upper compartment automatically

switches to LP gas if electric power is un-

available.

If electric power becomes available

during LP gas operation, the upper

compartment automatically switch-

es back to electric power.

b. LP gas mode.

In this mode, the upper compartment only

operates on LP gas. The ignition cycle pro-

ceeds to light the LP gas burner in the fol-

lowing order:

I. The lighter sparks for approximately 45

seconds.

II.

If first attempt fails, the lighter repeats up

to 3 times.

CONTROLS