15

- Insert locking-panel, secure with screws.

- Reinstall

lock

(see 2.2.4)

- Reinstall

door

(see 2.2.1)

2.3. Electrical

component

(Fuzzy logic solution)

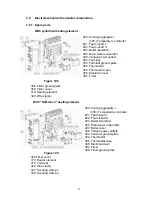

2.3.1. Replacing lighting device and bulb

- Remove screws securing lighting device.

(Figure 46)

- Detach blocking tab on reflector from the lighting device by pressing the

reflector plate. At the same time, push the light shield off of the casing.

(Figure 47,48)

- Unscrew

bulb.

(Figure 49)

- Snap the lighting device open by detaching the tab behind the threaded

part of the casing with a screwdriver.

(Figure 50)

- Disconnecting electrical wires, removing defective lighting device.

- Reconnecting electrical wires in new casing. Prior to wiring, wires must be

threaded in the appropriate bore of the reflector holder.

(Figure 51)

- Placement of the socket in the casing so that its securing rib fits in the

groove of casing. Screws securing the wires must stand outwards from

lighting device.

(Figure 52)

Figure 46

Figure 47

Figure 48

Figure 49

Figure 50