(22)

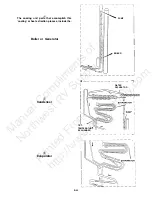

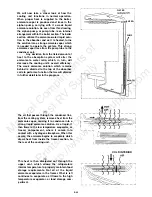

The coach vent system must be able to provide

a way to direct the hot air, produced by the

action of the cooling unit, out away from the

installation of the refrigerator.

(23)

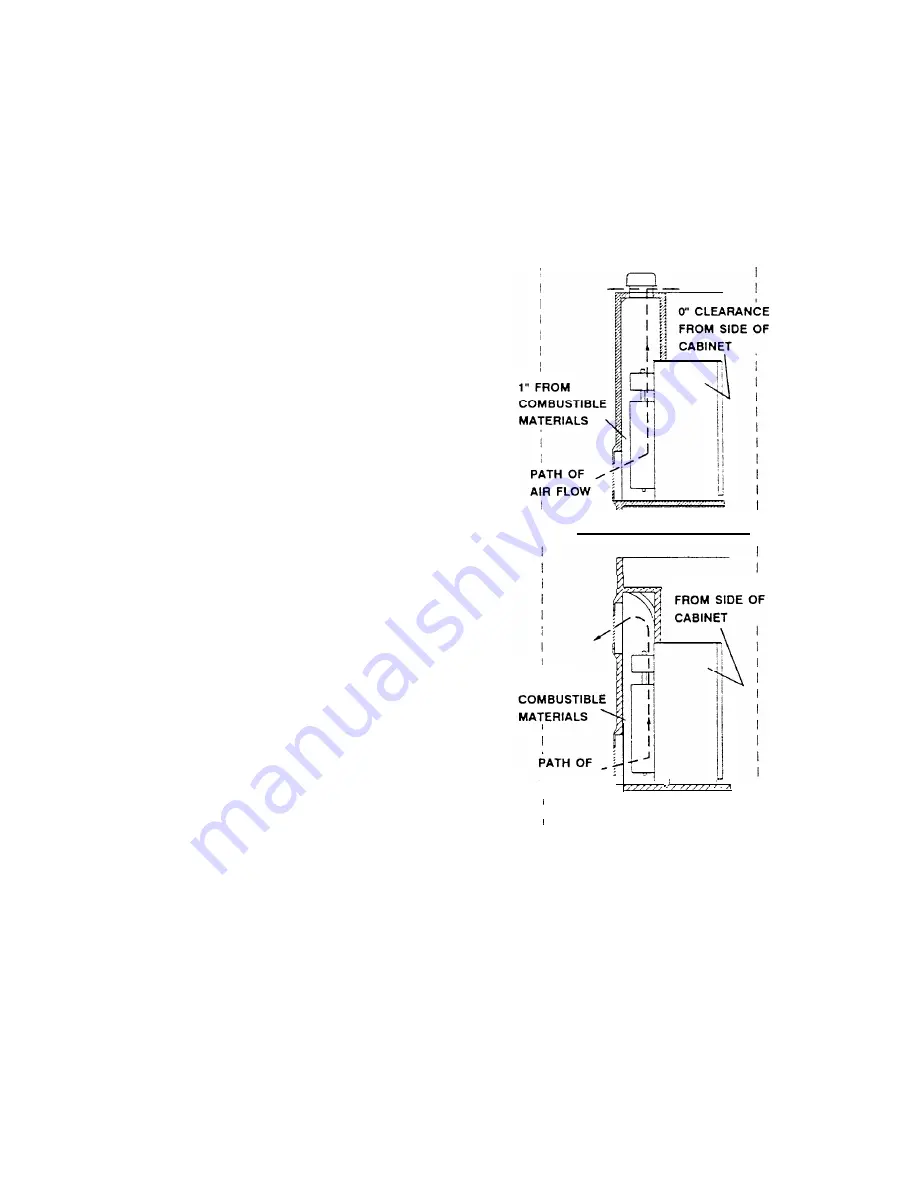

In a good installation there should be as little

open space as possible surrounding the sides

and top of the refrigerator to achieve proper air

flow. All potential dead air pockets should be

blocked or baffled to insure that heat from the

cooling unit won’t be trapped in these spaces

and reduce efficiency. In addition, the cooling

unit should be at least one inch from the

nearest surface made of combustible materials.

Please follow the installation manual for proper

dimensions and clearances.

RVIA requires that the refrigerator be

installed in such a manner as to provide

complete separation of the combustion system

and the interior atmosphere of the recreational

vehicle. This regulation requires all seams and

joints in the enclosure be sealed. The under-

counter installation is different. The addition of

a metal chute the width of the enclosure, that

extends from the upper side vent, will help

eliminate the possibility of dead air pockets. It

helps direct the hot air out the exhaust vent.

The best method for venting the absorption

refrigerator is with a lower side vent and a roof

vent. Using proper Dometic vents will give you

sufficient intake and exhaust areas for ventila-

tion

(24)

Heat application to the boiler section of the

cooling unit must be within the designed BTU’s.

Never oversize the heating element on AC or

DC power source. Always use the proper size

orifice for gas modes. As explained earlier, any

deviation will cause a potential cooling unit

failure.

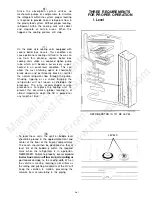

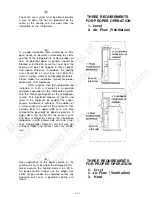

THREE REQUIREMENTS

FOR PROPER OPERATION

1. Level

2. Air Flow (Ventilation)

-------- ----- 1

I I

0" CLEARANCE

1"

FROM

AIR FLOW

I

I

I I

- - - - - - - - - - - -

J

THREE REQUIREMENTS

FOR PROPER OPERATION

1. Level

2. Air

Flow (Ventilation)

3. Heat

D-6-9

Manual

Compliments

of

Northwest

RV

Supply

Printed

From

http://www.nwrvsupply.com