6

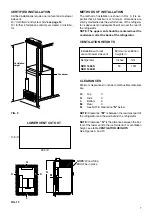

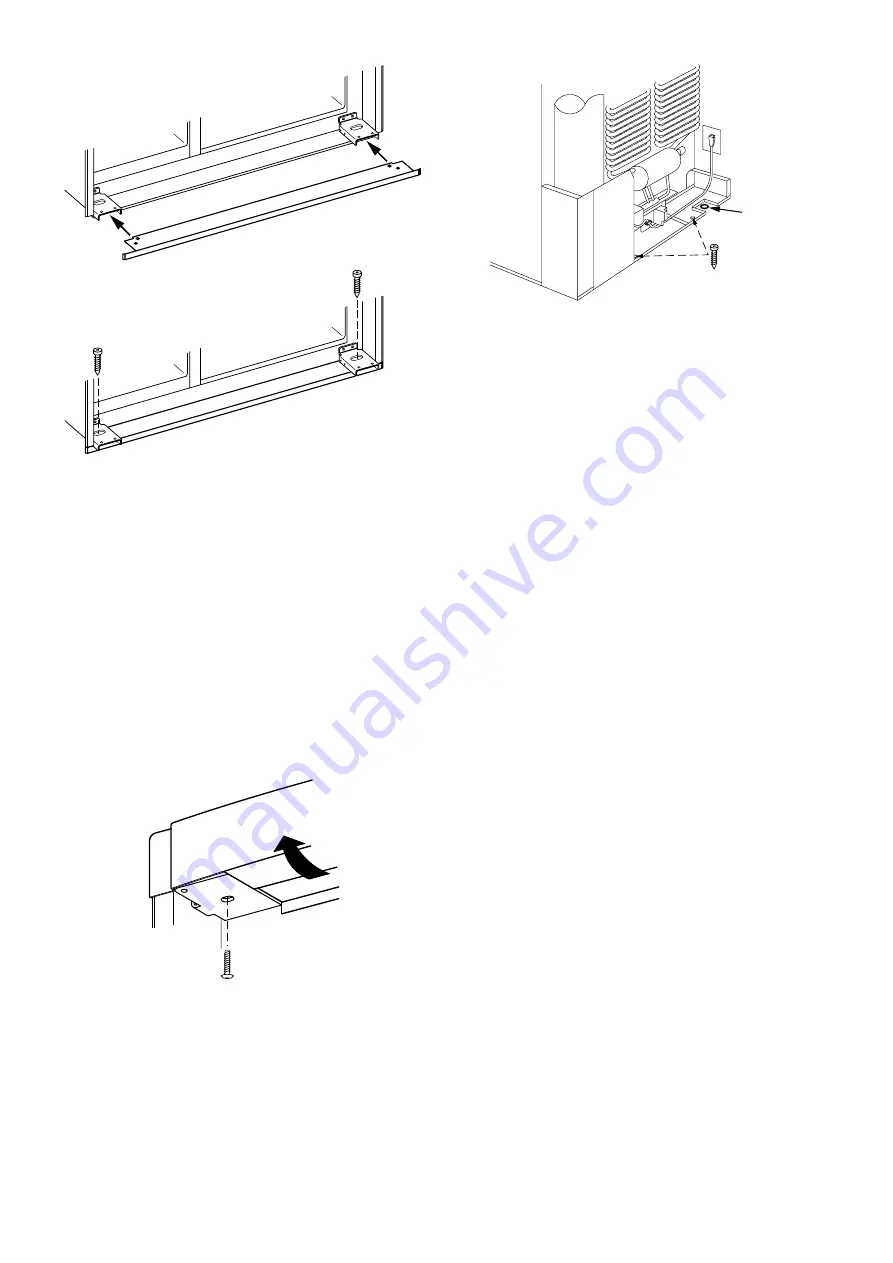

2. Secure the refrigerator and the lower front strip with

two screws: One screw through each hinge. See

FIG 6.

Step 2: Two screws installed in the top frame.

The top decoration panel must be removed from the re-

frigerator before the screws can be installed.

Open the doors and remove the four screws that secure

the top decoration panel to the top frame. Two screws

are accessible from underneath see FIG. 7, the second

two screws that secure the decoration panel to the front

frame are located on each side of the lock retainer.

Carefully tilt the top decoration panel and lift up to re-

move from top frame. Be careful not to damage the cir-

cuit board and wires.

Any space between the counter, storage area or ceiling

and top of the refrigerator greater den 1-1/2 inches should

be blocked. The heat produced at the rear of the refrig-

erator will become trapped in this space, making the top

of the refrigerator hot and reduce the efficiency of the

refrigerator.

Drain water hose

A hole must be drilled through flooring see FIG. 8.

The hole must be drilled in the cut out opening of the

base plate at the rear of the refrigerator. The installer

MUST make sure that the hose does not kink when run

through the floor. Seal around the hose that goes through

the drilled hole. If a longer hose than supplied is required

to get the water to drain outside of the vehicle, the in-

staller will have to supply the extra length of hose.

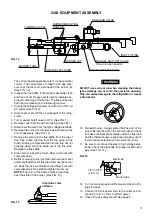

TESTING LP GAS SAFETY

SHUTOFF

The gas safety shutoff must be tested after the re-

frigerator is connected to LP gas supply.

To test the gas safety shutoff, proceed as follows:

1. Start the refrigerator according to the instructions,

and switch to GAS mode. (See start up instruc-

tions).

2. Check that the gas flame is lit and the GAS mode

indicator lamp (C) is on.

3. Close the manual gas shutoff valve at the back of

the refrigerator. (See FIG. 1).

4. Wait for one minute. The CHECK indicator lamp

(D) should be on and the GAS mode indicator lamp

(C) should be off.

5. Remove protection cover (see FIG. 1) and open

the manual gas shutoff valve. Do not change any

button positions on the control panel. Apply a

noncorrosive commercial bubble solution to the

burner jet orifice.

6. No bubbles should appear at the opening of the

burner jet orifice. The presence of bubbles indi-

cates a defective gas safety shutoff, and service is

required.

7. If no bubbles were present at the burner jet orifice,

it should be rinsed with fresh water. Be careful not

to damage the burner jet orifice. Replace cover and

press the main power ON/OFF button (1) OFF and

back ON. Normal operation of the burner should

return. Allow the burner to operate for a minimum

of five minutes.

Install the two screws in the top frame, the holes are

accessible from underneath.

Seal the opening for the screws with aluminum tape.

Replace the top decoration panel with its four screws.

Be careful not to pinch the wires behind the panel.

STEP 3: Two screws installed in the rear base.

See FIG. 8.

Failure to follow the sequence in securing refrigerator in

enclosure can cause leakage between the frame and

cabinet.

FIG. 7

Hole for drain

water hose

FIG. 8

FIG. 5

FIG. 6

Summary of Contents for NDR1492-B

Page 2: ......

Page 16: ...16 MO FO 0222...