17

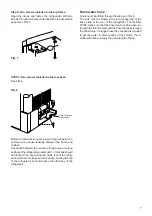

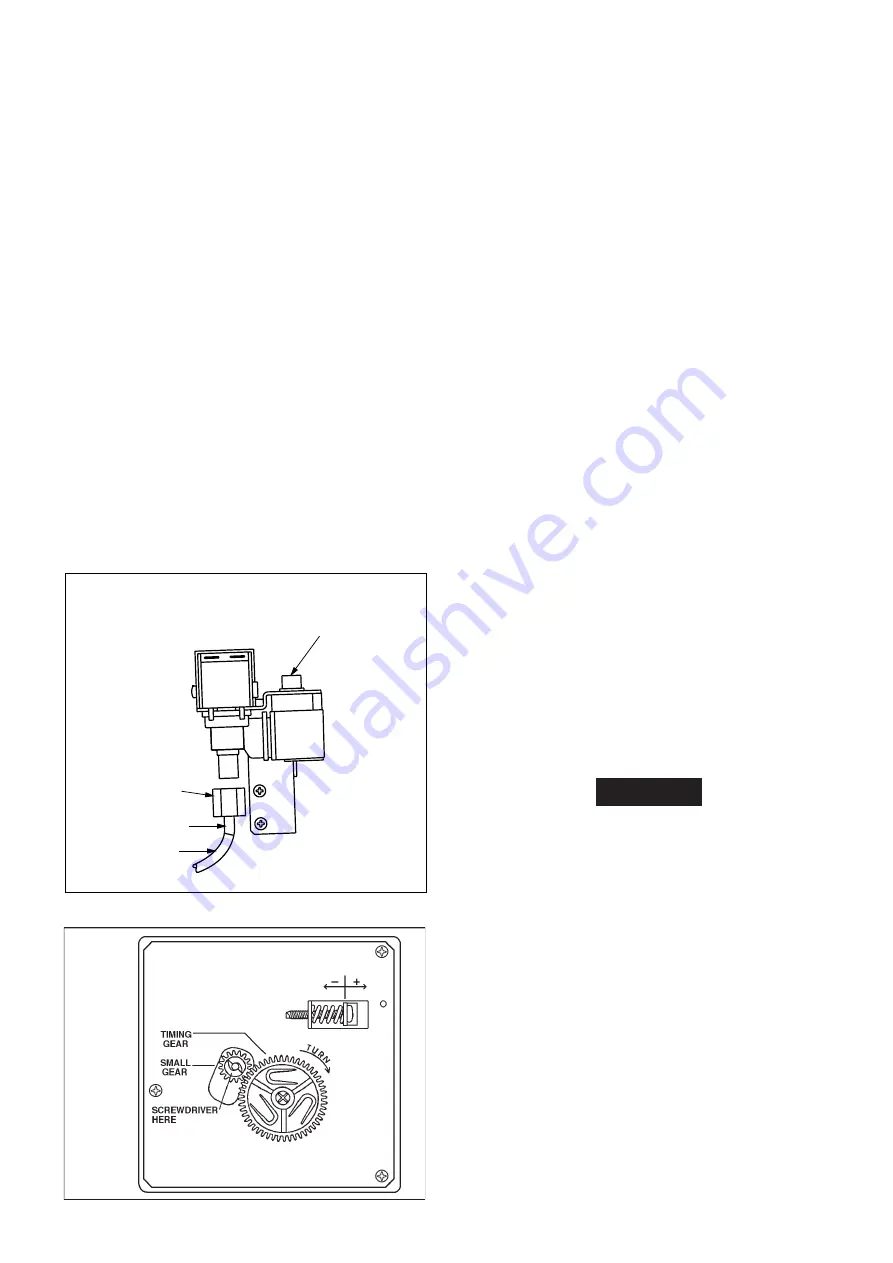

6. Connect compressed air onto the inlet fitting of the

water solenoid valve. See FIG. 14. Apply AC power

to the solenoid valve by forcing the ice maker mold

assembly through several harvest cycles. Remove

the plastic cover from the mold assembly. The bail

arm must be in the down (“ON”) position. Start the

harvest cycle with a flat blade screw driver inserted

into the center of the small gear. Turn the gear

counterclockwise, when the hold switch closes, the

mold assembly will continue to operate through the

harvest cycle. See FIG. 15. During the water fill

sequence of the harvest cycle the compressed air

will blow out the water trapped in the solenoid

valve. Repeat the harvest cycle operation several

times.

Note: Up to 20 PSIG air pressure can be used to clear

the solenoid valve. Damage to solenoid can occur if AC

power is applied for more than 20 seconds.

7. Make sure that the metal tube is in the plastic water

line to the ice maker. Reconnect and tighten lines

on water solenoid valve. Leave the water supply

turned off until temperatures are above 0°F/-18°C.

See figure 14.

8. Dry out ice maker mold assembly with a soft cloth.

Place bail arm in the “UP/OFF” position.

FIG. 15

MAINTENANCE & SERVICE

The user should be aware of service that must be

done on a regular schedule to keep the refrigerator

operating properly. The service should only be per-

formed by a qualified technician who is familiar with

refrigerators.

1. REFRIGERATOR REMOVAL

Before working on the refrigerator, make sure the AC

voltage and DC voltage leads are disconnected.

Loosen the screws anchoring the refrigerator to the

enclosure and slide the refrigerator out of the com-

partment.

When replacing the refrigerator make sure that the

sealing strips are properly positioned.

Replacement is the reverse of removal.

Refer to section INSTALLATION, page 5 to 9.

2. PERIODIC MAINTENANCE

To keep your Dometic refrigerator operating efficiently

and safely, periodic inspection and cleaning of sev-

eral components once or twice a year is recom-

mended.

A. It is important to keep the area at the back of the

refrigerator clean. Check the lower vent, upper vent

and area between these openings for any obstruc-

tions such as bird/insect nests, spider webs, etc.

Clean the coils on the back of the refrigerator. Use

a soft bristled brush to dust off the coils. The entire

cooling unit at the back must be kept clear from all

kinds of object that obstruct the air flow.

It is important to keep the refrigerator area free from

combustible material, gasoline and other flammable

vapors or liquids.

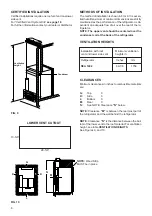

3. REPLACING A HALOGEN LAMP

FIG. 14

Inlet fitting for

water supply line

Plastic nut

Metal tube

1/4” Water line

to ice maker

Water solenoid valve

! CAUTION

Turn off the refrigerator before replacing the lamp.

Wear gloves as protection against hot lamp, broken

glass and as protection of the new lamp.

Refrigerator

The lamp is located at the top of the refrigerator com-

partment.

To replace the lamp proceed as follows:

•

unhook the tab on the lamp cover by pressing in

with the thumb on the side of the lamp cover.

•

remove the lamp cover.

•

with gloves, pull out the lamp from the socket and

replace it with a new 12V, 10-watt (maximum)

halogen lamp base G4.

•

replace the lamp cover by placing the two tabs into

the corresponding slots of the lamp house and

press the tab into place.