SPECIAL HINTS

Note. Do not install the appliance directly on carpeting.

Carpeting must be protected by a metal or wood panel

beneath the appliance which extends at least full width and

depth of the appliance.

The refrigerator must be installed in a substantial

enclosure and must be level. A spirit level is supplied

with each refrigerator and by placing it in the freezer com-

partment one can level the refrigerator both ways front to

back and side to side. When installing the refrigerator in

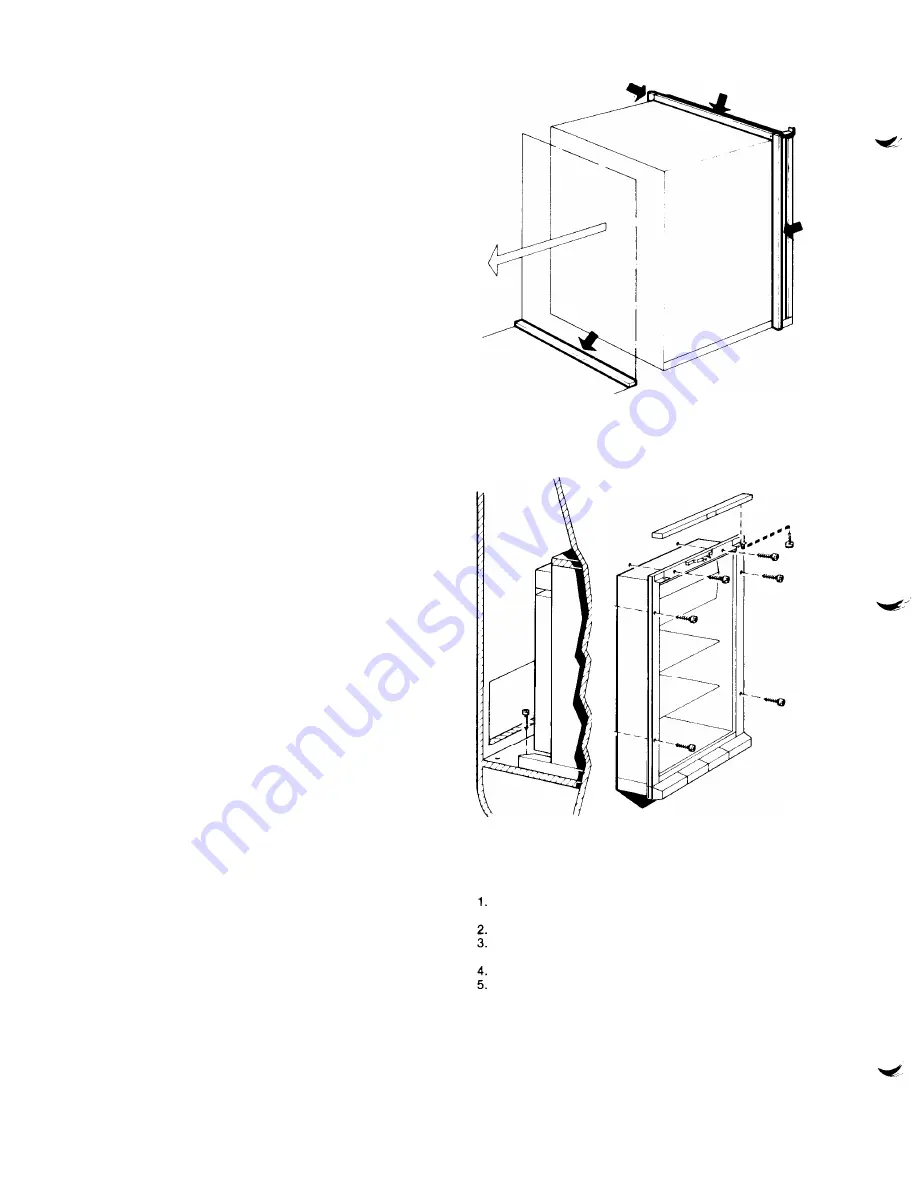

the enclosure care should be taken to ensure a complete

sealing between the front frame of the refrigerator and

the top, sides and bottom of the enclosure. For this

purpose a length of sealing strip is applied to rear sur-

faces of the front frame. A sealing strip should also be

applied to the foremost floor of the enclosure as shown

in fig 8. The sealing strip should provide a complete isola-

tion of the appliance combustion system from the vehicle

interior.

Be careful not to damage the sealing strip applied to the floor of

the enclosure when the refrigerator is put in place.

In the front frame and in the base at the rear of the refrigerator

there are holes for screws for fixing the refrigerator in the enclo-

sure. See fig. 9.

Any space between counter or storage area and the top of the

refrigerator greater than 1 1/2" should be blocked. The heat pro-

duced at the rear of the refrigerator will otherwise become trap-

ped in this space making the top of the refrigerator hot and

reducing the efficiency of the refrigerator.

TO REMOVE AND REPAIR

THE REFRIGERATOR

Before working on the refrigerator, make sure that 120 V A.C.

and optional 12 V DC. Leads are disconnected. Close the gas

valve. Unscrew the hexagon nut (#11 Fig. 2) and move the

Valve on the gas line out of the bracket. Check that the valve

slips out of the clip connection with the switch shaft.

Loosen the screws fixing the refrigerator to the enclosure and

remove the refrigerator.

When replacing the refrigerator make sure that the sealing strips

are properly positioned. After reassembly the gas connection

should be checked for leaks.

TEST OF THE GAS SAFETY SHUTOFF

The gas safety shutoff device must be tested after the refrigera-

tor is placed in operation.

Refrigerator wlth piezo ignitor. (Figure 1)

1.

2.

3.

4.

5.

6.

Start the refrigerato;according to the instruction

for gas operation with piezo igniter.

Check that the gas flame is lit. This can be observ-

ed through the reflector (E).

Close the gas valve by turning the knob (A) back to

position “OFF”.

Wait 1 minute.

Remove cover plate, see (46) in fig 1. Open the gas

valve by turning the knob (A) to position “GAS”

without pushing the button (C) and (D). Test that no

gas comes through the jet, (item 38.) Use soap

water solution. Be careful not to damage the jet.

After test, rinse the jet with water. Once more be

careful no to damage the jet. Assemble the cover

plate. Start the refrigerator by following the instruc-

tion for gas operation with piezo igniter. Normal

gas operation should now return. Operate for at

least 5 minutes.

Fig.8

Fig.9

Refrigerator with automatic reigniter. (Fig 2 & 3)

6.

Start the refrigerator according to the instruction

for gas operation with automatic reigniter.

Check that the gas flame is lit. The lamp (E) is out.

Close the gas valve by turning the knob (A) back to

position “OFF”.

Wait 1 minute, disconnect 12 V D.C.

Remove cover plate, see (46) fig. 2 for RM2500 and

(55) fig. 3 for RM2600/2800. Open the gas valve by

turning knob (A) to position “GAS” without pushing

the button (C). The igniter will not spark. Test that

no gas comes through the jet, (item 38). Use soapy

water. Be careful not to damage the jet.

After the test rinse the jet with water. Once more

be careful not to damage the jet. Assemble the

cover plate. Connect the 12 V D.C. again. Start the

refrigerator by following the instruction for gas

operation with automatic reigniter. Normal gas

operation should now return. Operate for at least 5

minutes.

Summary of Contents for RM2300

Page 11: ......