7

Check that the gas supplied to the refrigerator is at

the correct pressure.

CAUTION

CONNECTIONS

LP gas connection

The gas installation and servicing must be carried out by an

authorised person and conform to all relevant local authori-

ties.

The refrigerator is

not

designed for operation on town gas or

natural gas but for operation on LP gas, the pressure of which

must be 2,72 kPa for Propane. Check that this is stated on

the data plate. The gas supply system must incorporate an

approved gas pressure regulator to maintain a supply pressure

of 2,7 kPa.

Hook up to the gas supply line is accomplished at the manual

gas valve, which is furnished with a ISO 7/1 -Rp 1/8 internal

pipe thread connection. All completed connections should be

checked for leaks with soapy water.

The gas supply system must incorporate an approved gas

pressure regulator to maintain a supply pressure of 2,72 kPa .

When testing the gas supply system at test pressures in excess

of 1/2 psi, the refrigerator and its individual shutoff valve

must be disconnected from the gas supply piping system.

When testing the gas supply system at pressures less than or

equal to 1/2 psi, the appliance must be isolated from the gas

supply piping system by closing its individual manual shutoff

valve.

If detailed instructions on the installation and connection to

the gas supply are required, contact your dealer or distributor.

Testing LP gas safety shut off

The gas safety shut off must be tested after the refrigerator is

connected to the LP gas supply.

To test the gas safety shutoff, proceed as follows:

Start the refrigerator and check that the gas flame

is lit. This can be observed on the flame indicator

E

. The red indicator is in the green field (ON).

Close the gas valve by turning knob

A

back to

“OFF” position.

Wait for one minute.

Remove protection cover.

Open the gas valve by turning knob

A

to position

“GAS” without pressing buttons

C

and

D

.

Apply a non-corrosive commercial bubble solution

to the burner jet. Be careful not to damage the

burner jet.

1.

2.

3.

4.

5.

6.

INSTALLATION INSTRUCTIONS

No bubbles should appear at the opening of the

burner jet. The presence of bubbles indicates a de-

fective gas safety shutoff, and service is required.

If no bubbles were present at the burner jet, the gas

safety valve is working properly.

Rinse jet thoroughly with fresh water before pro-

ceeding. Be careful not to damage the burner jet.

Replace the protection cover and turn the main

switch OFF and back ON.

Normal operation of the burner should return.

Allow the burner to operate for a minimum of 5

minutes.

Electrical connection

230-240 v AC connection

The electrical installation must be carried out in a proper and

durable manner, taking into account all relevant regulations

and codes of practice.

Check that the voltage stated on the data plate is the same as

the main voltage in use (230-240 V). Electrical leads must be

routed and secured so that they cannot come into contact with

hot or sharp parts of the refrigerator.

For mains voltage operation, it is important that the cir

-

cuit to and in the caravan is effectively earthed

.

The refrigerator is equipped with a three-prong (grounding)

plug for your protection against shock hazards and should

be plugged directly into a properly grounded threeprong

receptacle.

Note!

Do not cut or remove the grounding prong

from this plug.

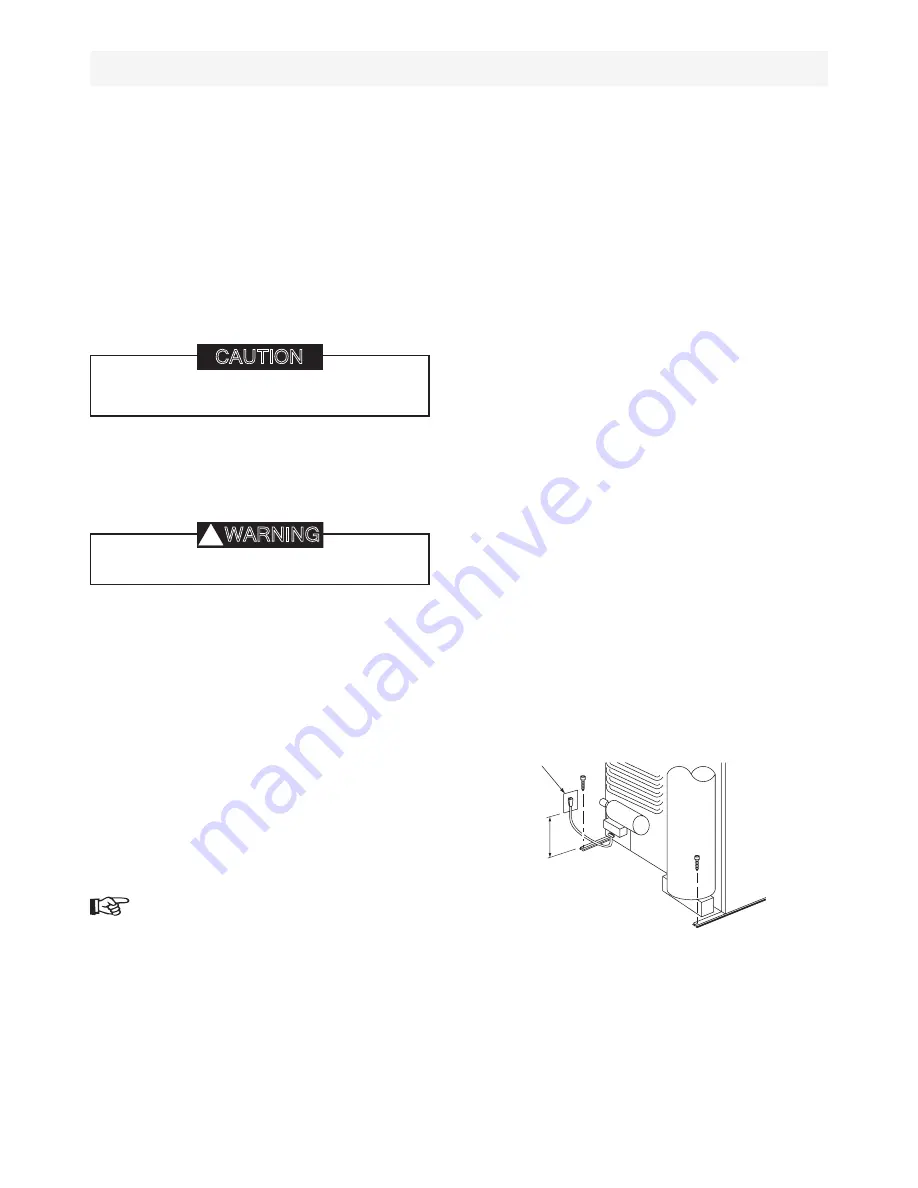

The free length of the cord is 6 ft. (1,8 m). It is recommended

the receptacle placed on the left side of the refrigerator

(viewed from the rear) and approximately 150 mm from the

floor. This will allow easy accessibility through the vent door.

Exchange of supply cord

The cord should be routed to avoid direct contact with the

burner cover, flue cover or any other components that could

damage the cord insulation. If the supply cord is damaged,

it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard.

7.

8.

9.

10.

230-240 VAC

receptacle

150 mm

Do not use an open flame to check for gas leaks.

WARNING

!

Summary of Contents for RM2453 and

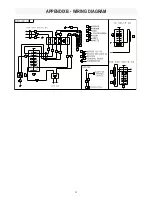

Page 15: ...15 Appendix B wiring diagram...

Page 16: ......