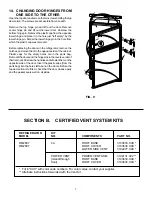

10

3-WAY MODEL

A. A 12 volt DC supply must be available for the electronic

control to function.

B. Press the main power ON/OFF button (1) to the DOWN

position.

C. Press the TEMPERATURE SELECTOR BUTTON (4) 3-

WAY Model until the lamp at the desired setting is

illuminated.

D. AUTO MODE

1. Press the DC mode selector button (2) to the UP (OFF)

position.

2. Move the AUTO/GAS mode selector button (3) to the

DOWN position. (If 120 volts AC is available, the AC

mode indicator lamp (B) will illuminate indicating AC

operation. If 120 volts AC is not available, the GAS mode

indicator lamp (C) will illuminate and the control system

will automatically switch to GAS operation.

3. If the CHECK indicator lamp (E) illuminates and the GAS

mode indicator lamp (C) is off, the controls have failed to

ignite the burner in the GAS mode. GAS operation may

be reset by pressing the main power ON/OFF button (1)

to the OFF then ON position. (See Step 3, under GAS

MODE).

4. Press the TEMPERATURE SELECTOR button (4) until

the lamp at the desired position is illuminated.

5. When operating in the AUTO mode, the AUTO modes

indicator lamp (D) will illuminate. The control system will

automatically select between AC and GAS operation

with AC having priority over GAS. Either the AC indicator

lamp (B) or the GAS indicator lamp (C) will illuminate

depending on the energy source selected by the control

system. If the control system is operating with AC energy

and it then becomes available, the system will automati-

cally switch to GAS. As soon as AC becomes available

again the control will switch back to AC regardless of the

GAS operation.

E. GAS MODE

1. Press the DC mode button (2) to the UP (OFF) position.

2. Move the AUTO/GAS mode selector button (3) to the UP

position. The GAS mode indicator lamp (C) will illumi-

nate. After 45 seconds the burner should be ignited and

operating normally.

3. On the initial refrigerator start-up, it may take longer than

45 seconds to allow air to be purged from the gas line. If

the gas does not ignite within 45 seconds, the CHECK

indicator lamp (E) will illuminate and the GAS mode

indicator lamp (C) will go off. To reset when the CHECK

indicator lamp (E) is illuminated, press the main power

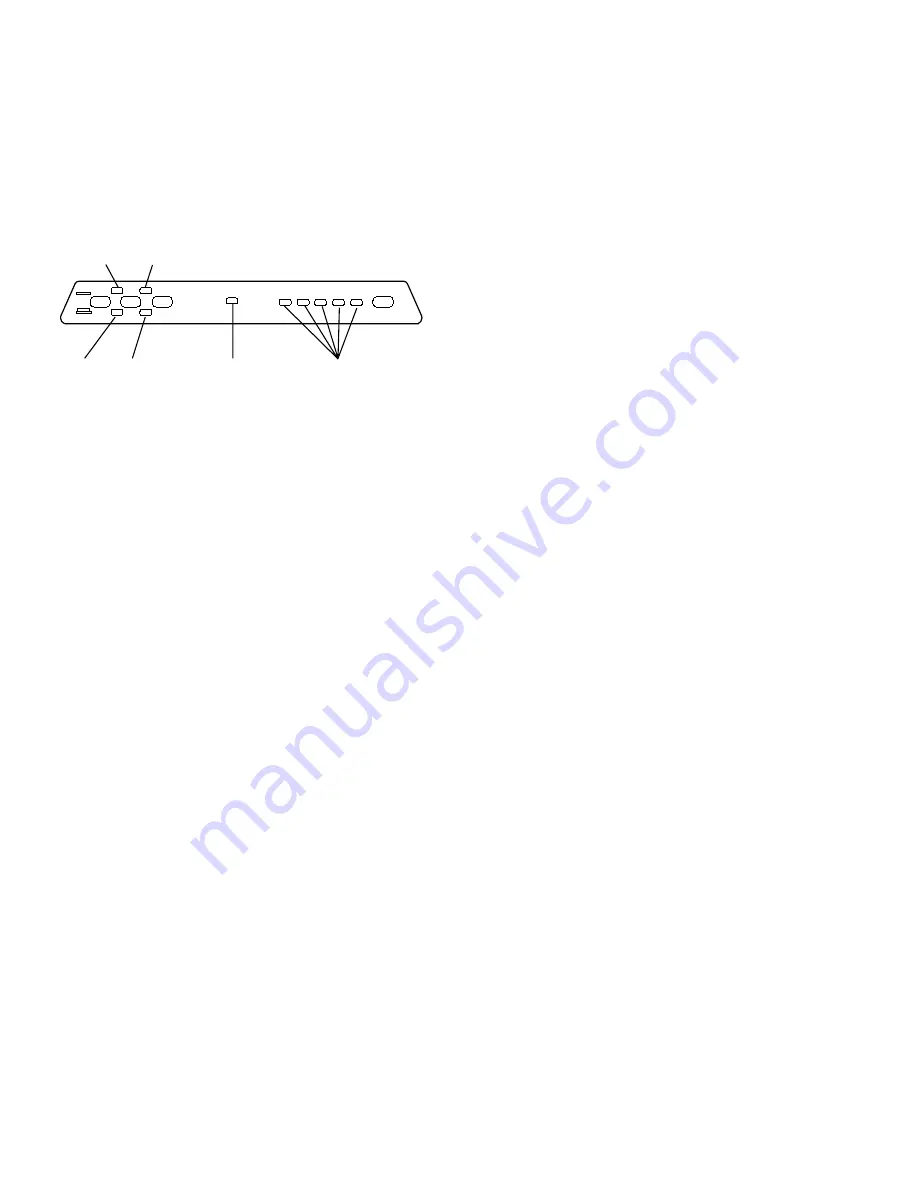

ON

OFF

AUTO

AC

GAS

1

CHECK COLD 1 2 3 4 5 COLDEST

4

2

3

F

E

C

B

D

A

ON/OFF button (1) to the OFF and then ON position.

If the control is switched to AC or DC operation while the

CHECK indicator lamp is on, it will function properly but

the CHECK indicator lamp will not go off until the main

power ON/OFF button is pressed to the OFF then ON

position.

NOTE:

Do not continue to reset GAS operation if the

CHECK indicator lamp continues to be illuminated after

several tries. If repeated attempts fail to start the LP gas

operation, check to make sure that the LP gas supply

tanks are not empty and all manual shutoff valves in the

lines are open. If the problem is still not corrected,

contact a service center for assistance.

4. Press the TEMPERATURE SELECTOR button (4) until

the lamp at the desired position is illuminated.

When operating in the DC mode, the DC mode indicator lamp

(A) will be illuminated. All other mode lamps will be off. The

DC mode overrides all other operating modes. If one of the

other operating modes is desired, the DC selector button (2)

must be in the UP (OFF) position.

G. BATTERY PROTECTION SYSTEM

The control system is equipped with a battery protection

system. A steady illuminated DC mode lamp (A) indicates

that sufficient voltage is present at the terminal block

connections to operate the refrigerator normally. If the input

voltage is below approximately 12.8 volts DC or should it

drop below 12.8 volts DC during operation, the DC mode

lamp (A) will flash ON and OFF to signal a low battery

condition. In this condition the control will continue to operate

in DC mode for a maximum of 10 minutes.

H. THERMOSTAT

The thermostat on the refrigerator controls both the gas and

electric operation, thereby eliminating the necessity of

resetting each time a different energy source is employed.

After initial start-up, the thermostat should be moved from

"COLDEST" to the desired temperature setting, usually

about mid-setting.

I. STANDBY MODE OF OPERATION

This control system contains a feature where it will continue

to operate the cooling system in the event of a failure of a

major operating component. Two different modes of opera-

tion can occur in this category.

If for some reason the display module becomes nonfunc-

tional, the control system will revert to fully automatic

operation - selecting the best energy source available with

AC and GAS priority. The temperature of the refrigerator will

be maintained at the MID position within normal temperature

tolerances. The power module will continually attempt to

reestablish operation of the display module.