4

7.

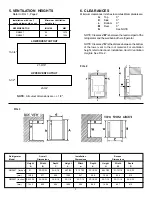

INSTALLING REFRIGERATOR IN

ENCLOSURE

NOTE: DO NOT install the appliance directly on carpeting.

Carpeting must be removed or protected by a metal or wood

panel beneath the appliance, which extends at least the full

width and depth of the appliance.

INSTALLATION: The refrigerator must be installed in a

substantial enclosure and must be level. When installing the

refrigerator in the enclosure, be certain there is a complete

seal between the front frame of the refrigerator and the top,

sides and bottom of enclosure. A length of sealing strip is

applied to the rear surface of the front frame for this purpose.

Also apply a sealing strip to the foremost floor of the

enclosure and apply a second sealing strip to the bottom of

the trim strip on the front base as shown in FIG. 4. The

sealing should provide complete isolation of the appliance's

combustion system from the vehicle interior.

The dimensions shown in FIG. 3 will give you adequate

space for service and proper installation.

NOTE: Be careful not to damage the sealing strip applied to

the floor of the enclosure when the refrigerator is put in place.

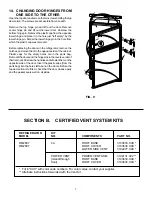

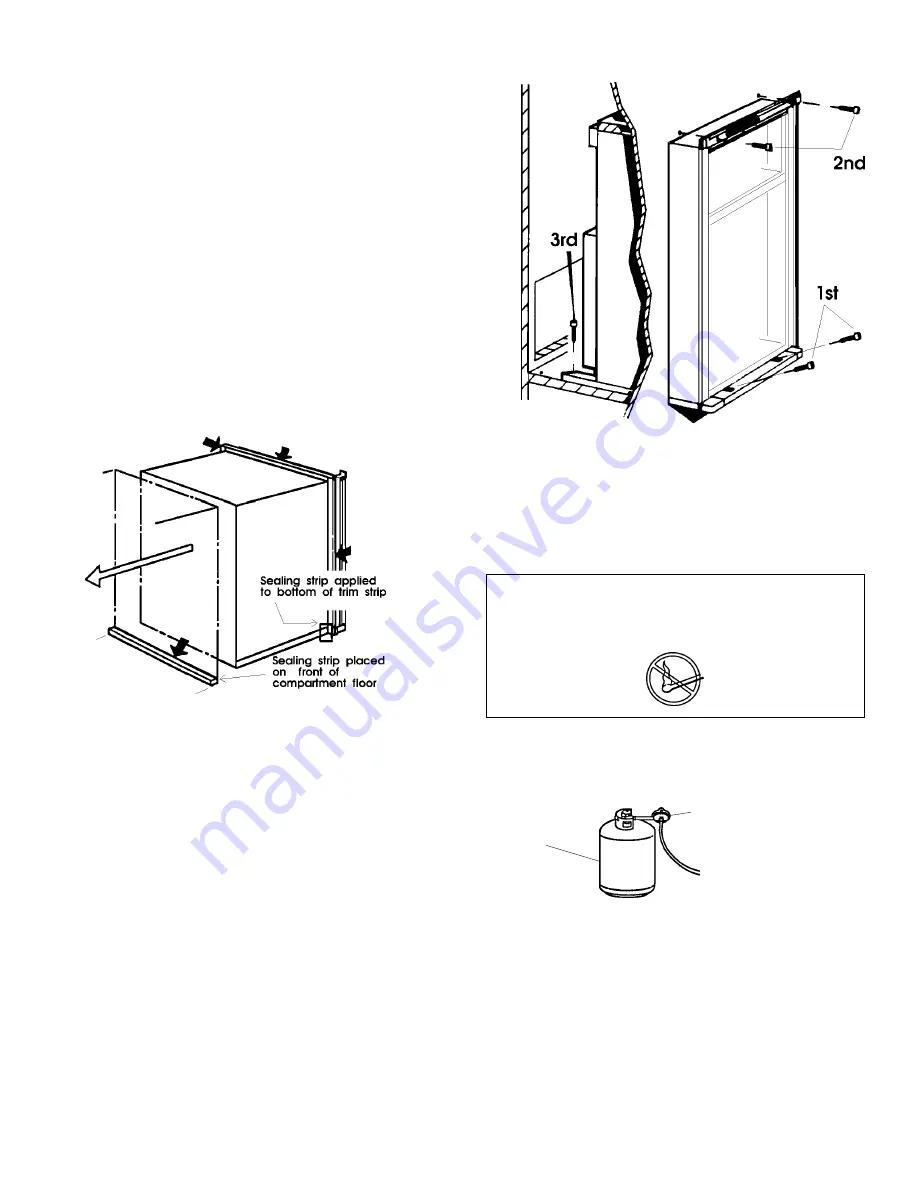

The refrigerator is secured in the enclosure with six screws

and they must be installed in the following order:

First Two Screws installed on front base;

Second Two Screws installed in the top frame;

Third Two Screws installed in the rear base.

Failure to follow the sequence in securing refrigerator in

enclosure can cause leakage between the frame and cabi-

net. The plastic caps are snapped in the front base to cover

the screw heads and the decoration strip is secured to top

frame. (See FIG. 5). Any space between the counter storage

area or ceiling and top of the refrigerator should be blocked.

The heat produced at the rear of the refrigerator will become

trapped in this space, making the top of the refrigerator hot

and reduce the efficiency of the refrigerator.

FIG. 4

FIG. 5

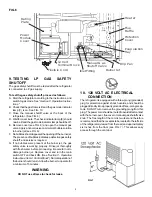

8. GAS CONNECTION

Hook up to the gas supply line is accomplished at the manual

gas shutoff valve, which is furnished with a 3/8" SAE (UNF

5/8" – 18) male flare connection. All completed connections

should be checked for leaks with a noncorrosive leak

detector. (See FIG. 6 – Gas tubing may have a different

orientation than shown).

WARNING

DO NOT USE A FLAME

TO CHECK FOR GAS LEAKS.

The gas supply system must incorporate a pressure regu-

lator to maintain a supply pressure of not more than 13-1/2

inches water column, (static) no load.

When testing the gas supply system at test pressures in

excess of 1/2 psig, the refrigerator and its individual shutoff

valve must be disconnected from the gas supply piping

system.

When testing the gas supply system at pressures less than

or equal to 1/2 psig, the appliance must be isolated from the

gas supply piping by closing its individual manual shutoff

valve.

In case detailed instructions on the installation and connec-

tion to the gas supply are required, contact your dealer or

distributor.

PRESSURE

REGULATOR

LP GAS

CYLINDER

T O

REFRIGERATOR