23

9.1 Internal Wiring

Check all wires and the connectors to ensure a proper

and tight connection. Also verify the refrigerator is wired

per the wiring diagram for the model you are working on.

(See applicable wiring diagrams for your model refrigera-

tor) A loose connection can create erratic operation. Al-

ways check the wires at the DC terminal block, two wires

in and two wires out.

SectIon 9 WIrIng

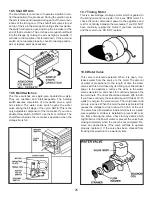

9.2 external Wiring

120 Volts ac connection:

The refrigerator is equipped

with a three prong (grounded) plug for protection against

shock hazards and should be plugged directly into a prop-

erly grounded three prong receptacle. DO NOT cut or re-

move the grounding prong from this plug.

12 Volt connection:

The connection is made to the ter-

minal block marked 12 volts DC. The control system is

connected to a battery/converter circuit and could draw

up to 3 amps at 12 volts DC. The refrigerator must be

connected to the battery circuit with two wires of adequate

capacity to avoid voltage drop. Proper polarity is crucial

for refrigerator operation. Don’t use the chassis for the

ground circuit.

A loose connection will create erratic op-

eration on gas and AC. The wires must be a dedicated cir-

cuit.

no other electrical equipment or lighting should

be connected to refrigerator circuit.

9.3 Wiring Schematics

To view typical wiring schematics look in the Lower Circuit

board testing section 5, page 14. All units should have a

specific schematic on the rear of that unit. To acquire the

proper one always have the product number when you

call or e-mail.

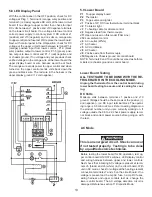

SectIon 10 error codes

The codes are displayed flashing ( alternating between

temperature and message) on the display.

No communication between display and power modules.

The control system will revert to full automatic operation

selecting the best energy source available with AC, GAS

priority. The temperature setting will be maintained at the

mid positions. The power module will continually attempt

to reestablish operation of the display module. Test Cable,

Upper LED display panel, Lower board, clean all grounds,

and try a different DC power source. If problem still exist

change lower control board.

e 0

e 1

Hardware fault in the gas operation system.

Test Upper and lower controls, Solenoid, wire harness,

clean all grounds and try a different DC power source.

A failure of the temperature sensor device or associated

electronic circuitry has occurred. If the connection to the

temperature sensor is faulty, the cooling unit runs continu-

ously ( over cool ) after 30 seconds delay at power on.

Test Thermistor.

SectIon 11 diagnostic mode

To perform a diagnostic test:

1.

Turn off the refrigerator. (press ON/OFF button)

2.

Press and hold the TEMP. SET button and then,

press the ON/OFF button.

3.

Release the TEMP. SET button. Press it again to

toggle the list of functions step by step.

e 2

1 All outputs off F

E 0 Communication Fault

E 2 Temperature sensor fault

2 Turn LAC

heater on

L H E 0 Communication Fault

0 N LAC heater on

Press the lamp switch. The

lamp should still be on.

3 Turn AC heat-

er on

A C E 0 Communication Fault

0 N AC heater on

“ ” AC heater off, AC not

available

4 D+ status (if

D+ is con-

nected) Not

available on

all models

d P E 0 Communication Fault

0 N D+ high

“ ” D+ low

5 Run gas (one

attemp only)

L P E 0 Communication Fault

E 1 Igniter & valve off, gas

hardware fault

0 N Igniter & valve on

F L Igniter off &valve on flame

detected

“ ” Igniter & valve off, gas

problem (check gas) ( If

flame is not ignited within

45 seconds)

number

test function

test Indication

test results Indication

11.1 diagnostic test

Summary of Contents for RM3962

Page 15: ...14 RM3762 RM3962...

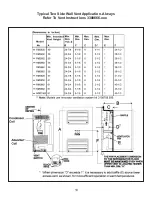

Page 20: ...19 Typical Two Side Wall Vent Application Always Refer To Vent Instructions 3308666 xxx...

Page 23: ...22...

Page 28: ...27...

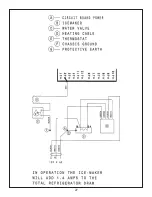

Page 29: ...28 ICE MAKER TYPICAL WIRING DIAGRAM...

Page 33: ...32...