INSTALLATION

GENERAL INSTRUCTIONS

The refrigerators outlined hereon have been design certified

under ANS Z21.19b

- 1982. Refrigerators by the American Gas

Association for installation in a mobile

home or recreational vehi-

cle and are approved by the Canadian Gas Association.

The certifications are, however, contingent on the installation

being made in accordance with the following instructions as

applicable.

The lnstallation must In the USA conform with:

1. National

Fuel Gas Code Z223. H 980

2. Mobile Homes ANSI/NFPA No. 501 B-1977

3. Recreational Vehicles ANSI/NFPA No. 501 C-1977

The unit must be electrically grounded in accordance with the

National Electric Code ANSI/NFPA No. 70-1981 when installed if

an external alternating current electrical source is utilized.

4. Any applicable local code

In Canada

1. Standard CGA 10.0-CSA 2240.4, gas equipped mobile hous-

ing and recreational vehicles

2. Standard CSA Z240.6.1 electrical requirements for mobile

housing

3. Standard CSA Z240.6.2/C22.2 No 148 electrical require-

ments for recreational vehicles.

Thls appliance is designed for storage of foods and storage

of frozen foods and making ice.

Note. Do not install the appliance directly on carpeting. Car-

peting must be protected by a metal or wood panel beneath

the appliance which extends at least full width and depth of

the appliance.

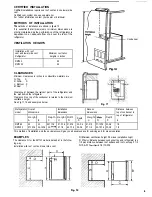

Ventilation

The installation shall be made in such a manner as to separate

the combustion system from the living space of the mobile home

or recreational vehicle. Openings for air supply or for venting of

combustion products shall have a minimum dimension of not

less than 1/4 Inch.

Proper installation requires one lower fresh air intake and one

upper exhaust vent. The ventilation kits shown in this instruction

booklet have been certified for use with the refrigerator models

listen in the tables. Certified vent system kits, see separate

Ilst. The ventilation kits must be installed and used without modi-

fication. An opening towards the outside at floor level in the

refrigerator compartment must be provided for ventilation of

heavier-than-air fuel gases. The lower vent of the recommended

kits is provided with proper size openings. The flow of combus-

tion and ventilating air must not be obstructed.

For ready serviceability of the burner and control manifold parts

of the refrigerator the lower side vent is fitted with a liftout p a n e l

which provides an adequate access opening.

GAS CONNECTION

Hook-up to the gas supply line is accomplished at the manual

gas valve, which

IS

furnished with a 3/8” SAE (UNF 5/8”- 18) male

flare connection. All completed connections should be checked

for leaks with soapy water.

The gas supply system must incorporate a pressure regulator to

maintain a supply pressure of not more than

11

Inches water

gage.

In case detailed instructions on the installation and connection to

the gas supply are required. contact your dealer or distributor.

ELECTRICAL CONNECTION

120VOLTSAC

The

refrigerator is equipped with a three prong (grounded) plug

for protection against shock hazards and should be plugged

directly into a properly grounded three prong receptacle. Do not

cut or remove the grounding prong from this plug. The cord

should be routed to avoid coming in contact with the burner

cover, flue cover or other hot components.

12V DC

THREE WAY CONNECTION

The

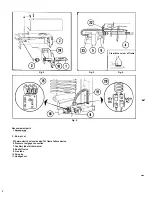

connection is to be made to a terminal block 15, see fig 5.

The refrigerator must be connected to the battery circuit with two

wires of adequate capacity to avoid voltage drop. The wire gage

should be chosen with consideration to the wire length in accord-

ance with table below. The 12 V circuit must be fused. Maximum

circuit fuse size: 30 Amps for RM763 and 40 Amps for RM1303.

Do not use the body or chassis of the vehicle as a substitute for

either of the two conductors. No other electrical equipment or

lighting should be connected lo the refrigerator circuit. The

refrigerator will draw from 20 to 23 Amps at 12 Volt depending on

model.

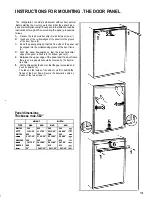

Suggested maximum two conductor wire length in feet

AWG RM763

RM1303

10 13

6 22

19

6 34 31

4 55 50

12 V power operation

When power operation from the alternator is desired a low cur-

rent, positive, 12V DC signal shall be given into the control sys-

tem. A connection has to be made

between the ignition system

of the engine and the block marked IGN LOCK on the back of the

fridge, see fig 5. Examples of circul diagrams are shown in fig 6

and 7.

If the connection to the ignition system is not made the

refrigerator will not operate on 12 V power, i.e. gas will be used

whenever 120 V is not available.

12VDC

TWO WAY CONNECTION

When the refrigerator is not to be operated on 12 V power do not

connect to ignition lock (delete the 16-ga wire in the exemples).

Use minimum 14-ga wire between the battery and the

refrigerator for the control voltage (connection points 12 V + and

- in fig. 5, part 15. Leave IGN LOCK key open). In this case the

maximum fuse size shall be 4 Amps instead of the fuse sizes

mentioned above.

Caution

It is necessary with a battery in the 12 Volt circuit. The operation

of the 12 Volt control system can be disturbed if it is powered by a

converter only.

4

Summary of Contents for RM663 and

Page 2: ...0 10 Fig 1 0 1 ...