30

DOMETIC® RM7030/RM7732

Refrigerators

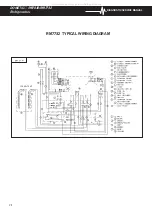

DIAGNOSTIC SERVICE MANUAL

11.4 SHUTOFF ARM

The shutoff arm is cam driven. It operates a switch to

control the quantity of ice produced. During the ejection

cycle the arm is raised and lowered during each of the

two revolutions of the timing cam. If the shutoff arm

comes to rest on top of the ice in the storage bin during

either revolution, the switch will remain open and stop

the ice maker at the end of that revolution. The arm has

a manual shutoff built into the linkage; by raising the

arm as high as possible, it will lock in that position until

forced down.

If the arm and switch do not operate properly, check for

damage and repair or replace parts as necessary.

11.5 MOLD SWITCHES

These three switches are single-pole, double-throw

style. They are identical and interchangeable.

The holding switch

assures completion of a revolution

once a cycle has started.

The water valve switch

opens the water valve during

the fill stage of the cycle. NOTE: This is the only adjust-

able component of the ice maker. If you use a double-

throw switch, DO NOT use the N.O. terminal.

The shutoff switch

stops the ice maker's operation

when the storage bin is full.

ARM DOWN

ICE MAKER

WILL OPERATE

ARM UP

STOPS

OPERATION

Shutoff

SWITCH

LEVER

ARM

FRONT VIEW

MOTOR

MOUNTING

PLATE

TIMING CAM

WATER

VALVE

SWITCH

HOLDING

SWITCH

11.6 TIMING MOTOR

This is a low-wattage, stall-type motor which is geared

to the timing cam and ice ejector. It is a one RPM

motor.

To check the motor, disconnect power to the appliance

and test for continuity between the two leads. If you DO

NOT have continuity, replace the motor. If you have

continuity and the motor runs, DO NOT replace.

11.7 WATER VALVE

This valve is solenoid operated. When it is open, it

releases water from the source to the mold. The amount

of water is proportional to the length of time the water

valve switch is held closed by its timing cam.

Disconnect power to the appliance, remove the wires to

the water valve solenoid coil, and check for continuity

between the two terminals. If you have continuity, the

solenoid is good. It takes 10-15 watts to energize the

solenoid coil. The mold heater and coil are in series.

When the mold heater is activated, this causes the

voltage to drop to about 105 VAC at the coil.

The valve has a flow washer inside which acts as a

pressure regulator. A strainer is installed to prevent dirt,

rust, etc. from entering the valve. Check for any debris

which might obstruct the flow of water, or prevent the

valve from closing completely when the circuit is not

energized. Remove any obstructions. If the valve still

fails to operate properly, replace it.

VALVE BODY

WATER VALVE

STRAINER

FLOW

WASHER

SOLENOID

COIL

All manuals and user guides at all-guides.com