35

DIAGNOSTIC SERVICE MANUAL

DOMETIC® RM7030/RM7732

Refrigerators

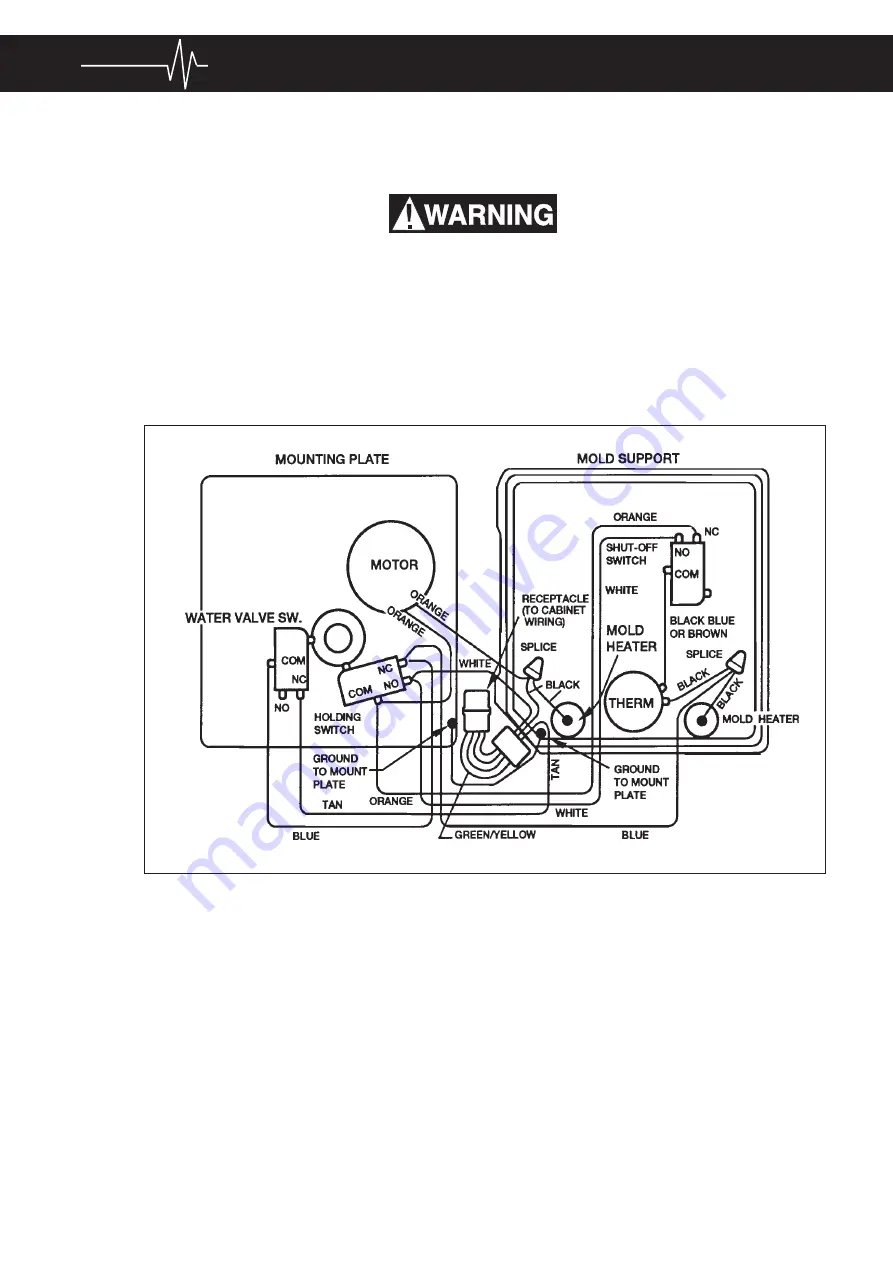

12.2 WIRING

Refer to the wiring diagram supplied with the unit you are working on, and make sure all wiring connections are

correct and tight.

THIS IS AN ENERGIZED CIRCUIT. ELECTRICAL SHOCK CAN OCCUR.

BEFORE CHECKING THESE COMPONENTS BE SURE THERE IS NO POWER TO THE APPLIANCE.

ICE MAKER TYPICAL WIRING DIAGRAM

12.3 WATER SUPPLY

To operate properly, the water pressure in the water

supply line must be between 15 lbs. PSI and 125 lbs.

PSI.

Lower water pressure, water turned off, or obstructions

or air in the water line can cause low or no ice produc-

tion.

First check to see that the water supply is fully turned

on. Visually check the line for kinks, etc. which might

obstruct the flow of water.

To remove trapped air, loosen the connection at the

water solenoid valve of the appliance. Ensure that

pressurized water is reaching this point, and bleed off

any air in the line. Retighten the connection, making

sure there are no leaks.

All manuals and user guides at all-guides.com