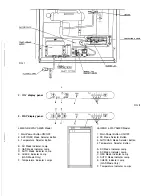

FIG. 16

GAS EQUIPMENT ASSEMBLY

PRESSURE TEST PORT

ELECTRlC EQUIPMENT

CARTRIDGE HEATER

The heat necessary for the operation of an absorption

cooling unit is supplied by an electric heater mounted in

a pocket of the boiler system.

The 3-WAY Model is equipped with two electrical

heaters, one for 120 volt AC and one for 12 volt DC.

The 2-WAY Model is equipped with one electric heater

120 volt AC.

To replace the heater proceed as follows:

1. Disconnect the wall plug, and the 12 volt wires.

2. Remove the protection cover see FIG. 1

3. Remove the pover module cover see FIG. 1

4. Disconnect the heater leads.

5. With a pair of pliers unfold the lug holding the lid of

the boiler casing and open the lid.

6. Remove some insulation wool so that the heater is

accessible.

7. Turn and lift the heater out of its pocket.

8. Fit the new heater into the pocket.

9. Connect the leads and put on the power module

cover.

10. Reset the insulation and close the lid of the boiler.

11. Replace the protection cover.

FUSES

The 2-way AMES models are equipped with 2 fuses, one

for the refrigerator control system and one for the AC

cartridge heater.

The 3-way AMES models are equipped with a third fuse

for the DC cartridge heater. (see table below)

To replace fuse(s) proceed as follows.

1.

Disconnect the wall plug, and the 12 volt wires.

2. Remove the power module cover. See FIG. 1.

3. Snap the fuse out of the fuse holder.

4. Fit a new fuse in to the fuse holder.

5. Replace the power module cover.

1.

2.

A.

MAINTENANCE & SERVICE

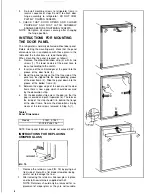

REFRIGERATOR REMOVAL

Before working on the refrigerator make sure that

120 volt AC and 12 volt DC leads are disconnected.

Close the shutoff valve on the gas supply piping sys-

tem. Disconnect the outgoing gas line from the gas

valve at the rear of the refrigerator. (see FIG. 1.)

Loosen the screws anchoring the refrigerator to the

enclosure and slide the refrigerator forward out of

the compartment.

When replacing the refrigerator make sure that the

sealing strips are properly positioned.

After ressemble the gas connection should be

checked for leaks.

PERIODIC MAINTENANCE

To keep your Silhouette refrigerator operating effi-

ciently and safely, periodic inspection and cleaning

of several components once or twice a year is

recommended.

It is important to keep the area at the back of the

refrigerator clean. Check the lower vent, upper vent

and area between these openings for any obstruc-

tions such as bird/insect nests, spider webs, etc.

Clean the coils on the back of the refrigerator. Use

a soft bristled brush to dust off the coils.

It is important to keep the refrigerator area free from

combustible material, gasoline and other flammable

vapors or liquids.

NOTE: AVOID SPRAYING WATER THROUGH

THE REFRIGERATOR VENTS WHILE WASHING

YOUR RV.

Clear blue coiour of flame

FIG. 17

13

Summary of Contents for Silhouette S1521

Page 14: ......