5

Installation

inches for air entry and discharge.) A lower entry, and

upper discharge is preferred. See Ventilation Requirements

diagram in this manual.

Install appliance away from heat sources in a dry and well-

ventilated area. Avoid direct contact with water.

The

appliances are not waterproof.

Electrical Connection

Before connecting the appliance to the power supply, check

that the line voltage corresponds to the indications on the

appliance rating plate and those of the compressor plate.

This appliance complies with EC directive 89/336 governing

radio suppression.

DC Wiring

For Direct Current (DC) refrigerators, connect the appliance

to the DC distribution center. A circuit breaker of 15 Amps

(maximum) must be used if the system is 12VDC, and 10

Amps (maximum) if the system is 24VDC.

Make sure that

proper polarity is maintained at all times.

Check that all

grounding systems are in good working order.

The appli-

ance must be wired and grounded in accordance with

the Electrical Wiring Guidelines in this manual.

DANFOSS Compressor Data

Voltage Range

12V systems: From 10.4V to 17V

24V systems: From 22.8V to 31.5V

The electronic unit will calibrate automatically to the applied

voltage. This means that if the battery voltage is less than

17V, the electronic unit assumes that it is working in a 12V

system. If the voltage is higher than 17V, the electronic unit

assumes that it is working in a 24V system. However, the

compressor does not run at power supply voltages between

about 17V and 22.8V, the desired battery protection cut-out

voltage for 24V systems.

Protection Systems

The Danfoss compressor protection system facilitates

protection against compressor overload and start failure,

fan overload and electronic unit overheating as well as

destructive battery discharge. When an overload protection

is activated, the compressor enters a cycle in which it

makes start attempts at approximately 60 second intervals

until a successful start is achieved.

Overload Protections

The compressor overload and start protection cuts off

power to the compressor if the compressor speed drops

below approximately 1,900 rpm, or if this motor speed is

not reached during the start sequence. Possible reasons for

overload protection activating could be too high refrigera-

tion system pressures during operation or lack of pressure

equalizing at start.

The fan overload protection stops the compressor if the fan

current exceeds 0.5 A

(avg)

or 1 A

(peak)

.

An overheating of the electronic unit heat sink will cause

the compressor to stop. Restart will occur automatically

when a normal temperature has been reached. If a fan is

installed, it will continue to run when the compressor stops

due to overload or electronic unit overheating.

Voltage Protection

If a voltage outside any concerned range is applied to the

electronic unit, the compressor does not start, or it stops if

the voltage limit is exceeded during operation. The com-

pressor will restart automatically approximately 1 minute

after the supply voltage has reached the reset voltage

within the range in question.

Battery Protection

The Danfoss electronic unit provides protection as follows:

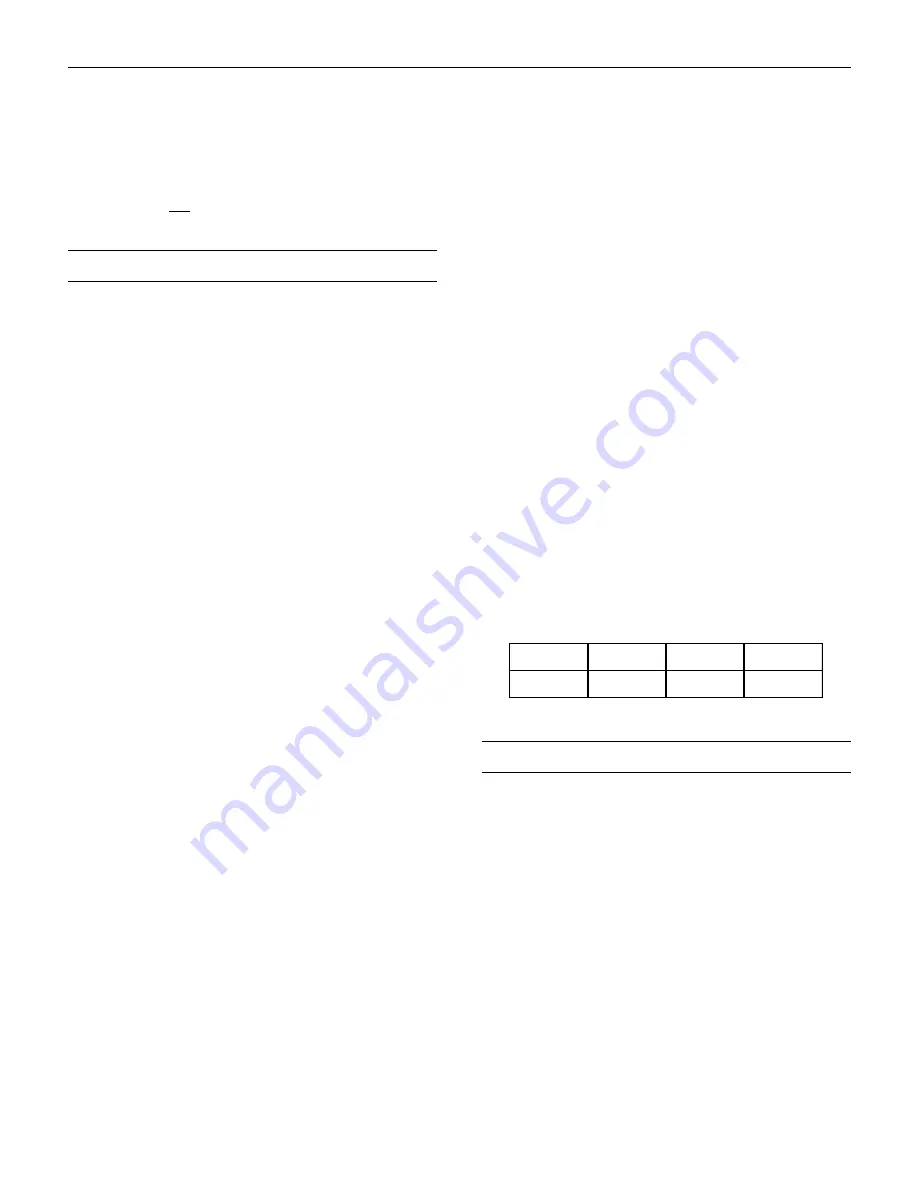

Standard Battery Protection Settings

12V cut-out

12V cut-in

24V cut-out

24V cut-in

10.4

11.7

22.8

24.2

Final Installation Notes

• For all appliances, AVOID the use of any electrical

adapters or extension cords.

• After installation, allow the appliance to sit for at least

one hour before starting.

•

The manufacturer assumes no responsibility for any

injuries or damage caused by noncompliance with

any of the installation regulations.