EN

15

3 Servicing

The recommended Service procedures identified in table 3.2 and all other repair and calibration work should be undertaken by a domnick

hunter trained, qualified and approved engineer.

3.1 Cleaning

Clean the equipment with a damp cloth only and avoid excessive moisture around any electrical sockets. If required you may use a

mild detergent, however do not use abrasives or solvents as they may damage the warning labels on the equipment.

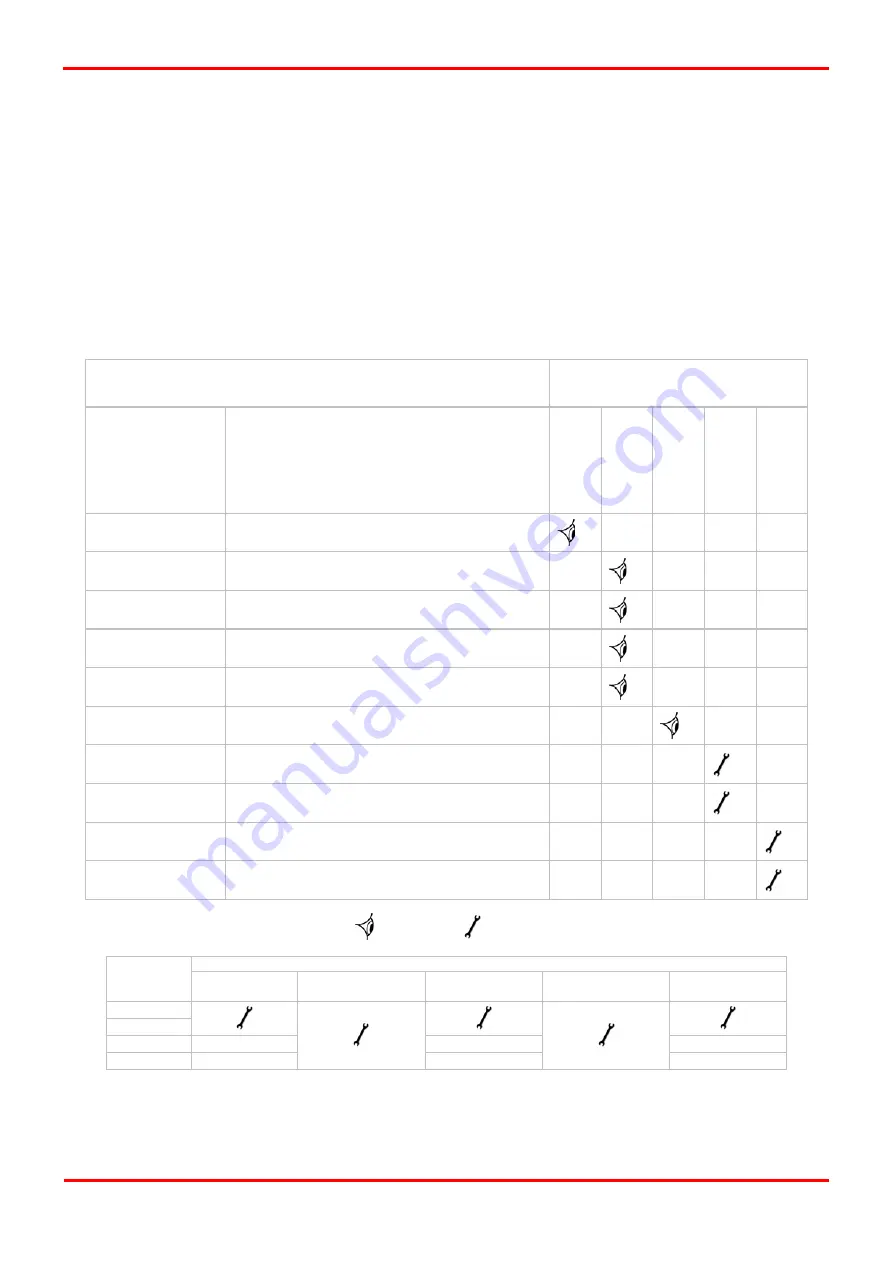

3.2 Service Intervals

Description Of Maintenance Required

Typical Recommended Maintenance

Interval

Component Operation

Daily

2000 Ho

urs

(3-m

on

th

)

4000 Ho

urs

(6-m

on

th

)

80000 H

ours

(12-

mo

nth

)

16000 H

ours

(24-

mo

nth

)

Generator

Check status indicators located on the control panel.

System

Check inlet air quality

Generator

Check for air leaks

Generator

Check pressure gauges during purging for excessive

back pressure

Generator

Check condition of electrical supply cables and conduits

Generator

Check cyclic operation

Generator

Replace active exhaust silencers

Recommended Service A

Filtration

Replace dust and control air filters.

Recommended Service B

Generator

Replace/Calibrate oxygen sensor

Recommended Service C

Generator

Replace/Service valves

Recommended Service D

- Check

– Replace

Typical Recommended Maintenance Intervals

Service

8 000 Hours

(12 Months)

16 000 Hours

(24 Months)

24 000 Hours

(36 Months)

32 000 Hours

(48 Months)

40 000 Hours

(60 Months)

A

B

C

D

domnick hunter ltd and its distributors offer a comprehensive range of preventative maintenance programmes, for further details

contact your local domnick hunter distributor or domnick hunter ltd direct (tel. 44 (0)191 402 9000) for further details.

Summary of Contents for Maxigas 104

Page 1: ...104 120 SERVICE GUIDE ...

Page 2: ......

Page 4: ......

Page 8: ......

Page 10: ...10 Menu Map ...

Page 11: ...11 ...

Page 14: ......

Page 30: ......

Page 32: ......

Page 33: ...EN 33 APPENDIX A SCHEMATICS ...

Page 34: ......

Page 35: ......