EN

29

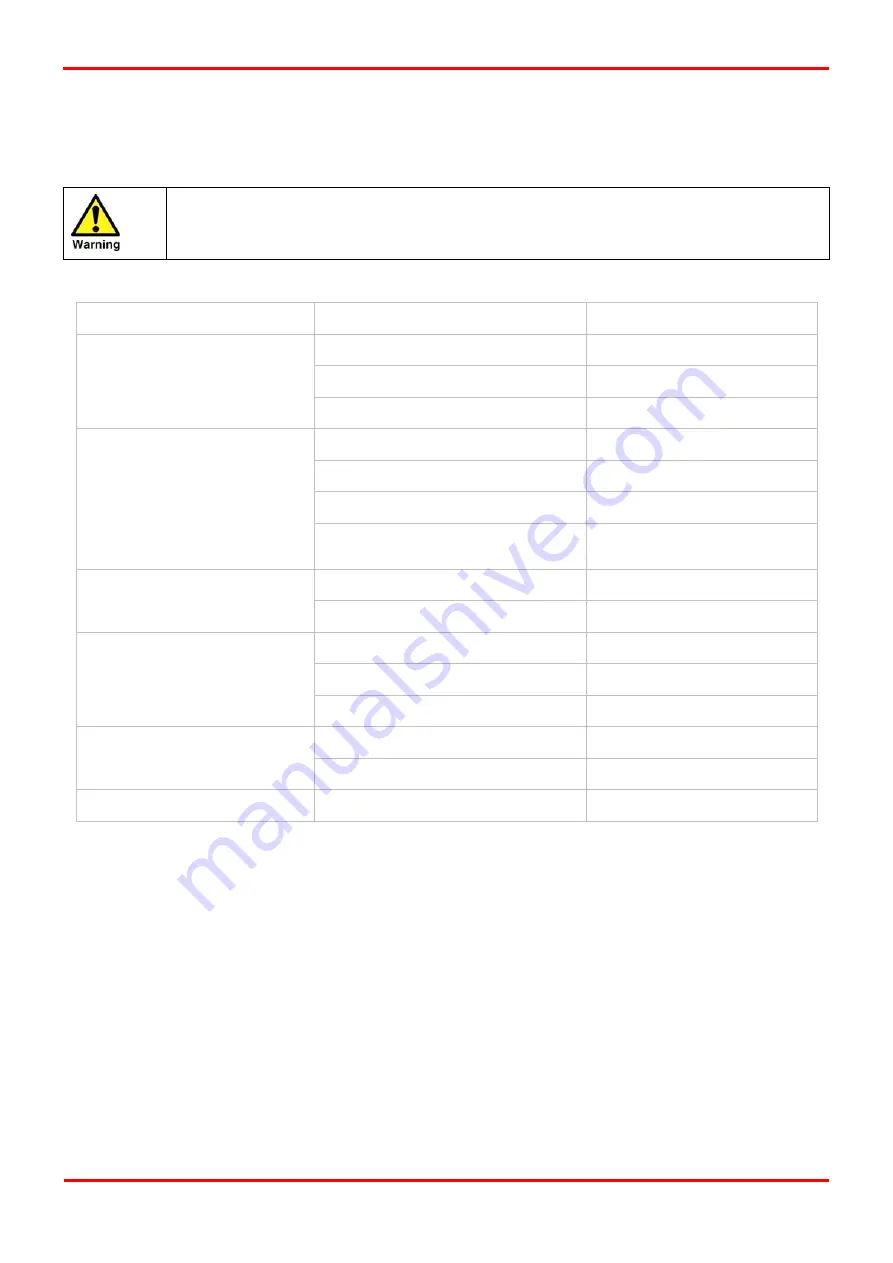

5 Troubleshooting

In the unlikely event that a problem occurs on the equipment, this troubleshooting guide can be used to identify the probable cause and remedy.

Troubleshooting should only be attempted by competent personnel. All major repair, and calibration work should be

undertaken by a domnick hunter trained, qualified and approved engineer.

Fault Probable

Cause

Remedy

Fuse Blown

Replace Fuse

Ribbon cable disconnected

Reconnect Ribbon cable

Power Connected but LCD and status

indicators not illuminated.

Power disconnected

Reconnect Power

Service Overdue

Service the generator

Internal gas leak

Check and Rectify

External gas leak

Check and Rectify

No / Low gas outlet pressure

Low inlet pressure

Ensure pressure meets required

specification

Defective Oxygen cell.

Replace.

High Oxygen concentration.

Leak in system piping.

Check and Rectify

Compressor or ring main pressure low.

Check and Rectify

Inlet valve not open

Check and Rectify

Low inlet pressure

Defect on pre-treatment package.

Refer to pre-treatment manual.

Silencer loose or defective.

Check and Rectify

Excessive noise or vibration

Solenoid valve wear or coil loose.

Check and replace if required.

High outlet pressure.

Outlet regulator defective.

Reset or replace.

Summary of Contents for Maxigas 104

Page 1: ...104 120 SERVICE GUIDE ...

Page 2: ......

Page 4: ......

Page 8: ......

Page 10: ...10 Menu Map ...

Page 11: ...11 ...

Page 14: ......

Page 30: ......

Page 32: ......

Page 33: ...EN 33 APPENDIX A SCHEMATICS ...

Page 34: ......

Page 35: ......