19

8.2

Boiler maintenance:

Various maintenance operations should be carried out at different intervals to keep the boiler in

perfect working order.

The most important aspects to be checked are as follows:

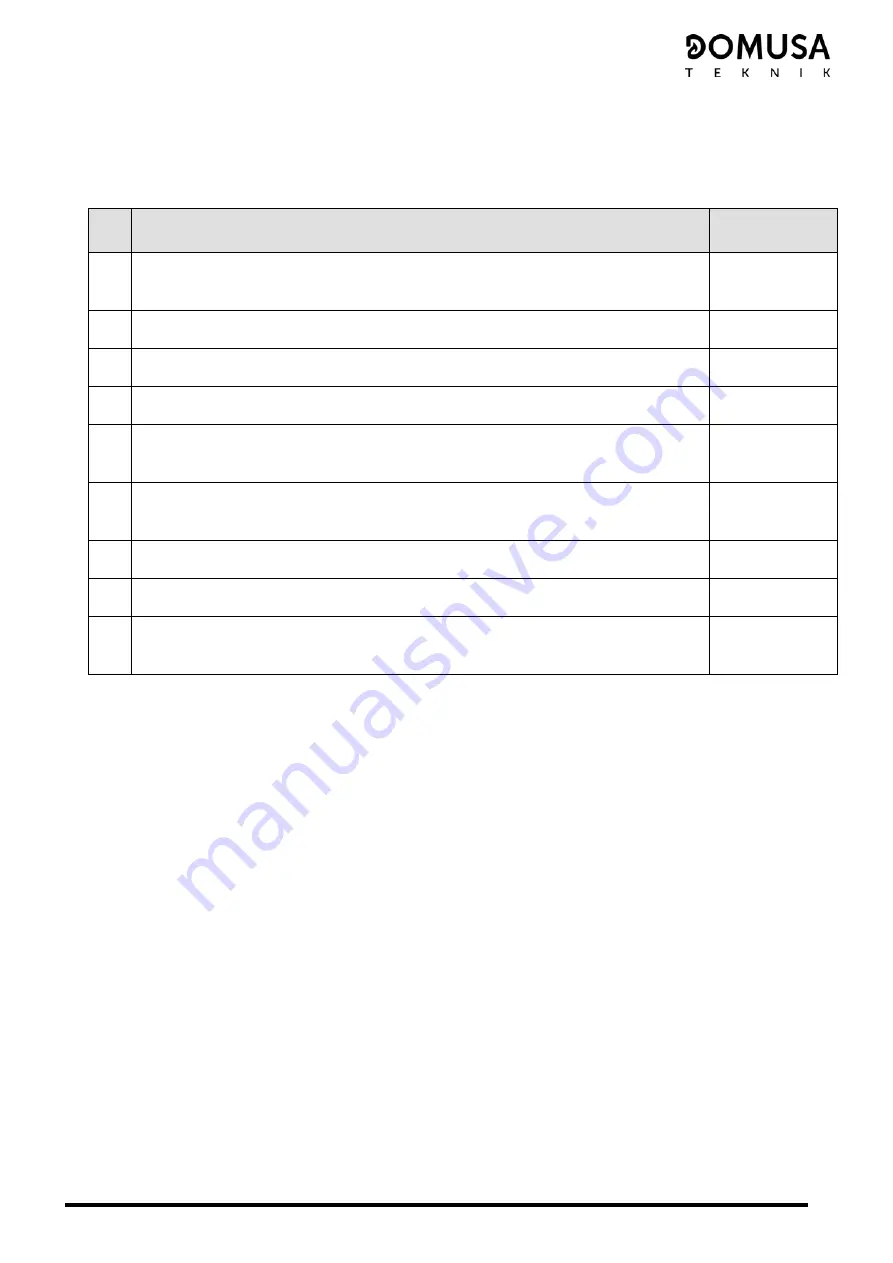

No. Operation

Frequency

1. Clean ashes from the loading compartment, combustion chamber and

flue.

3-5 loads of

firewood

2. Check the boiler visually.

weekly

3. Clean tar from the loading compartment

monthly

4. Clean the windows of the peep-holes with alcohol

visual control

5. Clean all exchange surfaces: flue, fume chamber, etc. You can use the

cleaning brush for scraping and descaling any embedded tar or ashes.

yearly

6. Check and clean the flue. The flue must be free of any obstacles and have

no leaks.

yearly

7. Check the expansion vessel. It must be full, according to its reference plate.

yearly

8. Check the air-tightness of the housing doors.

yearly

9. Check the water pressure in the heating installation.

In cool mode

, it

should be between 1 - 1.5 bars.

yearly

8.2.1

Draining the condensation water

Draining of condensation water from the flue should not be altered in any way and it must be

kept free of obstructions.

8.2.2

Boiler water characteristics

In areas with water hardness exceeding 25-30ºfH, treated water must be used in the heating

installation to avoid any scale deposits on the boiler. It should be noted that even a few

millimetres of lime-scale will greatly reduce the boiler's heat conductivity, causing a significant

decrease in its performance.

Treated water must be used in the heating circuit in the following cases:

- Very large circuits (containing a large amount of water).

- Frequent filling of the installation.

If repeated partial or total draining of the installation is necessary, we recommend filling it with

treated water.

Summary of Contents for LIGNUM NG 20

Page 1: ...INSTALLATION AND OPERATING INSTRUCTIONS LIGNUM NG ...

Page 36: ...Lignum NG 34 Outside ...

Page 42: ...Lignum NG 40 NOTES ...

Page 43: ...41 NOTES ...