5

- Leave a free space around the boiler for carrying out any maintenance and repair operations.

- Drain valves and suitable devices for correctly bleeding the air from the circuit during the boiler

filling stage should be fitted.

- Install all the necessary safety elements (expansion vessel, safety valve, etc.) to comply with the

applicable regulations for the installation.

3.3

Fuel: preparing the firewood

Firewood is the fuel which must be used for the

Lignum NG

boiler. If this requirement is not

complied with,

DOMUSA TEKNIK

's guarantee of the appliance will automatically be null and void.

The quality of the fuel plays an important part in the performance and useful life of the boiler. The

firewood must have less than 20% water content (humidity). If the percentage of water is too high,

the corrosion inside the boiler increases and the boiler performance is drastically reduced.

"Green" wood (recently cut) may contain over 50% humidity. Its caloric power is approximately half

of that of "seasoned" wood with 15% humidity. The greater the humidity of the wood, the slower

the combustion and the lower the flame temperature. This abruptly increases the amount of soot

and tar in the fumes.

To reach dry levels in the air (<20%), the following drying times are recommended:

-

Oak:

2.5

years

- Beech, ash, fruit trees:

2 years

- Linden, alder, birch:

1.5 years

- Pine, poplar, spruce:

1 year

If the wood is not cut (round wood), a minimum of 2 extra months are required.

In addition to the cutting, another important factor is the physical size of the firewood. In relation

to its mass, smaller firewood has a greater surface than larger pieces of wood. It is easier to ignite

and its combustion is quicker. Large firewood may slow down combustion due to an unfavourable

volume/surface area ratio. This, unavoidably, implies a lower flame temperature and greater

contaminant emissions.

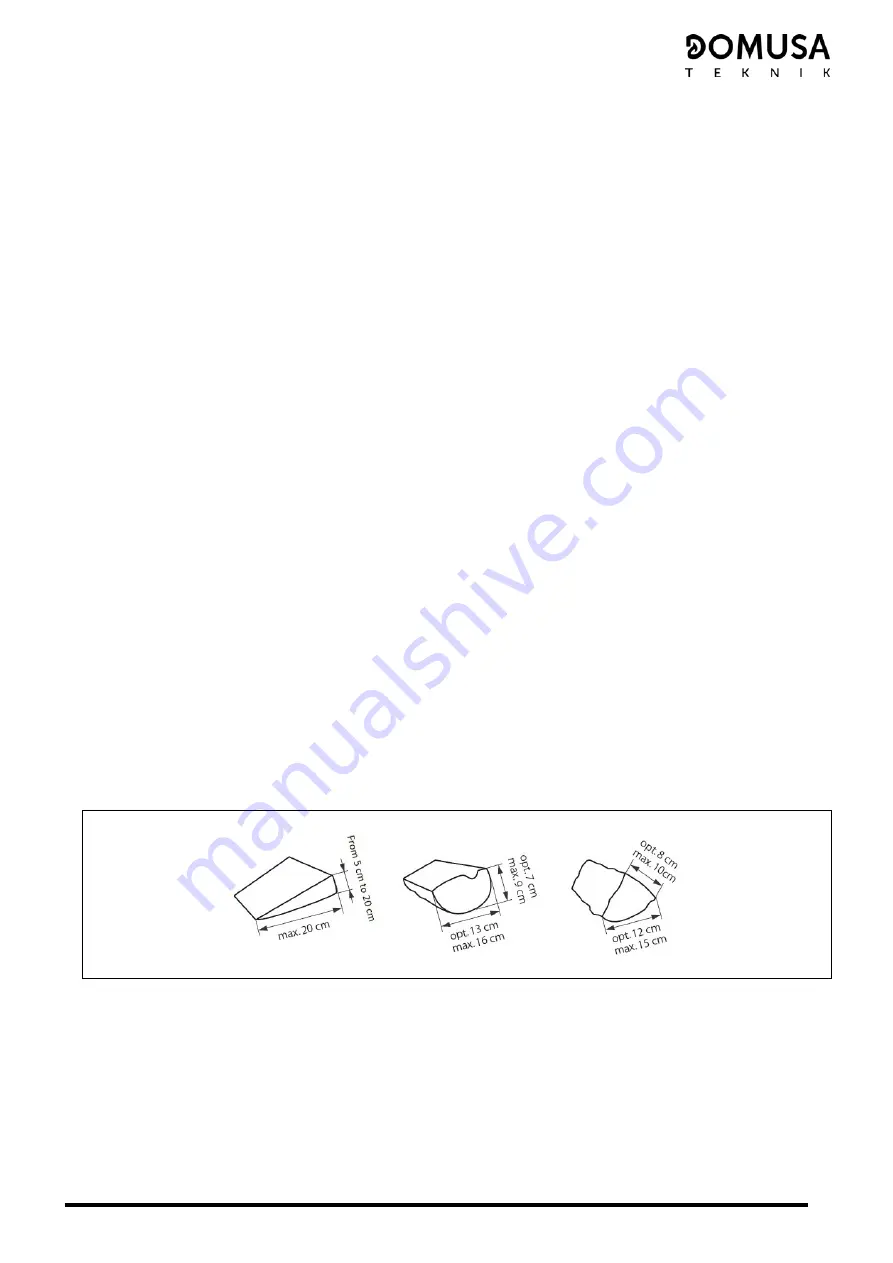

The following sizes of firewood are those recommended for a perfect and homogeneous service in

the combustion chamber:

For Lignum NG 20, Lignum NG 30 and Lignum NG 40 boilers, the recommended log length is 50

cm. If the logs are short, it is recommended that they be placed lengthwise in the back part and

that the free space at the front be filled with logs placed obliquely.

Summary of Contents for LIGNUM NG 20

Page 1: ...INSTALLATION AND OPERATING INSTRUCTIONS LIGNUM NG ...

Page 36: ...Lignum NG 34 Outside ...

Page 42: ...Lignum NG 40 NOTES ...

Page 43: ...41 NOTES ...