Downflo II, Models DFT 2-4 and DFT 3-6

15

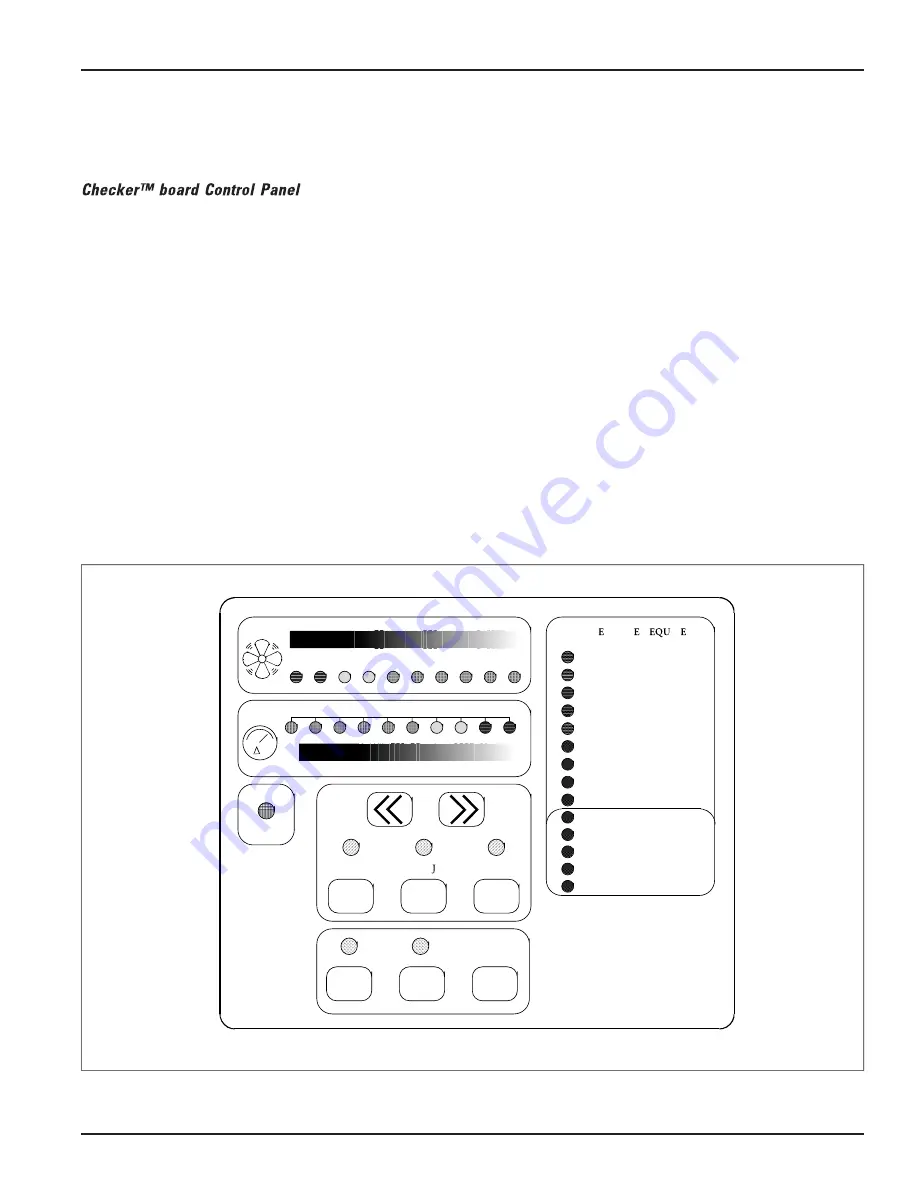

The Checker board provides cleaning control,

diagnostic review of the operational parameters,

diagnostic review of the system components, and a

record of operational data and fault conditions for

future review. The operator interface provides

control of unit functions and operational status

information.

The design allows a host computer to remotely

control the unit, accept change to operational

parameters, and check operational status.

1. Mount the control enclosure in a convenient,

accessible location that provides the best visual

advantage. Mount the enclosure to a wall or

column with little or no vibration and away

from static discharges that could damage

components.

2. Make the proper electrical and pneumatic

connections to the collector and motor starter

following the diagrams and instructions

supplied with the Checker board.

3. Verify proper blower rotation by pushing the

start-stop button ON then OFF. Rotation must

match the rotation arrow on the blower

housing as viewed from the top.

4. Calibrate the Checker board computer to the

system airflow. Establish filter cleaning settings

and service intervals.

Note:

See the Checker board Installation and

Operation Manual, IOM 7220601 for

complete installation and operating

instructions.

PANEL

STOP

CLEAN

START

CLEAN

SERVICE

INTERVAL

SET POINT AD USTMENT

CONSTANT

CLEAN

DOWN

TIME

CLEAN

SERVICE

INTERVAL

LIGHT

RESET

AIR FLOW

SET POINT INDICATOR

FILTER PRESSURE DROP

P

MAINT NANC R

IR D

PANEL

CLEANING FAILURE

FILTER RUPTURE

FILTER PLUGGED

TEMPERATURE

SERVICE INTERVAL

BLOWER OVERCURRENT

BLOWER ROTATION

COMPRESSED AIR

Checker board Control Panel