80

•

Engine Air Filtration

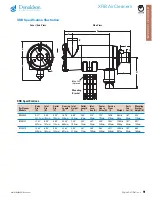

FKB Air Cleaners

MEDIUM DUST AIR CLEANERS

www.buydonaldson.com

The FKB series is a family of two-

stage air cleaners for medium dust

conditions.

Compared to other air cleaner

styles, this new air cleaner family

delivers the performance of

competitive larger air cleaners in

a compact, rugged design.

With heavy-duty plastic

construction and non-metal filters,

the air cleaner is lighter, more

efficient, and easier to install and

replace than competing products.

Another key design feature is the

built-in mounting brackets. There’s

no need for additional mounting

support.

The two-stage design features

a built-in pre-cleaner that

separates up to 85% of airborne

contaminants.

Smaller, Lightweight Alternative Two-Stage Air Cleaner

Designed for horizontal installation

The FKB’s plastic housing and

durable construction enables

installation in all types of operating

environments and temperature

ranges from -40 °C to 82 °C,

operating in medium-dust

conditions with engine air flow from

70 to 207 cfm (2 to 5.9 m3/min).

FKB05

FKB04

FKB06

FKB air cleaners effectively reduce

contaminants flowing into the air

intake system, provide a high level

of engine protection from harmful

contaminants and increase engine

performance and fuel efficiency.

The air cleaner models ship with

both the primary and safety filters.

Mann+Hummel

Donaldson FKB05

Cummins Filtration / Fleetguard

FKB air cleaners are smaller in diameter compared to competitive brands with similar airflow.

Cummins and Fleetguard are registered trademarks of Cummins Filtration, Inc.

Mann+Hummel is a registered trademark of Mann+Hummel GMBH