59

Donaldson Company, Inc.

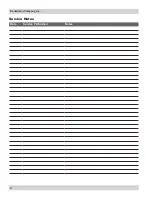

Optional Equipment

Magnehelic

®

Gauge

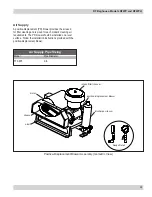

The Magnehelic is a differential pressure gauge used to

measure the pressure difference between the clean-air and

dirty-air plenums and provides a visual display of filter change

requirements. The high-pressure tap is located in the dirty-air

plenum and the low-pressure tap is located in the clean-air

plenum.

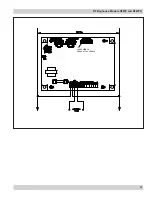

1. Choose a convenient, accessible location on or near

the collector for mounting that provides the best visual

advantage.

2. Plug the pressure ports on the back of the gauge using

two, 1/8-in NPT pipe plugs supplied. Install two, 1/8-in

NPT male adapters supplied with the gauge into the high-

and low-pressure ports on the side of the gauges.

3. Attach the mounting bracket using three, #6-32 x 1/4-in

screws supplied.

4. Mount the gauge and bracket assembly to the supporting

structure using two, self-drilling screws.

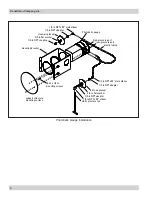

5. Thirty-five feet of plastic tubing is supplied and must be

cut in two sections. Connect one section of tubing from the

gauge’s high-pressure port to the pressure fitting located

in the dirty-air plenum. Connect remaining tubing from

the gauge’s low-pressure port to the fitting in the clean-

air plenum. Additional tubing can be ordered from your

representative.

6. Zero and maintain the gauge as directed in the

manufacturer’s Operating and Maintenance Instructions

provided.

1/8-in NPT x 90°

male elbow

clean-air plenum pressure

tap location

1/8-in NPT adapter

1/8-in NPT adapter

plenum tap location

3/8-in flat washer

1/8-in NPT coupling

mounting bracket

#6-32 x 1/4-in mounting screws

support structure

mounting surface

Magnehelic gauge

high-pressure port

low-pressure port

two, 1/8-in NPT

adapters

plastic tubing

two, 1/8-in NPT pipe plugs

two, self-drilling screws

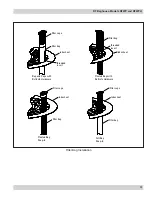

1/8-in NPT x 90° male elbow

dirty-air plenum pressure tap location

3/8-in flat washer

1/8-in NPT adapter

1/8-in NPT x 90° elbow

static pressure tee

Magnehelic Gauge Installation