Donaldson Company, Inc.

17

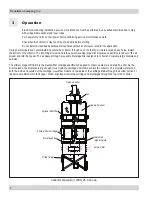

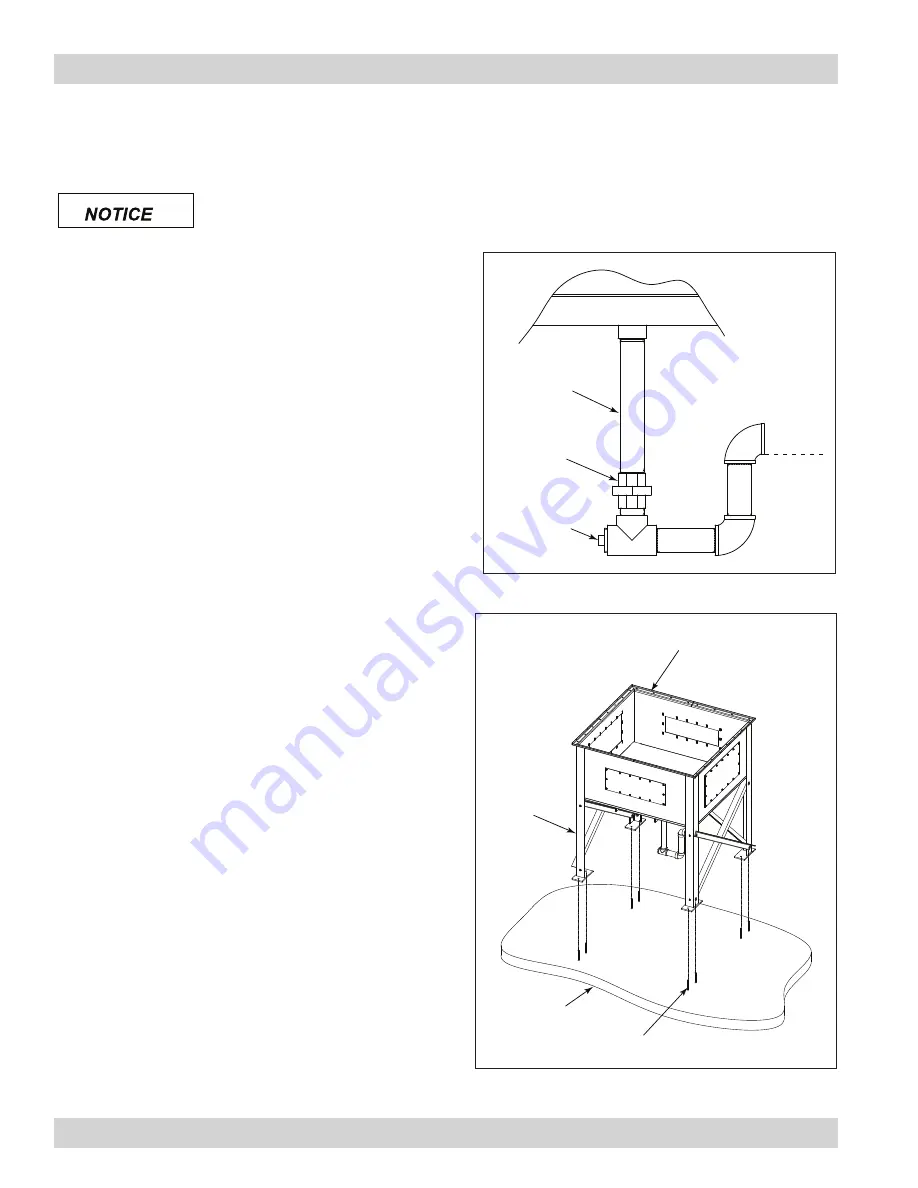

Inlet Plenum Installation

Reference Typical Foundation Anchor and leg assembly drawing

shipped with the collector prior to starting assembly.

1. Prepare the foundation or support framing in the selected

location. Locate and install anchors.

2. Using a crane or forklift, raise the inlet plenum to the required

height.

Note: When using a crane, use clevis pins and a sling

attached to four lifting lugs.

3. Lower the inlet plenum with legs to the anchor bolts.

4. Level inlet plenum and secure all hardware.

5.

Apply supplied sealant to the top flange of the inlet plenum.

6.

Remove the first stage and primary filters from the filter cabinet

and set aside.

7.

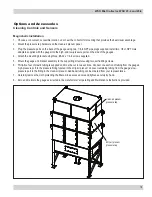

Using a crane or forklift, raise the filter cabinet section to

the required height. See below illustration for correct lifting

orientation.

8.

Set cabinet on top of the inlet plenum flange and attach with the

supplied fasteners.

9. Remove crane or forklift.

10.

Re-install the first stage and primary filters.

Inlet Plenum Installation, WSO 25-4 shown

leg

foundation

anchor bolt

inlet plenum

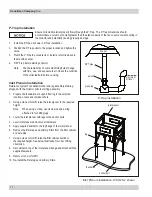

P-Trap Installation

Ensure collected material properly flows through the P-Trap. The P-Trap dimensions should

accommodate a column of coolant greater than the static capacity of the fan to avoid coolant pooling in

the collector and potentially causing property damage.

1. Install the P-Trap as shown in P-Trap Installation.

2. Position the P-Trap outlet to the proper location and tighten the

union.

3. Plumb the P-Trap to a receptacle or install a return line back to

the machine center.

4. Fill P-Trap before starting collector.

Note: The characteristics of some machining fluids change

with time, use, and exposure to air. Check the condition

of the collected fluid before re-using.

P-Trap Installation

maximum

fill level

hopper

NPT pipe

union

pipe plug