Torit PowerCore, TG 2 to TG 12

10

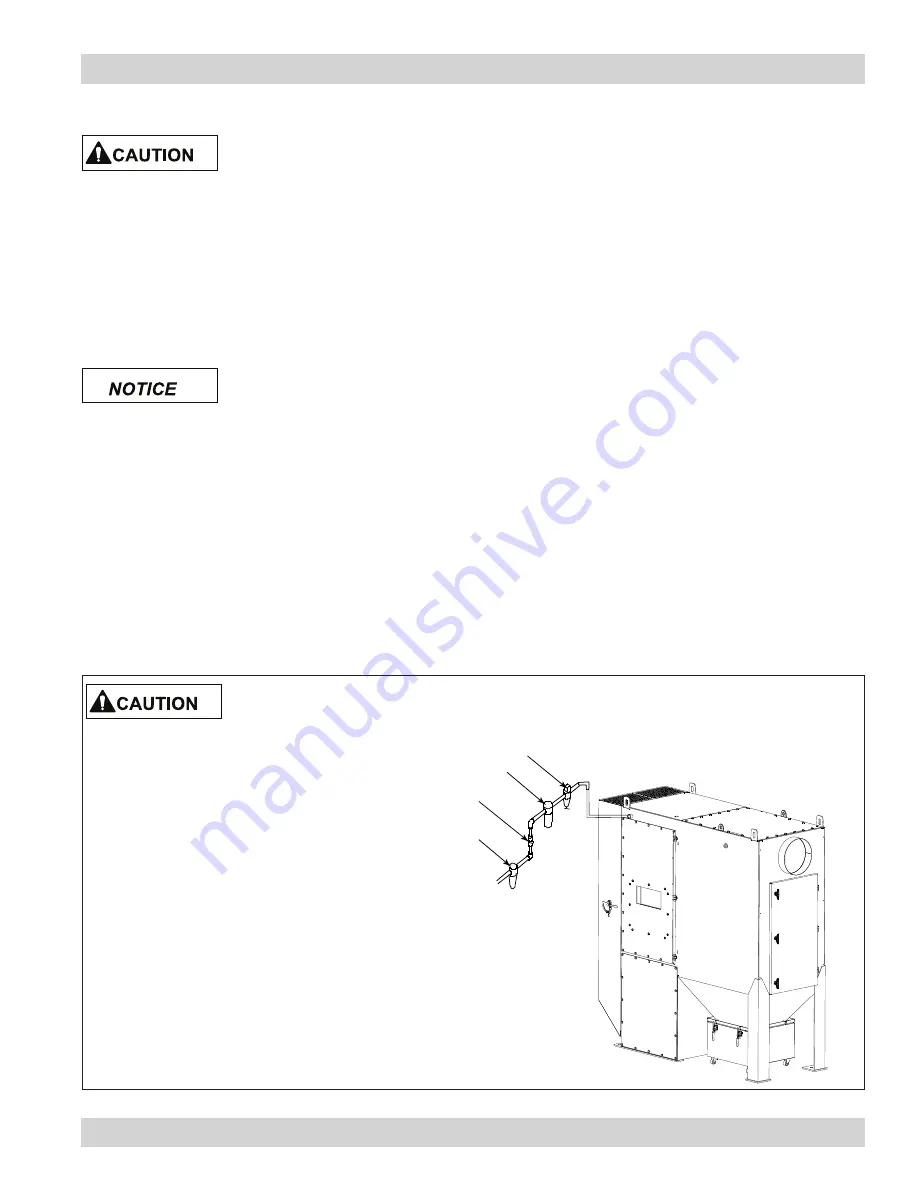

1. Remove the plastic pipe plug from the collector’s air

manifold and connect the compressed-air supply

lines. Use thread-sealing tape or pipe sealant on all

compressed-air connections.

2. Install a customer-supplied shut-off valve, bleed-

type regulator with gauge, filter, and automatic

condensate valve in the compressed-air supply line.

3. Set compressed-air supply to 90-psig. The pulse-

cleaning controls are factory set to clean one filter

pack every 10-seconds during each cleaning cycle

on the TG2 through TG8 and two filter packs every

10-seconds on the TG12.

air regulator*

bleed-type air filter*

automatic

condensate valve*

air supply line*

safety exhaust

valve*

*customer-supplied

Turn power off and lock out

electrical power sources.

Turn compressed air supply OFF, bleed

and lock out lines before performing

service or maintenance work.

Compressed Air Installation

Compressed Air Installation

Turn compressed air supply OFF,

bleed and lock out lines before

performing service or maintenance work.

A safety exhaust valve should be used to

isolate the compressed air supply. The safety

exhaust valve should completely exhaust

pressure in the collector manifolds when

closed, should be capable of being interlocked

with fire or explosion mitigation equipment

and should include provisions to allow closed-

position locking.

Do not set compressed-air

pressure above 100-psig as

component damage can occur.

All compressed air components must be sized

to meet the system requirements of 90-100-psig

supply pressure.

The compressed-air supply must be oil

and moisture free. Contamination in the

compressed air used to clean filters will result

in poor cleaning, cleaning valve failure, or poor

collector performance.

Purge compressed-air lines to remove

debris before connecting to the collector’s

compressed-air manifold.