INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

38

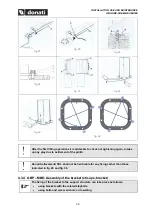

4.3.6 S profiles channel arm

4.3.7 Mounting of the trolley block inside the S profile channel arm

To correctly assemble the trolley block, first of all a suitable work environment is needed to drill the channel

profile. The correct drilling scheme is shown in the figure below (dis.1) and the dimensions can be found in

the following table

•

Arm S1: D2=32mm e

Φ=9.5mm

•

Arm S2: D2=50mm e

Φ=9.5mm

Arm length (m)

D1

2

3

4

5

6

7

Capacity

(kg)

63

430

490

590

650

125

360

430

430

490

590

650

250

360

430

500

530

590

650

500

400

460

460

530

620

690

800

690

1000

400

460

490

560

620

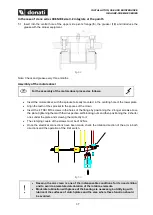

1. Trolley block

2. Fixing bolts

•

Before inserting the trolley block S1, tighten the provided blots (fig. 54) to realize

the seat for the head of the screws (fig. 55 e fig. 56) This passage will simplify the

next fixing operation becaus

e when the bolts are removed, the screws don’t move.

•

In trolley blocl S2 (fig. 58) the bolts are welded with the main body.

Internal trolley bumper S1

fig. 54

fig. 55

fig. 56

fig. 57

Internal trolley bumper S2

fig. 58

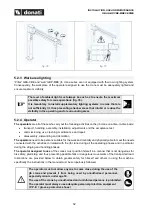

S1

S2

Capacity (kg)

Arm Length (m)

63

4-5

6-7

125

2-3-4-5

6-7

250

2-3-4

5-6-7

500

/

2-3-4-5-6-7

800

/

7

1000

/

2-3-4-5-6